The pcb board power supply line is the main way for electromagnetic interference to enter and exit the circuit. Printed circuit board through the power line, the outside world of interference may enter the internal circuit, affecting the performance of the RF circuit. In order to reduce electromagnetic radiation and coupling, DC-DC module side, secondary side and load side loop area, no matter how complex the form of the power supply circuit, high-current circuit should be as small as possible, the power supply and grounding cables should always be placed closely together.

If a switching pcb board power supply is used in the circuit, the layout of the switching power supply peripherals should conform to the principle of short return paths for each power supply. Filter capacitors should be close to the relevant pins of the switching power supply and common mode inductors close to the switching power supply module.

Patches on long distance power cords should not be close to or simultaneously near the outputs and inputs through cascade amplifiers (gain greater than 45db) to avoid the power cord becoming a transmission conduit for RF signals, which could result in self-excitation or low sector isolation. Long power lines need to carry high-frequency filter capacitors at both ends, even in the mid- to high-frequency filter capacitors.

The power inlet of the RF PCB consists of a combination of 3 parallel filter capacitors which are used to filter low, medium and high frequencies on the power line, such as 10uF, 0.1uF and 100PF, which are located close to the input pins of the power supply in descending order.

If the same set of power supplies is used to power a small-signal cascade amplifier, the power supplies should be supplied to the preceding stages in order, starting with the last stage, so that EMI generated by the circuitry in the last stage will have less effect on the preceding stages. Each power supply filter has at least two capacitors: 0.1uF and 100pF. When the signal frequency is higher than 1GHz, a new 10pF filter capacitor should be added.

Filter capacitors commonly used in low-power electronic filters are close to the triode legs and closer to the pin high-frequency filter capacitors. The triode selects a lower cutoff frequency. If both are high-frequency tubes, triode electronic filter work in the community, the layout of peripheral devices is not reasonable, the output power is prone to high-frequency oscillation.

The linear voltage regulator module may also have the same problem because there is a response loop in the chip, the internal triode works in the amplification region, and the layout process requires high-frequency filter capacitors to be close to the pins to minimize the distributed inductance and disrupt the oscillation conditions.

The copper foil size in the power section of the PCB is sized for the current flowing through it, with allowances taken into account (typically 1A/mm line width as a reference).

PCB board power supply cable inputs and outputs must not be crossed.

Pay attention to power decoupling and filtering to prevent interference from different units through the power lines. Power lines should be isolated from each other and from other strong interference lines (e.g. CLK).

The wiring of the small signal amplifier power supply needs to be isolated by grounding copper foil and grounding holes to avoid the intrusion of other EMI interference and deterioration of signal quality.

Overlapping of different power supply planes should be avoided spatially, mainly to minimize interference between different power supplies, especially between some power supplies with very different voltages. The problem of overlapping power supply planes must be avoided.

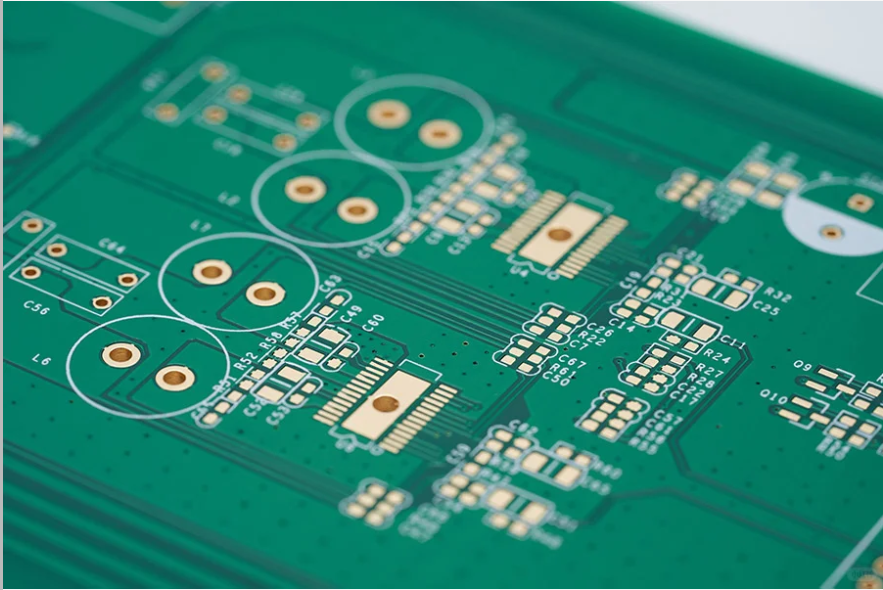

PCB layer assignment helps in the subsequent wiring process. For a four-layer PCB (typically used for WLANs), in most applications, components and RF leads are placed on the top layer of the PCB substrate, the second layer is systematically placed on layer 3, and any signal lines can be distributed on the fourth layer.

The second layer is laid out in a continuous ground plane because it is necessary to establish an impedance-controlled RF signal path, and it is also easy to achieve the shortest possible loops, providing a high degree of electrical isolation between the layer and layer 3, which allows coupling between the two layers. Of course, other board layer definitions can be used, especially in boards with different layers, but the above structure has proven to be successful.

The power of large Vcc wiring layers can be easily realized, however, this structure is often a prelude to deteriorating system performance. Putting all the power fuses together on a larger plane will not prevent noise transfer between pins. On the other hand, coupling between different power pins can be reduced if a star topology is used.

Good pcb board power supply decoupling techniques and accurate PCB layout provide a solid foundation for the design of any RF system. While there are other factors that degrade system performance in real-world designs, having a “noise-free” power supply is critical to optimizing system performance.