Aluminum is a common metal element with many excellent properties such as light weight, corrosion resistance, and easy processing. Therefore, it is widely used in aerospace, transportation, construction, electronics and other fields.

Among them, the thermal conductivity of aluminum, as one of its important physical properties, often determines its performance in certain applications. This article will explore the thermal conductivity of aluminum, the factors affecting thermal conductivity, and its practical applications.

Introduction

Thermal conductivity refers to the ability of a substance to transfer heat. In materials science, thermal conductivity is an important parameter to measure the efficiency of a substance in conducting heat under the action of temperature difference. Metals generally have high thermal conductivity, and aluminum, as a metal, has relatively good thermal conductivity.

The thermal conductivity value of aluminum is about 235 W/(m·K), which is at a relatively high position among common metals. Compared with metals such as copper (about 401 W/(m·K)) and silver (about 429 W/(m·K)), aluminum has a slightly lower thermal conductivity, but its thermal conductivity is sufficient to meet the needs in many practical applications, especially in situations where high requirements are placed on material strength and weight.

Factors affecting the thermal conductivity of aluminum

The thermal conductivity of aluminum is not constant, and it is affected by many factors. The following are the main factors affecting the thermal conductivity of aluminum:

- Purity of the material

The purity of aluminum directly affects its thermal conductivity. Pure aluminum has a high thermal conductivity, but in actual production and application, aluminum is usually alloyed to increase its strength and hardness. The addition of different alloying elements will affect the thermal conductivity of aluminum. For example, aluminum alloys with copper, silicon, magnesium and other elements usually have a lower thermal conductivity because the addition of these elements may change the lattice structure and electron flow inside the material, thereby affecting the conduction of heat. - Temperature

The thermal conductivity of aluminum changes with temperature. Generally speaking, the thermal conductivity of aluminum is high at low temperatures, but as the temperature rises, its thermal conductivity will decrease. This is because as the temperature rises, the vibration of atoms or molecules in the metal intensifies, and the heat conduction efficiency is relatively reduced. In addition, under different temperature conditions, factors such as internal defects and grain boundaries of aluminum may also affect the conduction of heat. - Crystal structure of aluminum

The thermal conductivity of aluminum is also affected by its crystal structure. Aluminum has a face-centered cubic lattice structure, which is relatively common in metals and is more conducive to the conduction of heat. The thermal conductivity of a metal is usually related to the free electron density in its crystal structure, and the electronic structure of aluminum makes it have better thermal conductivity. - The state of the aluminum surface

The surface state of aluminum is also a factor affecting its thermal conductivity. Aluminum with a smooth surface can provide a better thermal conduction path because the smooth surface reduces thermal resistance. The aluminum oxide layer will form a barrier with a large thermal resistance, reducing the conduction of heat. Therefore, if a thick oxide film is formed on the surface of aluminum during use, its thermal conductivity will decrease. - Alloy composition and processing method

There are many types of aluminum alloys, and different alloy compositions and processing methods will affect their thermal conductivity. For example, adding more copper elements will significantly reduce the thermal conductivity of aluminum, while some special aluminum alloys can minimize thermal conductivity loss while maintaining high strength by optimizing the alloy composition.

Analysis of the application

The thermal conductivity of aluminum makes it an important material in many fields. In the following applications, the thermal conductivity of aluminum is particularly important.

- Electronic radiator

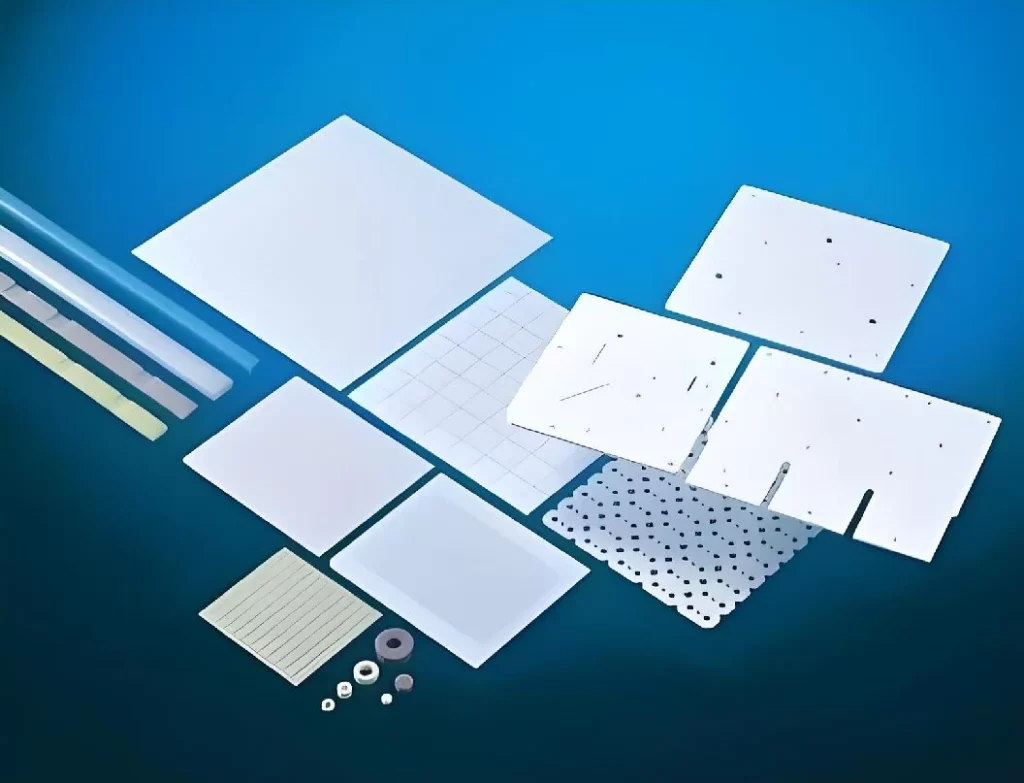

In electronic products, electronic components usually generate a lot of heat when working. Excessive temperature will affect the performance of the equipment and even cause damage. Therefore, an efficient heat dissipation system is required to quickly conduct and dissipate the heat. Aluminum has become a common material for electronic radiators, heat sinks and heat dissipation devices due to its good thermal conductivity and relatively light weight. For example, the radiators in computer CPUs and LED lamps are mostly made of aluminum to improve heat dissipation efficiency. - Automobile industry

In the automotive industry, especially in engines, brake systems and other high-temperature working environments, the thermal conductivity of aluminum plays a vital role. Aluminum helps transfer and dissipate heat, thereby improving engine efficiency and preventing overheating. Aluminum alloys are widely used in the cooling system of automobile engines because they not only have high thermal conductivity, but also have good corrosion resistance and low weight, which optimizes the overall design. - Aerospace

In the aerospace field, the thermal conductivity of aluminum plays an important role in the design of aircraft fuselages. Since aircraft experience drastic temperature changes during flight, aluminum can effectively disperse the heat generated by the fuselage and ensure that the structure of the aircraft remains stable during changes between high and low temperatures. In addition, the lightweight characteristics of aluminum are also one of the important reasons for the widespread use of aluminum in the aerospace field. - Heat exchangers

Heat exchangers are widely used in many fields such as industry, energy, and refrigeration. Their main function is to exchange heat through aluminum pipes or fins to achieve the effect of heating or cooling. Due to the good thermal conductivity of aluminum, it can effectively conduct heat, improve heat exchange efficiency, and ensure that the equipment operates in a high-efficiency state. Aluminum is used as a heat exchange material in many air-conditioning systems, cooling towers, and industrial equipment. - Building materials

The use of aluminum alloys in building materials is also closely related to its thermal conductivity. Building materials such as aluminum alloy window frames and curtain wall systems use the thermal conductivity of aluminum to help buildings maintain a good temperature balance. Especially in energy-saving building design, aluminum alloy window frames can help reduce heat loss, thereby improving energy efficiency. In addition, the weight advantage of aluminum alloys in building structures also helps to reduce the overall weight of the building and optimize the building design.

How to improve the thermal conductivity of aluminum

Although the thermal conductivity of aluminum is relatively good, in some high-demand applications, it is still necessary to improve its thermal conductivity in a certain way. The following are several common ways to improve the thermal conductivity of aluminum:

- Increase purity

Increasing the purity of aluminum is a way to improve its thermal conductivity. The thermal conductivity of pure aluminum is significantly better than that of aluminum alloys containing other elements. Therefore, in some special applications, the use of high-purity aluminum can achieve better heat conduction effects. - Use alloy optimization technology

By selecting appropriate alloying elements and optimizing the alloy formula, the thermal conductivity of aluminum alloys can be maintained or improved to the greatest extent while maintaining the strength of the aluminum alloy. For example, some aluminum alloys can enhance the strength and corrosion resistance of the material without significantly reducing the thermal conductivity by adding a small amount of magnesium or silicon. - Surface treatment technology

Surface treatment methods of aluminum, such as electroplating and anodizing, can reduce the thickness of the surface oxide film, thereby improving the thermal conductivity of aluminum. At the same time, these surface treatment methods can also improve the corrosion resistance of aluminum and extend its service life. - Nanotechnology

In recent years, the application of nanotechnology has provided a new way to improve the thermal conductivity of aluminum. By adding nanomaterials (such as nanocarbon tubes, nanoparticles, etc.) to aluminum, its thermal conductivity can be significantly improved. These nanomaterials can improve the heat conduction path at the microscopic level and improve the overall thermal conductivity efficiency.

Conclusion

As an important metal material, aluminum has been widely used in many fields due to its excellent thermal conductivity. Whether in electronic equipment, automotive industry, aerospace, or in construction and heat exchange systems, the thermal conductivity of aluminum has played a vital role. With the development of science and technology, we can expect more innovative aluminum alloys and new technologies to further improve the thermal conductivity of aluminum to meet the growing industrial needs.

The thermal conductivity of aluminum is not only an important indicator of its physical properties, but also an important factor in promoting technological progress in many fields. By optimizing the formula of aluminum alloys, improving the purity of materials and adopting emerging technologies, we are expected to further expand the application of aluminum and provide more efficient and reliable solutions for various industries.