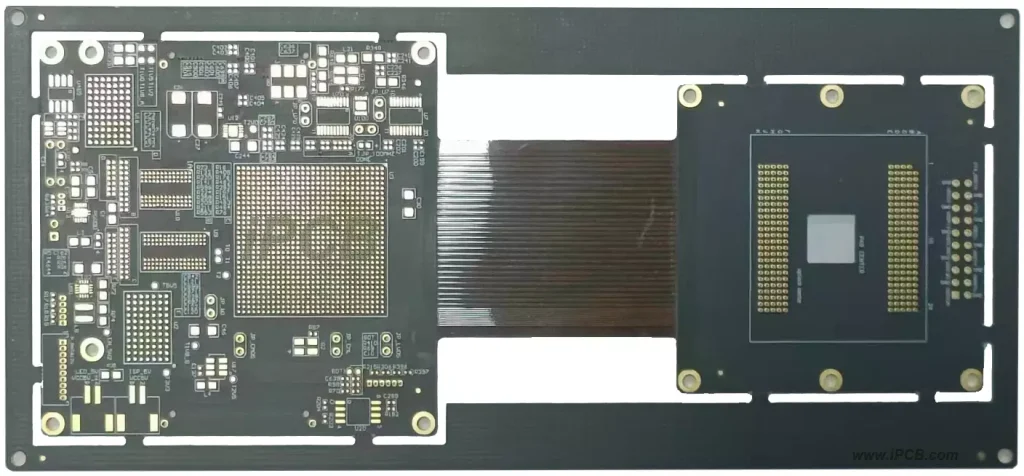

What is a FPC? FPC is short for Flexible Printed Circuit, which is called Flexible Printed Circuit Board in Chinese. It is a kind of printed circuit board made of polyimide or polyester film as the base material, with high reliability and excellent flexibility. Its main advantages include the ability to be freely bent, rolled and folded, small size, thin thickness and light weight, which improves the space utilization and flexibility of electronic products. In addition, FPC has good heat dissipation and solderability, as well as easy assembly and lower overall cost.FPC is widely used in communication equipment, consumer electronics, aerospace, military, mobile communications, laptop computers, computer peripherals, PDAs, digital cameras and other fields.

FPC basic structure material introduction

From the analysis of the basic structure of the flexible printed circuit board, the materials that constitute the flexible printed circuit board are insulating substrate, adhesive, metal conductor layer (copper foil) and cover layer .

01.Copper Film

Copper foil is basically divided into electrolytic copper and calendered copper. The common thicknesses are 1oz 1/2oz and 1/3 oz.

Substrate Film: The common thicknesses are 1 mil and 1/2 mil.

Adhesive: Thickness depends on your needs.

02.Cover Film

Cover Film: For surface insulation. Common thicknesses are 1 mil and 1/2 mil.

Adhesive: Thickness depends on your needs.

Release paper: To avoid adhesive from sticking to foreign objects before pressing; to facilitate the work.

- Reinforcement Plate (PI STIffener Film)

PI STIffener Film: reinforces the mechanical strength of the FPC and facilitates the surface mounting operation. The common thickness is 3 mil to 9 mil.

Adhesive: Thickness depends on your needs.

Release paper: to avoid adhesive adhesive in the pressure before the attachment of foreign objects.

EMI: Electromagnetic shielding film, to protect the circuit board lines from outside (strong electromagnetic area or susceptible to interference) interference.

The core of FPC design lies in connecting electronic components, connectors, sensors and other assemblies together in an optimized way, while ensuring the stability and reliability of the circuit. This design process requires engineers with in-depth knowledge of electronics, superb design skills and extensive practical experience. Designers need to carefully consider the layout of the circuit, the direction of the wires, the arrangement of components and other factors to ensure that the FPC meets the performance requirements while minimizing size and weight.

The choice of materials is also crucial in the FPC design process. Flexible materials have good bending, crease resistance and high temperature resistance, making the FPC adaptable to a variety of complex application scenarios. In addition, conductive materials, insulating materials and protective materials also need to be carefully selected according to specific needs to ensure the performance and stability of the circuit.