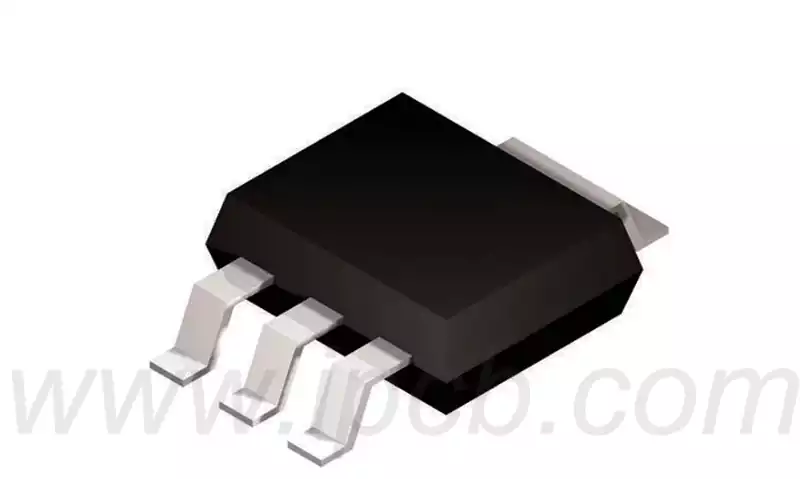

Transistor surface mount, also known as chip transistors, are developed from conventional plug-in transistors, which have the same core, only the package is different, and most of them follow the plug-in transistor’s prototype number. Transistors are smaller in size and lower in profile than traditional through-hole transistors.

Transistors are one of the crucial semiconductor components in the field of electronics and are widely used in electronic systems such as amplifier circuits, switching devices and signal modulation.Transistors are divided into two main categories: bipolar transistors (BJTs) and metal oxide semiconductor field effect transistors (MOSFETs).The following is a brief description of these two types of transistors and their characteristics:

Bipolar Transistor (BJT):

Divided into NPN and PNP structures.

It consists of two PN structures,the emitter,the base and the collector.

Working Mechanism: Adjust the base current to affect the collector current to achieve the effect of amplification or switching.

Characteristics:

Demonstrates positive feedback effect and provides high current amplification.

Operates relatively slowly, which is related to the charge carrier diffusion and drift processes it involves.

Energy consumption is high because a certain base current is required to control the collector current.

Metal Oxide Semiconductor Field Effect Transistor (MOSFET):

Includes enhancement and depletion types,with the enhancement type subdivided into N-channel (N-Channel) and P-channel (P-Channel).

The structure consists of Source, Drain and Gate.

Principle of operation: by applying a voltage to the gate to control the conductive channel between the source and drain,to achieve the function of amplification or switching.

Characteristics:

Has a high input impedance due to the presence of an insulating layer between the gate and the source/drain.

Operates faster because its control mechanism relies on an electric field rather than the movement of charge carriers.

Low energy consumption, especially in the non-conducting state, which consumes almost no energy.

Easily integrated and well suited for the fabrication of large-scale integrated circuits.

JFET (Junction Field Effect Transistor)

JFETs are another type of field effect transistor known for its high input impedance and low noise characteristics. It is suitable for high frequency and low noise application scenarios.

High Frequency Transistors

Designed for high frequency signal processing,these transistors are commonly used in wireless communications and RF applications.They typically have a wide frequency response.

Small Signal Transistors

Small signal transistors are mainly used for signal processing and amplification and are widely used in audio amplifiers and signal amplification circuits.

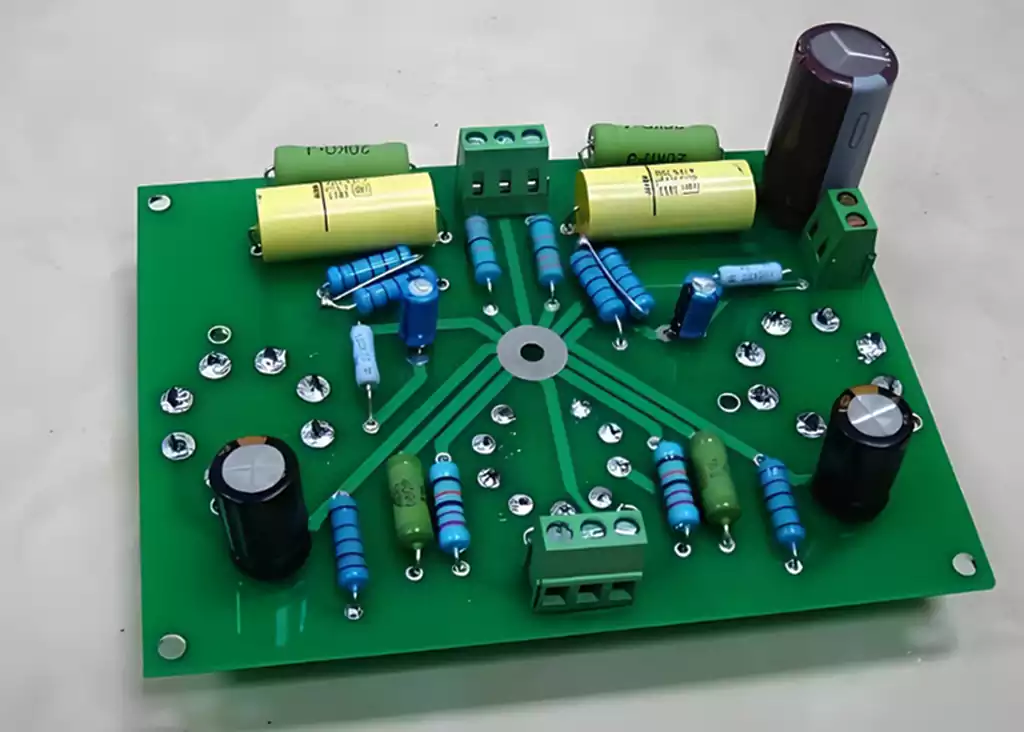

Power Transistors

Power transistors are used to handle higher currents and voltages and are suitable for high power applications such as motor control and power conversion.

RF Transistors

RF transistors are specially designed for RF signal processing and are widely used in communication systems and radio transmitters.

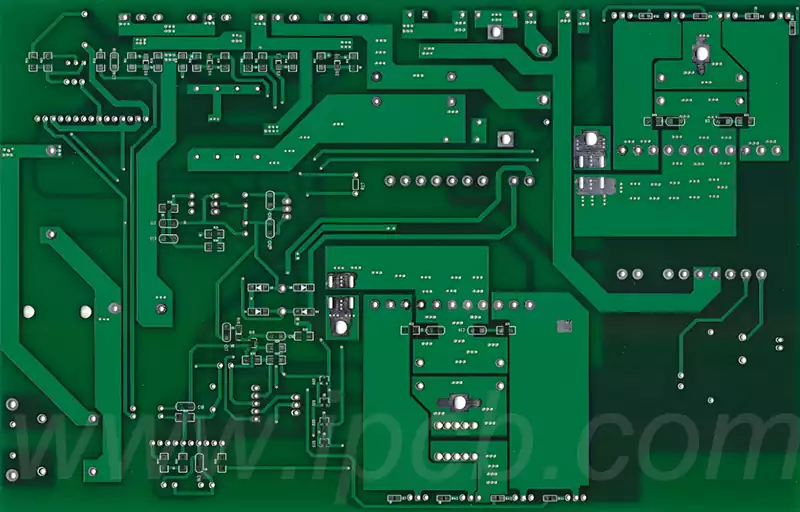

Transistor surface mount advantages:

Small size and light weight: transistor surface mount is usually packaged in small packages, such as SOT-23, SOT-89, etc., which can effectively reduce the occupied area of the circuit board and the weight of the overall equipment on the basis of ensuring performance.

Automated production: Surface mount technology supports highly automated production processes,which can significantly improve productivity and consistency and reduce labour costs. This feature makes mass production possible and ensures consistent product quality.

Improved Electrical Performance: With smaller solder joints, designs can be made with reduced lead lengths,which reduces parasitic inductance and capacitance and improves high-frequency characteristics. This is particularly important for circuits requiring fast switching response,such as high frequency communications and RF applications.

Transistor surface mount technology has been widely used in the following areas:

Consumer electronics: In consumer electronics such as smartphones, tablets and laptops, surface mount technology for transistors can effectively reduce product size and improve portability.

Automotive electronics: A large number of electronic components are integrated in modern automobiles, such as ADAS (Advanced Driver Assistance System), powertrain control units, etc., which require the use of surface-mounted transistors to meet the requirements of miniaturisation and high performance.

Communication equipment: In network equipment and communication infrastructures, the high-frequency characteristics and compact layout of transistors optimise signal transmission and enhance data processing.

Transistor surface mount differ significantly from conventional Leaded Transistors (THT) in terms of manufacturing costs and applications:

Manufacturing Costs

Surface Mount Technology (SMT) significantly reduces manufacturing costs due to its high level of automation, as SMT implants are soldered directly to the board surface by automated machines, reducing the time and cost of manual soldering. In contrast, traditional leaded transistors (THT) require components to be inserted into holes in the circuit board and soldered manually, a method that is time-consuming and increases labour costs. As a result, SMT has shown to be more cost-effective for mass production.

Packaging Material Costs

In terms of material costs, SMT’s design allows it to reduce the need for large leadframes and therefore save money on packaging materials. Conventional leaded transistors typically require more metal to fabricate the leadframes, which increases the overall material cost. As technology advances, SMT allows for smaller passive components, resulting in a streamlined overall component size and a corresponding reduction in material costs.

Labour Costs

In terms of labour costs, the production process for SMT is relatively simple as most of the steps can be automated, reducing the need for human intervention. On the contrary, THT requires more manual intervention in the assembly process, which directly leads to higher labour costs. Despite the higher initial investment in SMT equipment, costs can be effectively spread through mass production, ultimately reducing manufacturing costs per unit of product.

The future development trend of transistor surface mount technology

- Miniaturisation and high-density integration

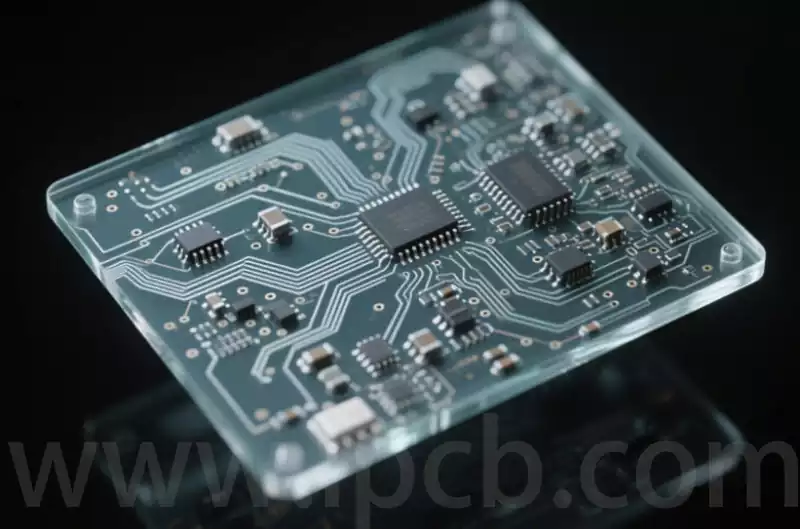

In the future, the demand for miniaturisation and high-density integration of electronic equipment will continue to increase. Transistor surface mount technology by reducing the size of the components and reduce the pin spacing, making the circuit board wiring more compact, which will further promote the development of electronic products to portable and lightweight direction. With the advancement of manufacturing processes, it is expected to appear smaller package forms, such as 0201 size passive components, which will help achieve higher component density and optimise PCB design. - Application of advanced packaging technology

Advanced packaging technologies, such as 3D encapsulation, chip-scale packaging (CSP) and flip-chip soldering (Flip Chip), will be increasingly used in the transistor surface mount process. These technologies can improve transistor performance and integration, reduce latency and power consumption for applications that require high performance, such as artificial intelligence and high-performance computing. It is expected that these advanced packages will be a key factor in driving a new wave of innovation in surface mount technology. - Promotion of environmentally friendly soldering technology

With the global environmental awareness, the application of lead-free soldering technology will become the main trend of implementation. This technology not only meets the requirements of environmental regulations, but also can effectively reduce the production process of harmful substances. In the future, lead-free soldering may become the mainstream soldering method of SMT, promoting the green transformation of the entire industry. - Intelligent manufacturing and automation

Automation and intelligent manufacturing will revolutionise transistor surface mount technology. The introduction of Artificial Intelligence (AI) technology can optimise the production process and improve production efficiency and product quality through real-time monitoring and adjustment. In addition, further development of automated placement equipment will help reduce human error and improve overall assembly accuracy. - Expansion of application areas

The application fields of transistor surface mount technology are expanding, especially in the fields of consumer electronics, automotive electronics and medical devices. With the rise of automotive electrification and Internet of Things (IoT) technology, SMT will play an even more critical role in these emerging fields. For example, the demand for lightweight and high-efficiency components in electric vehicles will further drive the development of SMT technology.

As one of the core processes in modern electronics manufacturing, transistor surface mount technology not only demonstrates significant advantages in miniaturisation, automated production, and electrical performance enhancement, but also continues to drive the development of electronic products in the direction of higher performance, lower power consumption, and environmental protection.