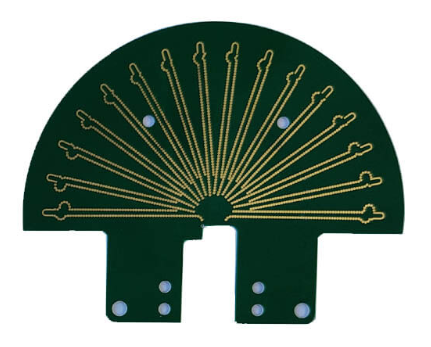

Thick copper PCB is a special type of printed circuit board commonly used in the electronics industry, which has a large current carrying capacity and good heat dissipation properties.

Thick copper PCB use FR-4 as the basic material, and the thickness of copper foil is generally 1oz or more. Through a special process, the thickness of the copper foil is thickened to 2oz, 3oz, 4oz and 5oz levels, or even higher. This type of PCB can also be used as an aluminum substrate (MCPCB), copper substrate, ceramic substrate, and flexible substrate, among others.

PCB Thick Copper is a circuit board with excellent conductivity, load carrying capacity and heat dissipation properties, and is therefore widely used in a number of areas.

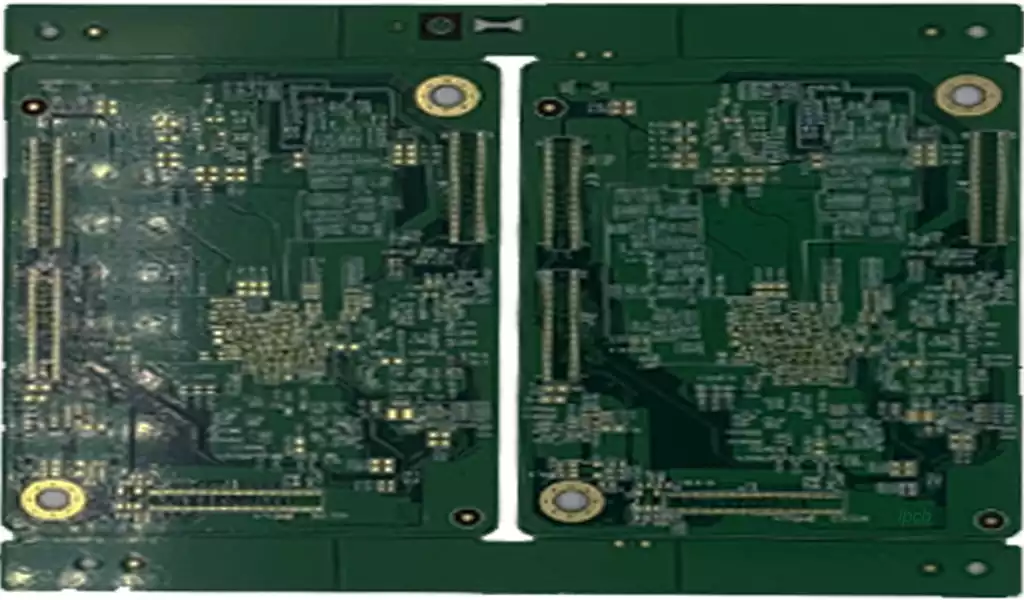

High-power electronic devices: These boards are able to withstand high currents and have good heat dissipation properties, so they are widely used in high-power electronic devices. For example, in equipment such as power supplies, LED lighting, inverters and charging piles, it can provide stable current transmission and effective heat dissipation to ensure efficient and stable operation of the equipment.

Communication field: In communication equipment, it can provide stable signal transmission and processing capability, and is widely used in base station equipment, communication modules and other key components to support high-speed data transmission and large-scale computing.

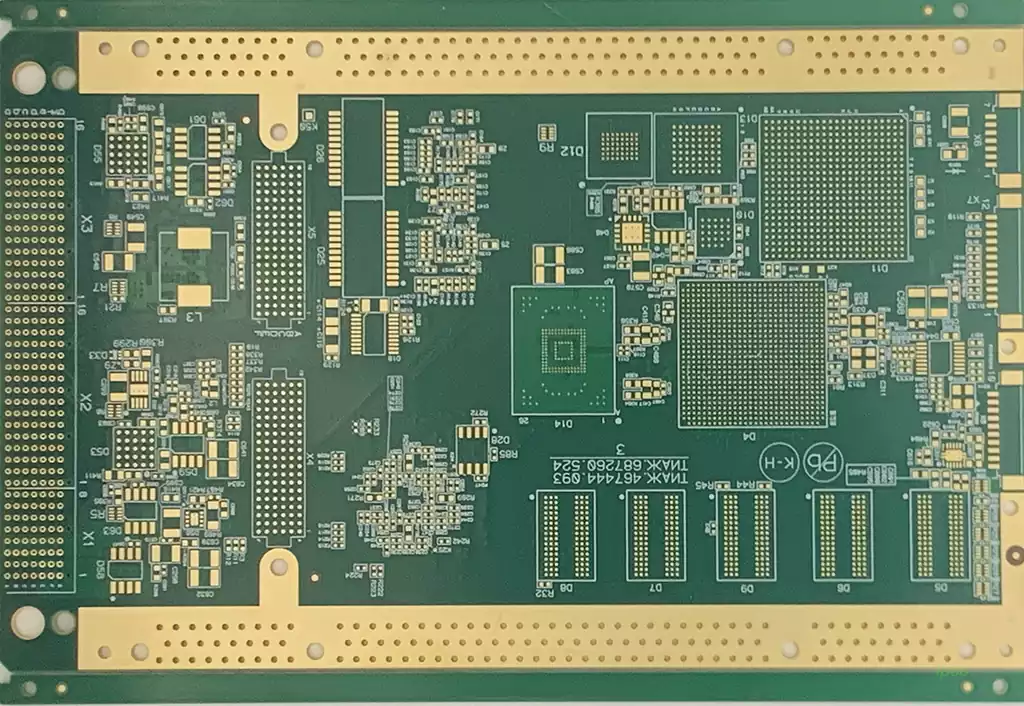

Medical equipment: In circuit boards for medical equipment, it provides stable current transmission and efficient heat dissipation to ensure the normal operation of the equipment and the safety of patients.

Industrial control equipment: In industrial control equipment, Thick copper PCB is widely used in various controllers, sensors and actuators and other key components. It can withstand harsh industrial environments, provide stable circuit connections and heat dissipation performance, and ensure the normal operation and productivity of the equipment.

Automotive electronics: Automotive electronic equipment has extremely high performance requirements for circuit boards, the boards provide a stable and reliable operating environment for automotive electronic equipment with its excellent conductivity and heat dissipation performance. It is widely used in automotive battery management systems, inverters and other key components to ensure the safety and comfort of the car.

Special processing requirements for thick copper plate

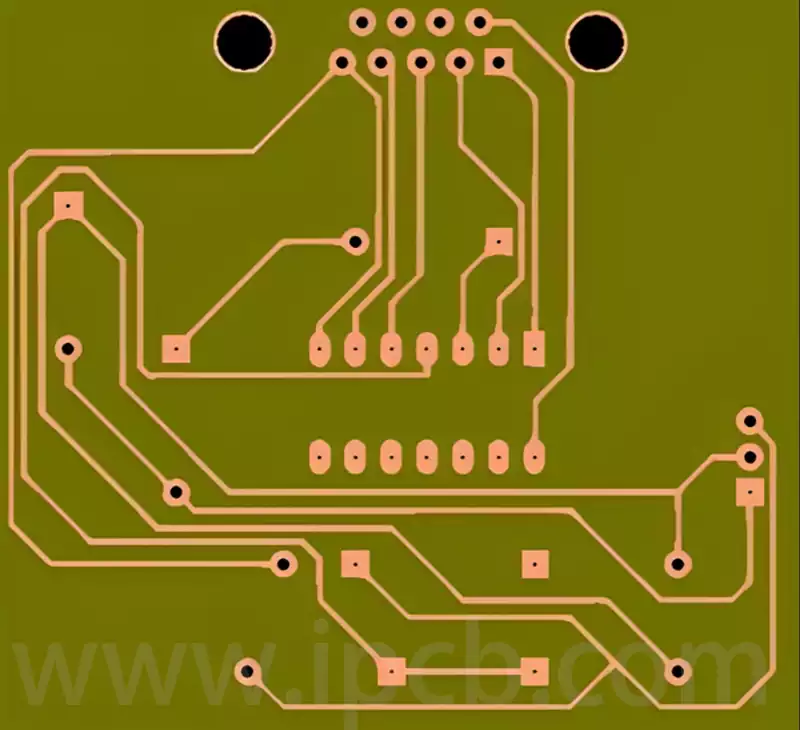

- Material selection: High-quality copper material should be selected to ensure its current carrying capacity and thermal conductivity. It is generally recommended to choose copper materials with high purity and good surface finish.

- Thickness control of copper foil: The thickness of copper foil is usually above 70um, so the thickness of copper foil needs to be strictly controlled during the manufacturing process to ensure stable current transmission and heat dissipation.

- Line width and line spacing design: Since this kind of pcb board needs to carry large current, line width and line spacing should be considered in the design to ensure the normal transmission of current and prevent overheating.

- Soldermask treatment: Soldermask requires special treatment to ensure its adhesion to copper foil and thermal conductivity. In the manufacturing process, solder resist materials with good high temperature tolerance need to be selected and properly treated to improve the adhesive strength between it and the copper foil.

Thick copper pcb is a solid backing for the stable operation of electronic equipment, and its unique conductivity, carrying capacity and heat dissipation properties provide a stable and efficient operating environment for high-performance, high-reliability electronic equipment.