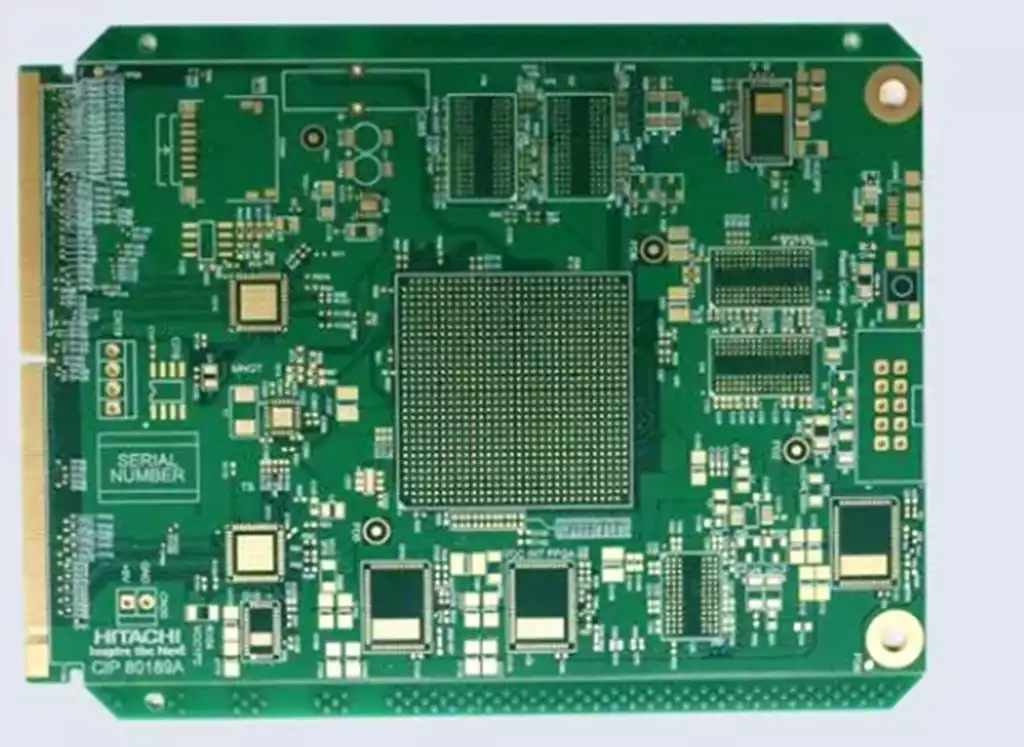

What is pcb copy board?PCB copy board is a technical means, through the other people’s PCB samples for measurement, analysis and imitation, to complete the original product replication and improvement.It is widely used in the development and production of electronic equipment.PCB copy board is divided into hardware copy board and software copy board. It is widely used in the research and development and production of electronic equipment.PCB copy board is divided into two categories: hardware copy board and software copy board. Hardware copy board is mainly through the analysis of PCB drawings and boards, the use of the same or similar materials and processes, copying the original product with similar or even better PCB boards. The software copy board is through the original product circuit and program analysis and imitation, to achieve the same or similar function.

How to copy a pcb board

- Get the sample board: first of all, you need to get the sample board to be copied, you can use photos, scanning or directly buy samples and other ways to get the board data.

- Data extraction and processing: the circuit board data extraction and processing, including the size of the board, component layout, alignment and other information. This step can use professional software for automated processing, but also manual measurement and labeling.

- Design circuit boards: According to the extracted and processed data, start designing the circuit board. This step needs to take into account the layout of the circuit board, wiring, component selection and other factors to ensure that the function and performance of the circuit board meet the requirements.

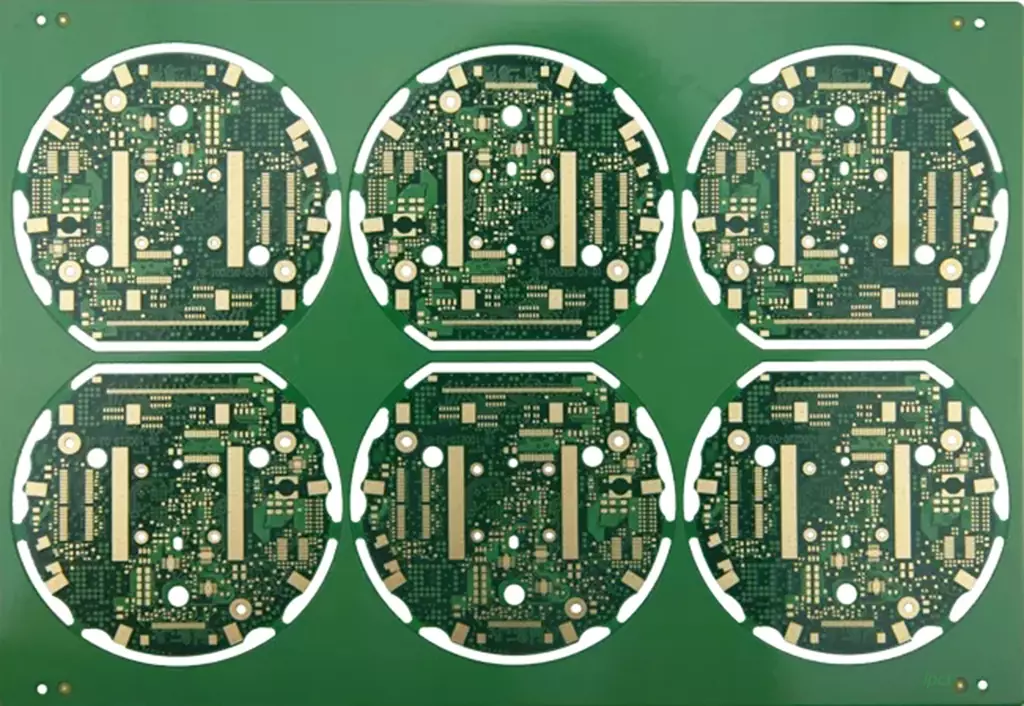

- Produce the circuit board: According to the designed circuit board diagram, produce the actual printed circuit board. This step can use laser cutting, mechanical drilling and other ways to make.

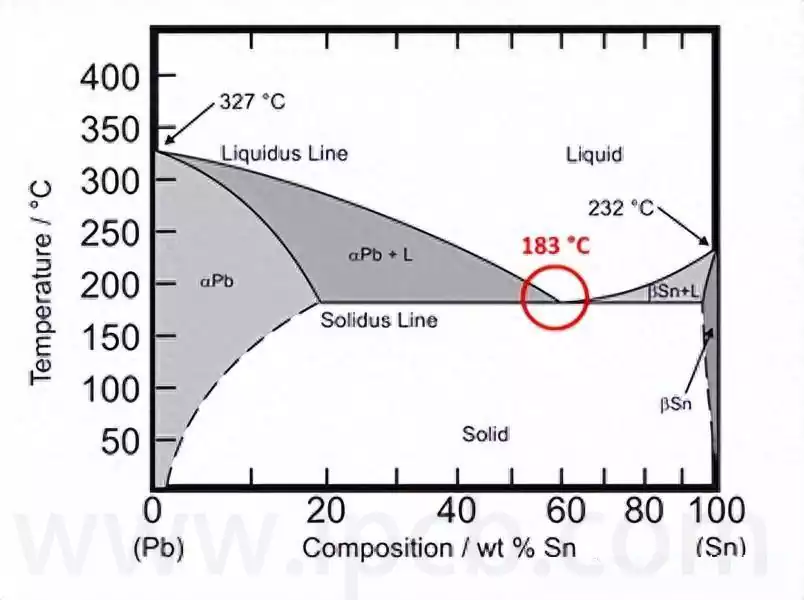

- Soldering components: Solder the required components to the circuit board to ensure that the function and performance of the circuit board is realized. This step needs to ensure the quality of welding to avoid problems such as false welding and short circuit.

- Testing and debugging: test and debug the circuit board to ensure that its function and performance meet the requirements. This step requires detailed testing and debugging of all parts of the circuit board to ensure the reliability and stability of the circuit board.

Circuit board cloning is a relatively cumbersome process, which needs to involve a number of links and steps. Therefore, when conducting PCB copy board, you need to consider the details of each link and ensure the quality and reliability of each link.

Application areas of PCB board copy?

PCB copy board technology has a wide range of applications in several fields. Firstly, in the repair and refurbishment of electronic products, PCB copy board technology can help repairers to quickly copy damaged pcb boards and restore the normal function of the equipment. Secondly, in the imitation and improvement of electronic products, board copying technology is also an indispensable tool. Through in-depth analysis and improved design of the original circuit board, new products with better performance and more comprehensive functions can be produced. In addition,it also plays an important role in teaching, scientific research and other fields, providing strong support for the inheritance and innovation of electronic technology.

Benefits of circuit board cloning

- Acceleration of product development: In the product development stage, copy board technology can greatly shorten the development cycle. By copying the circuit boards of existing products on the market, enterprises can quickly understand the product design and technical level of competitors, so as to provide reference for their new product development.

- Reduction of maintenance costs: For some circuit boards that have been discontinued or are difficult to purchase, copy board technology can be used as an effective alternative. By copying the board, the enterprise can make the board independently, reduce the maintenance cost and avoid the equipment downtime caused by the board problem.

- Technical learning opportunities:The board copying process is actually a reverse learning process. By copying the circuit boards, engineers can gain a deeper understanding of the circuit board design principles, wiring techniques, component selection and other key technologies, which is of positive significance to enhance the technical level of engineers.

- Customized solutions: In some specific scenarios, customers may need customized circuit boards to meet their special needs. PCB copy board technology can provide such customers with fast and accurate customized solutions to help customers achieve product differentiation and competition.

As a key technology in the field of electronics, circuit board cloning not only provides strong support for product development, repair and imitation, but also injects new vitality into the inheritance and innovation of electronic technology.