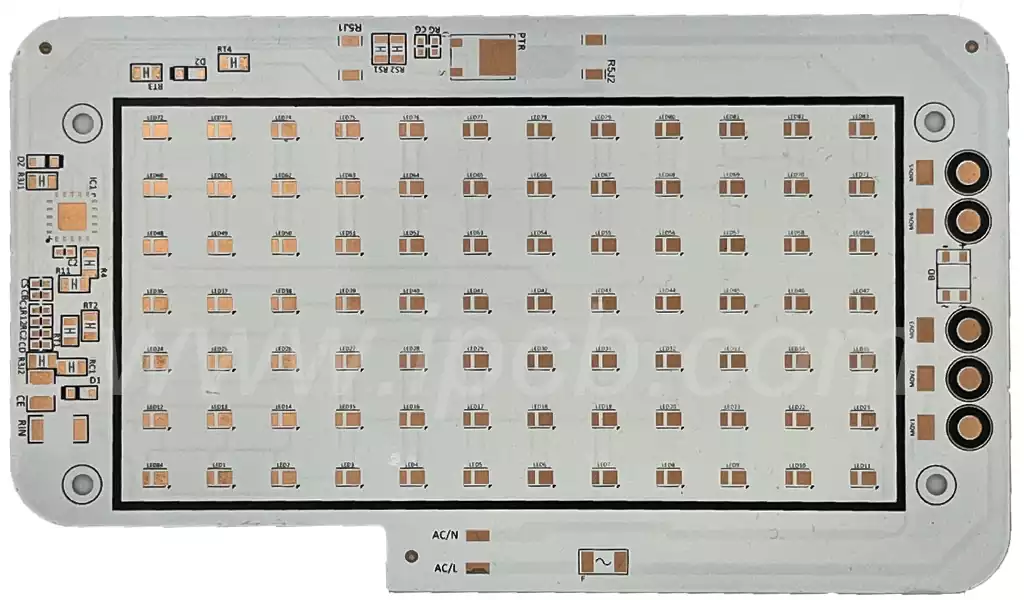

Flexible aluminum pcb refers to the aluminum as the substrate, through a variety of ways to enhance the flexibility of the material of a material. The addition of other elements, the modulation of the organizational structure and the treatment of the surface can improve the flexibility of the aluminum substrate without affecting its thermal conductivity and mechanical properties.

One of the latest developments in IMS materials is flexible dielectrics. These materials provide excellent electrical insulation, flexibility and thermal conductivity. When applied to flexible aluminum materials, products can be formed to achieve a variety of shapes and angles, which can eliminate expensive fixtures, cables and connectors.

Currently, the main material standards for flexible aluminum substrates are as follows:

- Single-layer Aluminum flex pcb

It is a single-layer sheet with a thickness between 0.02mm~0.2mm made by plating and cutting aluminum substrate during processing. The material has good thermal conductivity and mechanical properties, but relatively poor flexibility. - Double-layer flexible aluminum pcb

It refers to the single-layer flexible aluminum substrate on the basis of adding composite materials, films and other structures to strengthen the flexibility, so as to obtain better mechanical properties and flexibility.

3.Multi-layer flexible aluminum pcb

It refers to the double-layer flexible aluminum substrate based on the further addition of functional materials and surface treatment agents, to achieve higher thermal conductivity, mechanical properties and flexibility.

Flexible Aluminum pcb vs Other Aluminum Substrates

1.Material structure and flexibility

Aluminum flex pcb is made of flexible materials, such as polyimide (PI) and other flexible substrates, combined with an aluminum layer (may be aluminum foil or aluminized layer) to form. Its best feature is its ability to be bent, folded, or even curled to accommodate a variety of complex shapes and angles. Other aluminum substrates usually use a rigid substrate (e.g., FR-4, ceramic, or metal plate) as a support, and the aluminum layer is bonded to the substrate through bonding or plating. They do not have the flexibility and bendability of flexible aluminum substrates, and are usually used in applications that require high rigidity and stability.

2.Performance Characteristics

In addition to excellent electrical insulation, flexible aluminum pcb is also easy to install and maintain due to their flexibility, eliminating the need to rely on expensive fixtures, cables and connectors and reducing system complexity and cost. At the same time, the presence of an aluminum layer gives it good thermal conductivity, which helps dissipate heat.

Hybrid aluminum substrates combine the electrical performance of traditional FR-4 substrates with the heat dissipation benefits of an aluminum base, improving overall thermal management efficiency and structural rigidity. At the same time, the aluminum substrate also serves as an electromagnetic shielding layer to reduce electromagnetic interference.

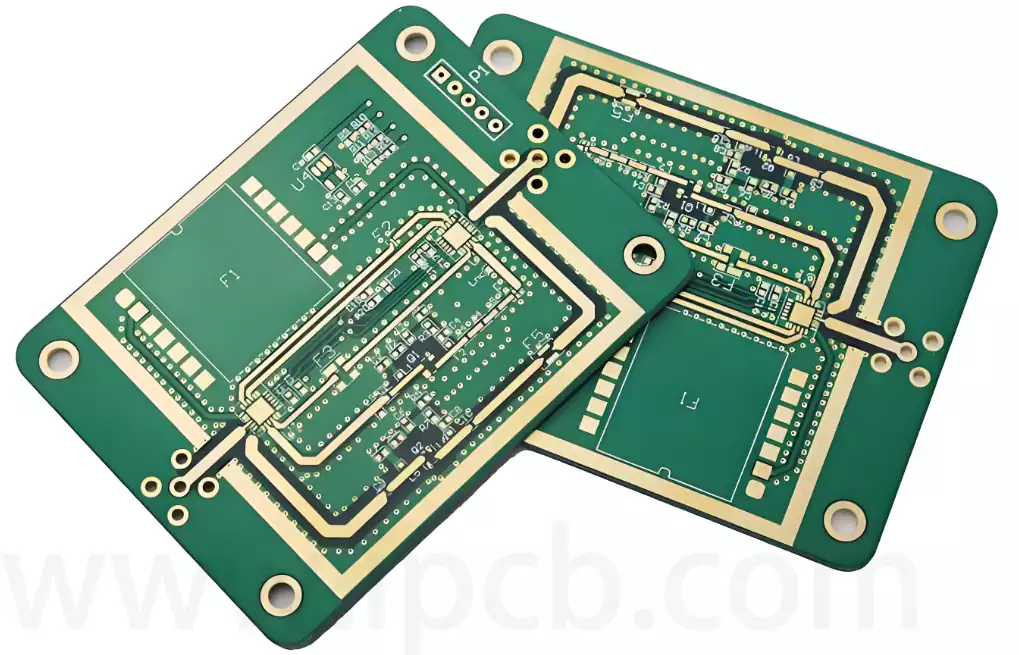

Multi-layer aluminum substrates achieve higher integration and more complex circuit layouts through multi-layer structural design. Blind hole technology allows for more flexible interlayer connections while maintaining good thermal conductivity.

Through-hole aluminum substrates form through-holes in the aluminum layers by plating and filling dielectrics, ensuring electrical insulation while enabling electrical connections between layers. This structure is particularly suitable for applications requiring high reliability and high density connections.

3.Application Scenarios

Aluminum flex pcb is widely used in wearable devices, flexible displays, flexible solar panels, medical electronics, aerospace and other fields, with high requirements for thinness, portability and flexibility.

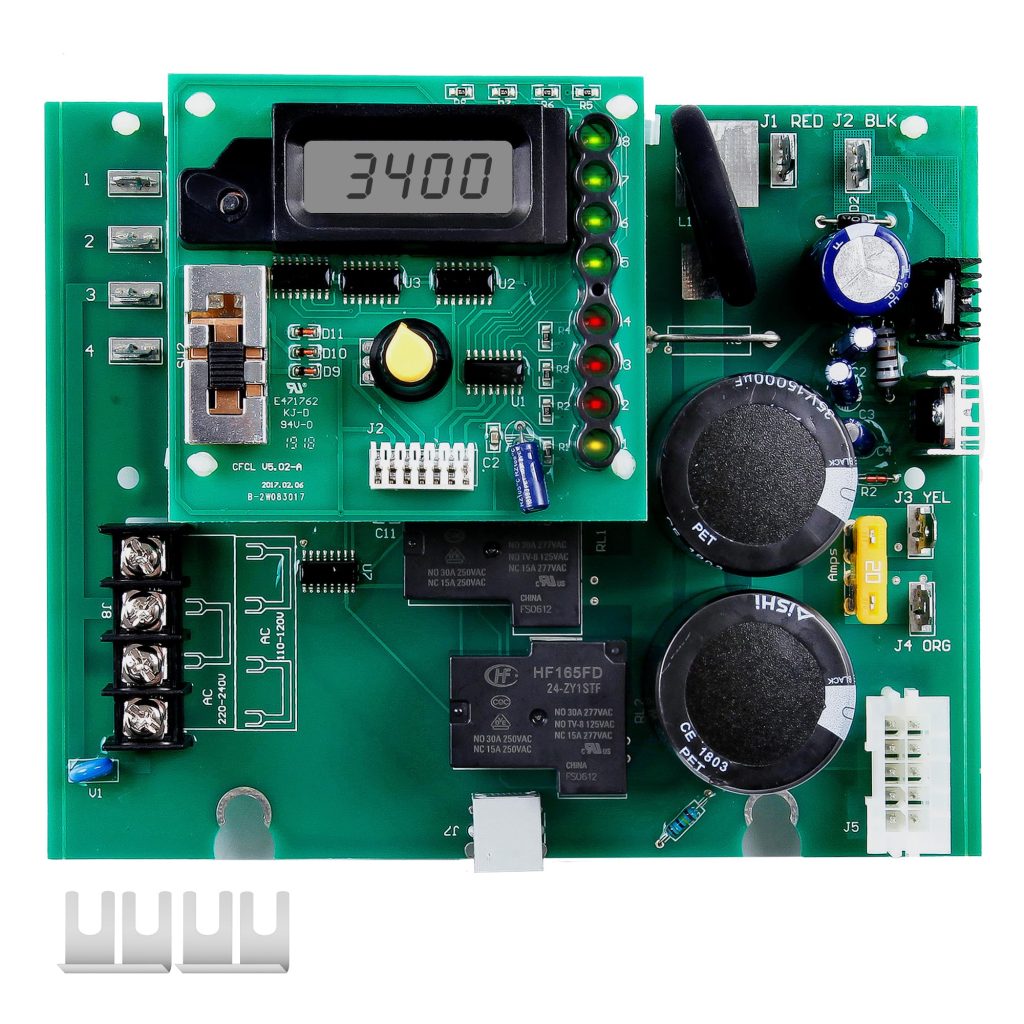

Other aluminum substrates are more often used in applications with higher heat dissipation requirements, greater structural rigidity, and higher circuit complexity, such as LED lighting, automotive electronics, communication equipment, industrial control and other fields.

- Manufacturing process

Aluminum flex pcb manufacturing process is relatively complex, requiring special flexible substrate processing technology and precision lamination technology to ensure the flexibility of the substrate and the stability of electrical performance.

Others rely more on traditional PCB manufacturing processes, such as etching, plating, lamination, etc., but the treatment of the aluminum layer may require special process steps, such as plating, bonding and so on.

As a new type of material, flexible aluminum pcb has a broad application prospect in the field of electronics. Mainly used in the following areas:

1.LED lighting field

Because of its high thermal conductivity and flexibility, it has become an important material in the field of LED lighting, which can optimize the contact between the LED luminous body and the heat sink and heat insulator, and improve the heat dissipation efficiency of LED.

- Electronic heat dissipation field

Because of its high thermal conductivity, and combined with the excellent performance of flexible materials, it is widely used in the field of electronic heat dissipation. Flexible aluminum substrates can be used to make heat sinks, heat sinks, heat sinks and other heat dissipation parts, which can effectively dissipate heat in high temperature environments. - High-speed communication field

High thermal conductivity and mechanical properties, in the field of high-speed communications to achieve its important applications. Since high-speed communication equipment generates a lot of heat during the working process, Aluminum flex pcb can be used to make heat sinks and circuit boards for high-speed communication systems to ensure that the equipment works stably at high temperatures. - Electronic technology field

High processability, so it is also widely used in the field of electronic technology. For example, adjustable inductors, filters, opto-couplers, etc., can be made using flexible aluminum substrate as a substrate.

Flexible aluminum pcb, as an innovative material in the field of electronics, is with its unique flexibility and excellent performance, continue to broaden the application boundaries, leading the electronic technology to new heights.