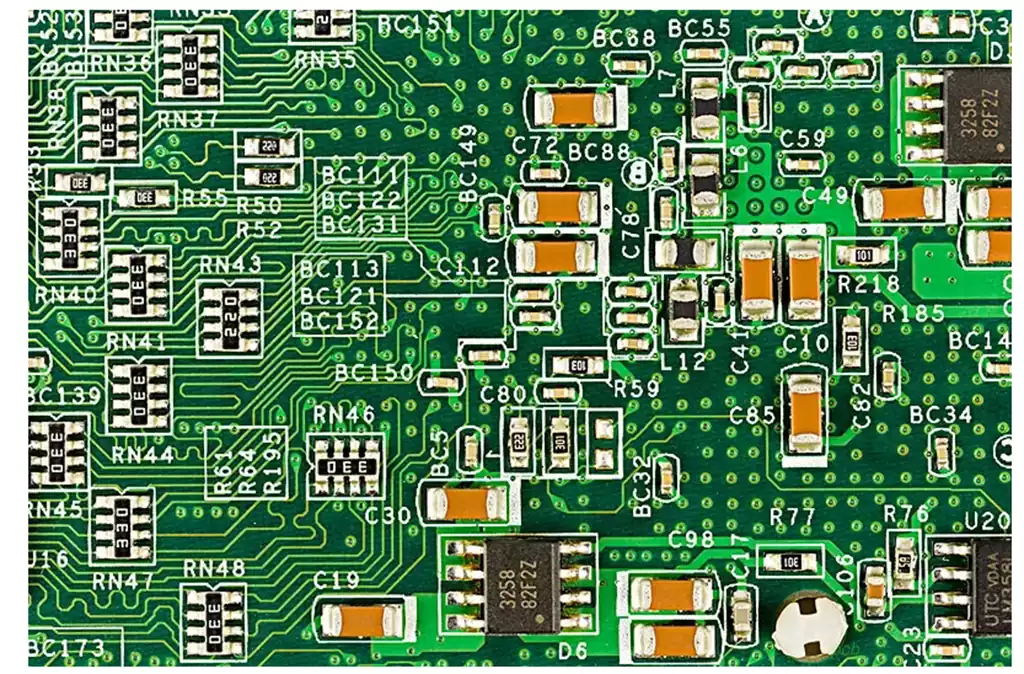

Inside electronic devices, we often come across an unassuming green component – the printed circuit board (PCB). So why are PCBs green?The green part is called solder resist, the composition is resin and pigment, green is green color pigment, there are also various other colors, and decoration tuning paint no difference. The reason why the circuit board appears green is related to its material. The actual circuit board is not green, but a printed material called solder resist. This is a layer of solder-resistant resin that is printed on the part of the circuit board that does not adsorb or solder solder.

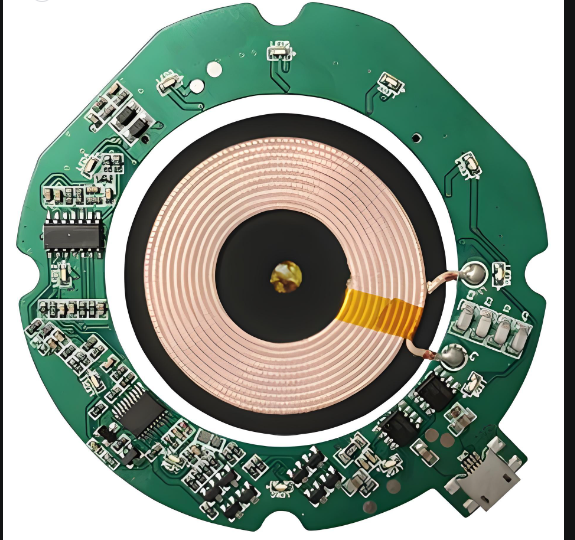

Printed circuit boards are usually composed of pads, vias, solder resist layers, silkscreen layers, copper wires, various components and other parts. Among them, the solder resist layer (solder mask) refers to the part of the printed circuit board to be on the green oil. In fact, solder resist ink is not only green, there are red, yellow, blue, purple, black, etc., but green is the most common. Group welding is not printed on the board before the paste can flow, printed on the board, and finally to “curing”, so that the resin hardened by heat curing. The purpose of soldermask is to protect the board from moisture, oxidation and dust. The only place that is not covered by soldermask is usually said to be the pads, which are used to solder the solder paste. This prevents the formation of poor quality such as soldering short circuits between IC pins, and in the old days of wave soldering, it prevents short circuits between the circuit board components and device pins, etc.

Green is a pigment in the resin formulation. Green was specifically chosen as an aid to human inspection of PC boards. This may be a factor in very dense designs, but for most PCBs, Green is just the default setting: unless you make a special request to the PCB manufacturer when you order the product, the board you receive will be green.

Printed circuit boards aren’t actually green all the time; the only green part is the resin shell, also known as soldermask or solder resist, which is a hardened resin with colored pigments that is applied to the board in a screen-printed manner, while the soldermask is intended to protect the electronics underneath from moisture and dust and to control the flow of molten solder.

Solder resist prevents PCB oxidation to a certain extent, but it does not completely prevent the occurrence of oxidation.

In PCB manufacturing, the application of solder resist has two main roles:

- Prevent the circuit board from being oxidized

Circuit boards are easy to oxidize when in contact with air and show a bright and yellow and discoloration of the phenomenon, this phenomenon will lead to circuit board damage. Soldermask through the formation of a protective film on the surface of the PCB, can effectively prevent the circuit board from contacting the air to avoid oxidation. - Prevent short circuit

Short circuit between the pad and the welding line is an important issue in PCB manufacturing, solder resist through the formation of a layer of thin film on the pad to prevent the liquid flow of molten solder between the pads, thus avoiding short circuits between the pads.

The core of a typical FR-4 circuit board is, in fact, a dull yellow, but the soldermask can come in a variety of colors, such as blue, red, yellow, black, and white, and even have the luxury of using more exotic colors, such as orange, pink, purple, matte, or a mixed-color board, so the question is, “Why are pcbs green?”

First of all, the appearance of green pcb board is closely related to the materials used. Typically, the substrate material of the circuit board consists of glass fiber reinforced epoxy resin. This material is not only non-toxic, odorless and chemically resistant, but also presents itself as a light or dark green color. Therefore, when this material is used to make printed circuit board, its color is naturally inherited.

Secondly, the choice of green pcb also has its practical considerations. Green has good contrast, making it easier to identify and solder electronic components on circuit boards. Green also has better reflective properties than other colors, which helps to improve productivity and reduce errors in the manufacturing process.

In addition, green pcb board is environmentally friendly. Epoxy resin is an environmentally friendly material, and the color green is often seen as a symbol of nature and the environment. Therefore, the choice of green as the color of the circuit board also reflects the concern for environmental protection.

PCB green is also easier to identify and mark during the manufacturing process of electronic devices. Manufacturers can print or add special markings to differentiate between different electronic components and connections, thereby reducing errors and confusion during the assembly process.

Finally, green pcb board has become a standard choice in the industry. Over the past few decades, most electronic equipment manufacturers have favored green circuit boards. This choice has been widely accepted in the marketplace and is considered the norm within the industry. As a result, even if other colors of circuit boards were technically permissible, they would probably not be widely adopted because green has become the traditional and accepted choice.

The preference for green in printed circuit boards is the result of a combination of factors, including their material properties, practicality, environmental awareness and industry standards. As a key part of electronic device manufacturing, green pcb has become a common and reliable choice. It promotes the development of the electronics industry as well as environmentally friendly manufacturing.