Printed Circuit Boards (PCBs) are the backbone of electronic devices, providing mechanical support and electrical connections for components. When you think of a PCB, the classic green color might come to mind. But why green, and what are the benefits of using green PCB boards? In this article, we will delve into the reasons behind the iconic green hue and explore the advantages that green PCB boards offer to both manufacturers and consumers.

Why Are PCB Boards Green?

The distinct green color of PCBs is primarily due to the solder mask applied during the manufacturing process. The solder mask is a protective layer that prevents solder bridges from forming between closely spaced solder pads. While PCBs can come in various colors, green is the most commonly used. This choice is not merely aesthetic but has several practical reasons.

Historical and Functional Reasons

Green was chosen historically because it provided the best contrast with white silkscreen printing, allowing easy inspection of the board. This color also helps technicians and automated optical inspection systems detect defects and errors more effectively.

Cost-Effectiveness

Green solder masks have been around for decades, making them more cost-effective due to their widespread use. The production processes for green masks are well-established, which reduces costs compared to less commonly used colors like red or blue.

The Advantages of Green PCB Boards

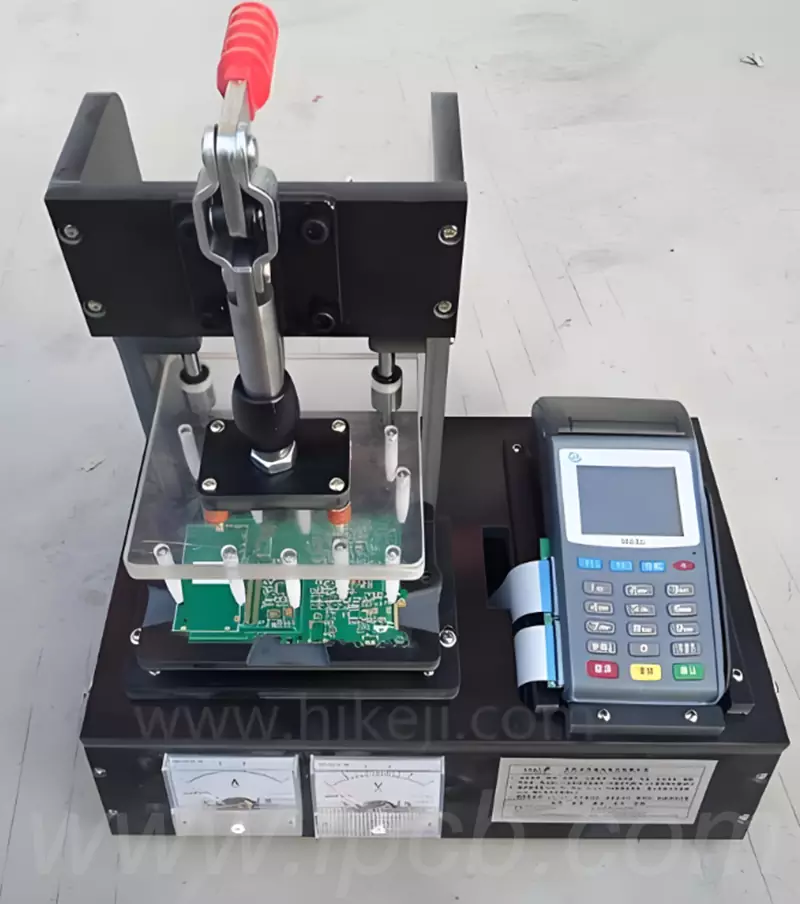

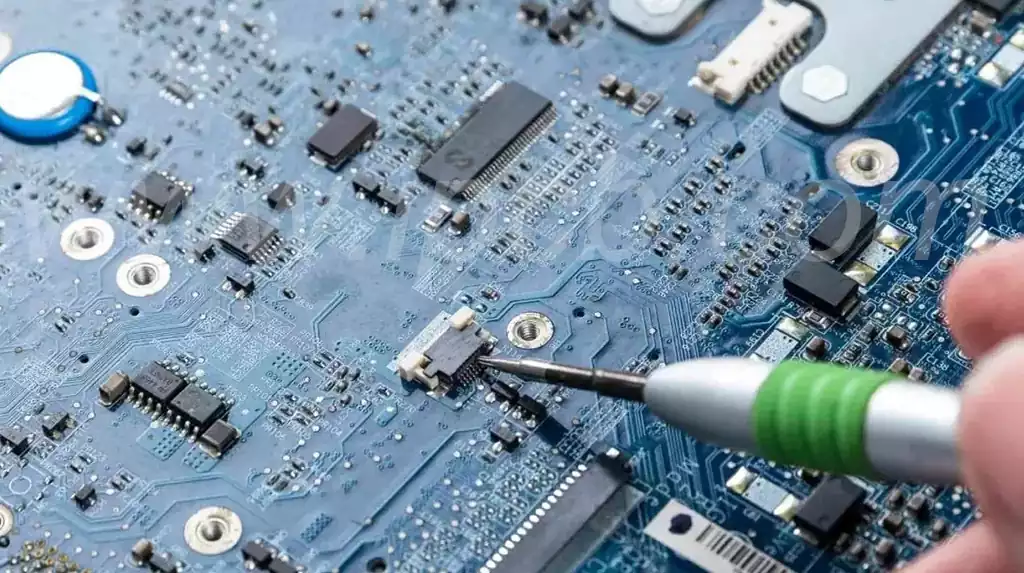

Enhanced Visibility and Inspection

Green PCB boards provide excellent contrast for the white silkscreen layer, which includes component labels and instructions. This contrast enhances visibility, making it easier for technicians and engineers to inspect the boards during assembly and repair.

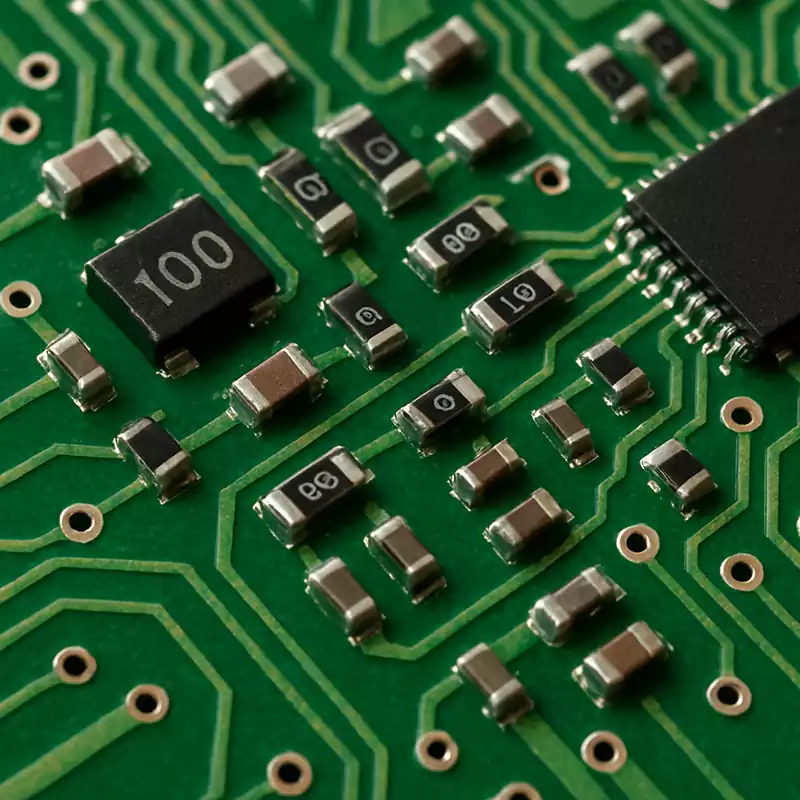

Improved Solderability

The green solder mask is known for its superior solderability. It ensures that solder does not spread to unwanted areas, reducing the risk of short circuits and enhancing the reliability of the connections. This property is crucial for maintaining the integrity of electronic devices, especially in complex circuits.

Thermal Stability

Green PCB boards are often made with materials that have good thermal stability. This means they can withstand the high temperatures encountered during soldering processes without degrading. This stability ensures that the PCBs maintain their performance and longevity, even in demanding applications.

Environmental Considerations

The term “green” in green PCB boards isn’t just about color; it also represents environmentally friendly manufacturing processes. Many manufacturers are now focused on producing PCBs that are RoHS (Restriction of Hazardous Substances) compliant. This compliance means that the boards are free from harmful substances like lead and cadmium, making them safer for both the environment and human health.

Versatility in Applications

Green PCB boards are versatile and can be used in a wide range of electronic applications. From consumer electronics to industrial machinery, the benefits of durability, reliability, and cost-effectiveness make green PCBs a preferred choice for manufacturers across various industries.

Green Electronics and Sustainability

The electronics industry is increasingly prioritizing sustainability, and green PCB boards play a significant role in this movement. By opting for environmentally friendly practices, companies contribute to a greener planet while also meeting the growing consumer demand for sustainable products.

Reduced Environmental Impact

Manufacturing processes for green PCB boards often include measures to minimize waste and energy consumption. This reduction in resource usage contributes to a lower environmental footprint, aligning with global efforts to combat climate change and reduce pollution.

Recyclability

Many green PCB boards are designed with recyclability in mind. At the end of their lifecycle, these boards can be recycled to recover valuable materials like copper and gold, reducing the need for new raw materials and minimizing electronic waste.

Challenges and Considerations

While there are numerous benefits to using green PCB boards, there are also challenges and considerations that manufacturers must address.

Material Availability

The demand for eco-friendly materials can sometimes lead to supply chain challenges. Ensuring a consistent supply of high-quality, RoHS-compliant materials is essential for maintaining production schedules and meeting consumer expectations.

Balancing Cost and Quality

While green PCB boards are generally cost-effective, manufacturers must balance cost savings with quality assurance. Cutting corners to reduce expenses can lead to issues with reliability and performance, ultimately impacting customer satisfaction.

The benefits of using green PCB boards extend beyond their iconic color. Their cost-effectiveness, environmental friendliness, and superior performance make them a staple in the electronics industry. As the world moves towards more sustainable practices, green PCB boards will continue to play a crucial role in achieving environmental goals while delivering reliable and high-quality electronic products.