Printed circuit boards (PCBs) are the foundation of modern electronics, and their manufacture involves a wide range of materials and chemicals. However, as environmental awareness grows, global requirements for PCB production are becoming “greener” to minimize harm to the environment and human health. RoHS compliant PCBs have emerged to not only meet the strict environmental standards, but also to fulfill the requirements of modern manufacturing. What is rohs pcb board? In this paper, we will discuss the background, standards, production process and its significance to the electronics industry of RoHS-compliant PCB boards.

RoHS is the abbreviation of “Restriction of Hazardous Substances”, meaning “Restriction of Hazardous Substances”. This is the first environmental protection regulation issued by the European Union in 2003, aiming to reduce the use of certain hazardous substances in electrical and electronic equipment.RoHS 1.0 specification restricts the use of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE) and other six substances, and with the update of the RoHS, the RoHS 2.0 in 2015 on the basis of the original specification to increase the use of four kinds of phthalates (DEHP, BBP, DBP, and DIBP) to the original specification, which makes the production of RoHS-compliant PCB boards more stringent in material selection.

RoHS compliant PCBs are mainly used in the European market as well as in other countries and regions worldwide that follow the RoHS standard. Through the development of such specifications, RoHS has made a positive contribution to global environmental protection, but also prompted the global electronics manufacturing industry to the direction of environmental protection.

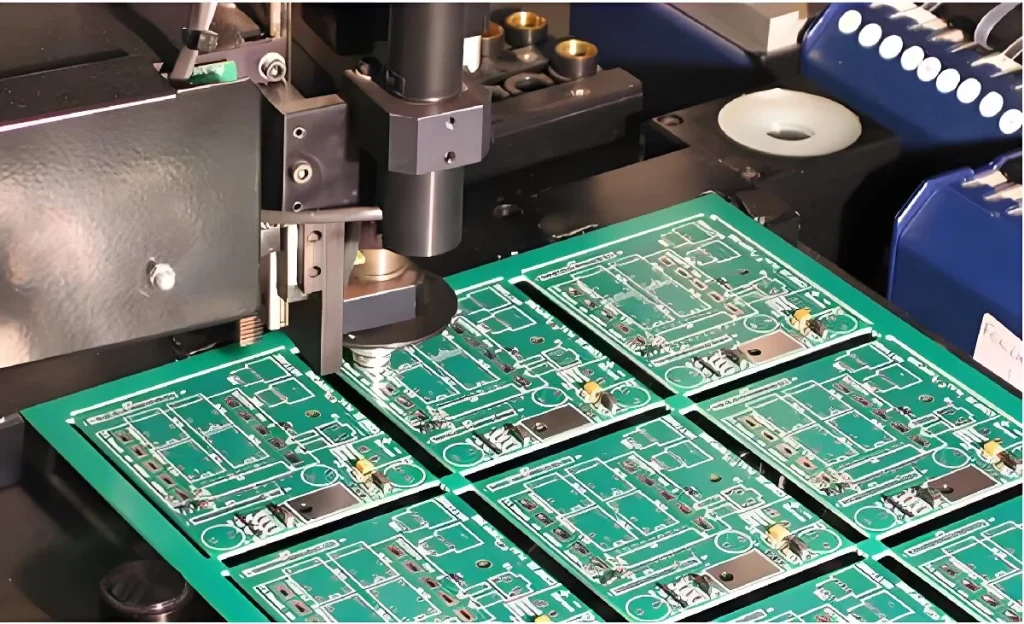

RoHS-compliant PCB manufacturing process

Many Manufacturing RoHS-compliant PCB boards not only need to meet the structural and performance requirements, but also strictly control the composition of the materials used to ensure compliance with environmental standards. In the production process, the choice of materials, process control and final testing is critical.

Material Selection

RoHS compliant PCBs are very careful in material selection. In order to avoid the use of leaded solder, manufacturers usually use lead-free solder instead, which are mostly tin-copper, tin-silver-copper or tin-bismuth alloys. In addition, the RoHS specification limits the amount of hazardous substances in plating and PCB body materials, so many manufacturers have adopted new environmentally friendly materials to ensure compliance with the strict requirements of RoHS.

Lead-free soldering process

Lead-free soldering process is one of the key technologies for RoHS compliant PCBs. Due to the high melting point of lead-free solder, this requires the soldering process to be performed at a higher temperature. However, high-temperature soldering is prone to damage PCB boards and components, so extra care needs to be taken when designing the process to ensure uniform temperatures and avoid material aging and board deformation. The lead-free soldering process, although more demanding in terms of equipment and technology, is globally accepted for its environmental and health benefits.

Modification of production equipment

In order to adapt to the requirements of lead-free soldering, RoHS-compliant PCB board production requires equipment modification. The high temperature of lead-free soldering requires necessary adjustments in equipment such as soldering machines and reflow ovens to adapt to the melting temperature of the new solder. Equipment upgrades raise the cost of production of RoHS compliant PCB boards, but in the long run, it helps to improve process quality and environmental protection.

Final Testing and Certification

RoHS-compliant PCBs undergo rigorous testing and certification before they leave the factory to ensure that there are no excessive residues of hazardous substances. These tests include X-ray fluorescence spectrometer (XRF) testing, composition analysis, mechanical performance testing, etc. RoHS certification is an important symbol of product compliance with environmental standards, with RoHS-certified PCB boards can smoothly enter the global market and reduce export risks.

The advantages of RoHS-compliant PCBs

RoHS compliant PCB is not only to deal with the requirements of environmental regulations, itself also has a variety of advantages:

Environmentally friendly

RoHS regulations by strictly controlling the use of hazardous substances, greatly reducing the PCB board on the environment and health threats. The production process reduces the emission of heavy metals and toxic chemicals, which reduces the amount of hazardous substances in e-waste from the source, and significantly reduces the degree of pollution to soil and water when electronic products are discarded.

Global Market Access

Many countries and regions require imported electronic products to be RoHS compliant. RoHS-compliant PCBs can directly enter the European market and other national markets that follow RoHS standards, avoiding trade barriers due to non-compliance with environmental requirements. For electronic manufacturing enterprises, the use of RoHS compliant PCBs is an important means to improve international competitiveness.

Enhancement of corporate image

RoHS compliant PCB manufacturers not only comply with market demand, but also contribute to environmental protection. Environmental responsibility can not only enhance the social image of enterprises, but also increase the user’s recognition of the product. Modern consumers are increasingly concerned about corporate environmental responsibility, RoHS-compliant products are more likely to gain market favor.

Extend product life

Although lead-free solder has a higher melting point, it has better soldering performance, which can improve the oxidation resistance and soldering strength of PCB boards, and thus extend the service life of products. In addition, RoHS-compliant materials have advantages in corrosion resistance and abrasion resistance, which helps to improve the reliability of the PCB board.

RoHS-compliant PCB board application areas

RoHS compliant PCBs are widely used in many industries:

Consumer Electronics

RoHS compliant PCBs are widely used in consumer electronics products such as smartphones, tablet PCs and laptops. Due to the short replacement cycle of consumer electronics, the number of discarded electronic products is huge, RoHS compliant PCBs help reduce the impact of electronic waste on the environment.

Automotive Electronics

The automotive industry has high requirements for safety and reliability, and RoHS compliant PCBs can meet the environmental and performance needs of automotive electronic systems. With the rapid development of electric vehicles and autonomous driving technology, RoHS compliant PCBs have become an important part of automotive electronics.

Medical Devices

Medical equipment has a direct impact on human health, and RoHS compliant PCBs will not have a detrimental effect on patients and medical staff when used in medical equipment. In addition, the medical industry has strict requirements for product quality and environmental protection, and RoHS compliant PCBs have become the preferred material for medical equipment manufacturing.

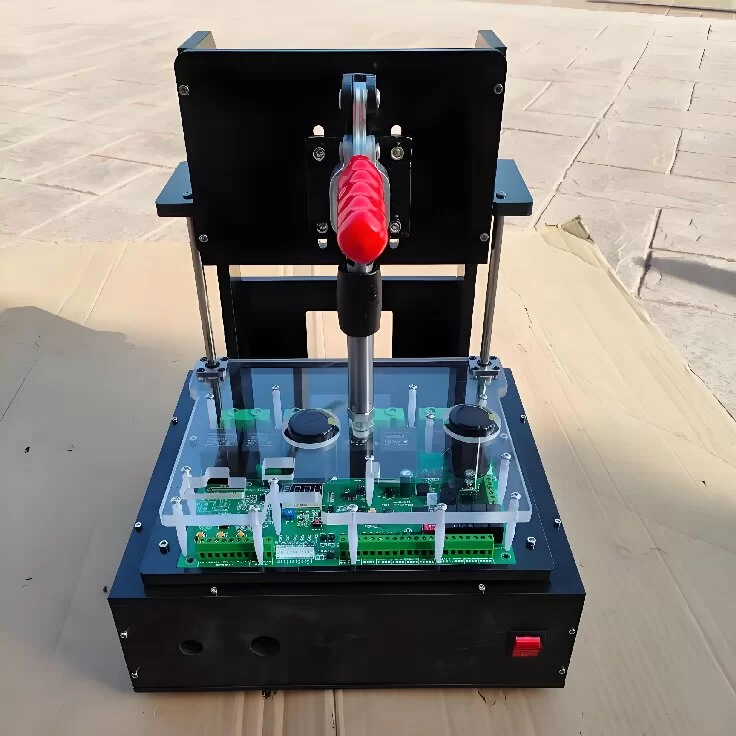

Industrial Control Equipment

Circuit boards in industrial control equipment are often exposed to high temperatures, humidity and other harsh environments. RoHS compliant PCB due to the use of lead-free soldering process and environmentally friendly materials, to better adapt to the needs of the industrial environment and improve the reliability of the equipment.

RoHS-compliant PCB board of future development trends

With the increasingly stringent global environmental standards, RoHS-compliant PCB boards will be further popularized in the future, and presents the following development trends:

Technological innovation

With the development of environmental technology, PCB manufacturing process and materials will be further optimized. RoHS compliant PCB board manufacturers will continue to develop more environmentally friendly and efficient materials and processes to meet the growing market demand. For example, non-toxic materials based on water-soluble coatings have been gradually applied in the manufacturing of PCB boards, bringing new development space for RoHS compliant PCB boards.

Expanding the scope of application

Currently, RoHS-compliant PCBs are mainly used in consumer electronics and automotive electronics, and will be gradually expanded to aerospace, defense and other high-tech industries. The application of RoHS compliant PCBs in these areas will bring new opportunities for environmentally friendly manufacturing, and will further enhance product performance and reliability.

Cost control

Although the RoHS compliant PCB board production costs are high, but with technological advances and market expansion, the future cost will be gradually reduced. RoHS compliant PCB boards will become more popular and competitively priced, further promoting the green development of the global electronics industry.

Promoting global environmental policy development

The popularization of RoHS-compliant PCBs will also promote the development of global environmental policies. In the future, more countries may refer to RoHS to develop local environmental standards to promote the green transformation of the domestic electronics manufacturing industry. In this context, RoHS-compliant PCBs are expected to further promote the development of global environmental protection industry.

Summary

RoHS-compliant PCB boards not only meet the environmental standards, but also widely used around the world. Through the lead-free soldering process, the use of environmentally friendly materials and strict testing and certification, these PCB boards effectively reduce the impact of hazardous substances on the environment. As technology continues to advance and market demand changes, RoHS-compliant PCBs will play an increasingly important role in the future of the electronics industry.

For manufacturers, investing in RoHS-compliant PCBs is not only a response to regulatory requirements, but also an important step towards sustainable development. Through green manufacturing, companies can enhance market competitiveness, improve brand image, and make positive contributions to the sustainable development of mankind.

In the future development, RoHS compliant PCBs will continue to lead the green revolution in the electronics industry and promote the development of global environmental protection.