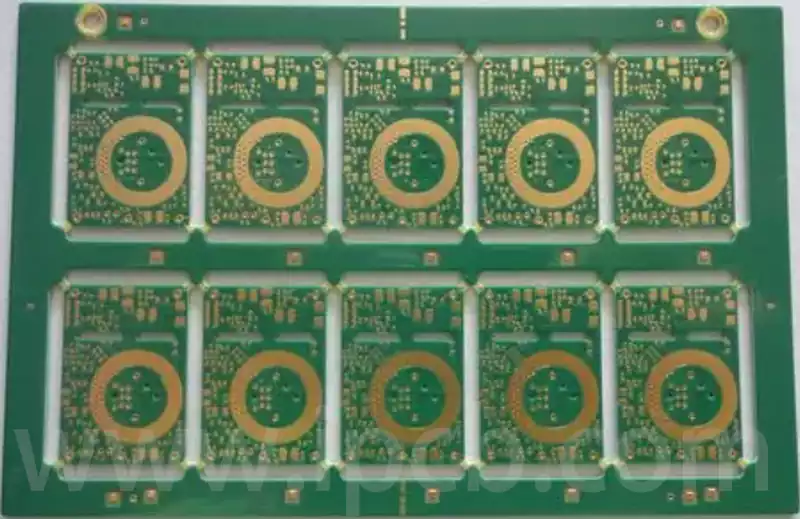

The battery charger pcb board is a kind of intelligent protection electronic circuit, which can protect the battery in many ways, not only to prevent the battery from overcharging and over-discharging, but also to protect the battery from being damaged by over-current, over-voltage, short-circuit and other problems. During the battery charging process, the internal voltage of the battery rises continuously, and when the battery is fully charged, the charging circuit board automatically cuts off the charging to prevent overcharging, thus prolonging the service life of the battery. If the battery is never protected, it will not only shorten the life of the battery, but may also cause the battery to explode during charging.

Common battery charger pcb board types and characteristics

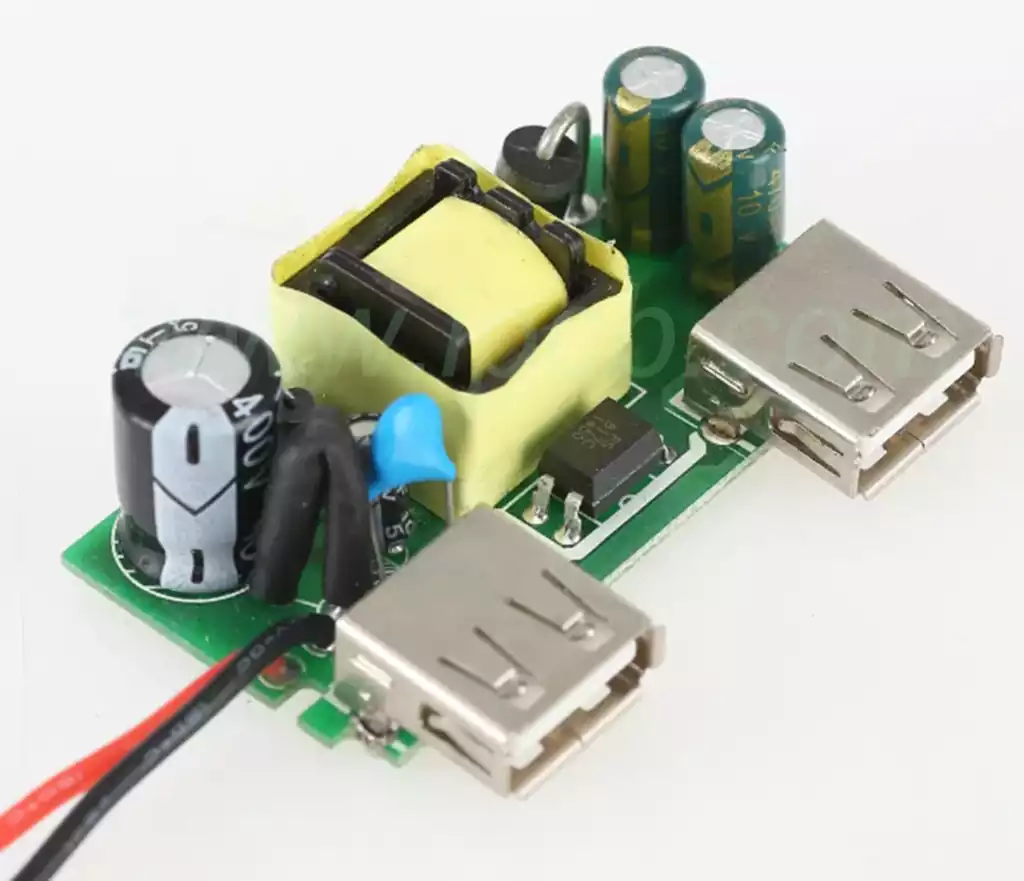

Ordinary charger circuit boards: This kind of circuit board is the most common charger circuit board for all ordinary chargers, with slower charging speeds, usually only able to provide 5V/1A charging current for the device, and unable to charge quickly. This kind of circuit board is inexpensive and has a low manufacturing cost.

Rapid battery charger pcb board: This kind of printed circuit board supports various fast charging protocols, which can realize rapid charging, and the charging speed is more than 2 times faster than the normal charger speed. However, this circuit board is more expensive to manufacture, and the price is usually more expensive.

Wireless charger circuit boards: These circuit boards support wireless charging technology and can provide charging current for wireless charging devices. Compared to wired chargers, wireless chargers are more convenient to use, but the charging speed is slower.

USB-C charger circuit board: this circuit board supports the latest USB-C interface, can provide a maximum of 100W charging power for USB-C devices, support fast charging. However, this circuit board is more expensive and suitable for users who need high quality fast charging effect.

The charger circuit board is used to control the current and voltage so that the battery can be charged quickly. However, circuit boards can also be used in other areas. Some of the other uses of charger circuit boards are as follows.

Smart Home Controller

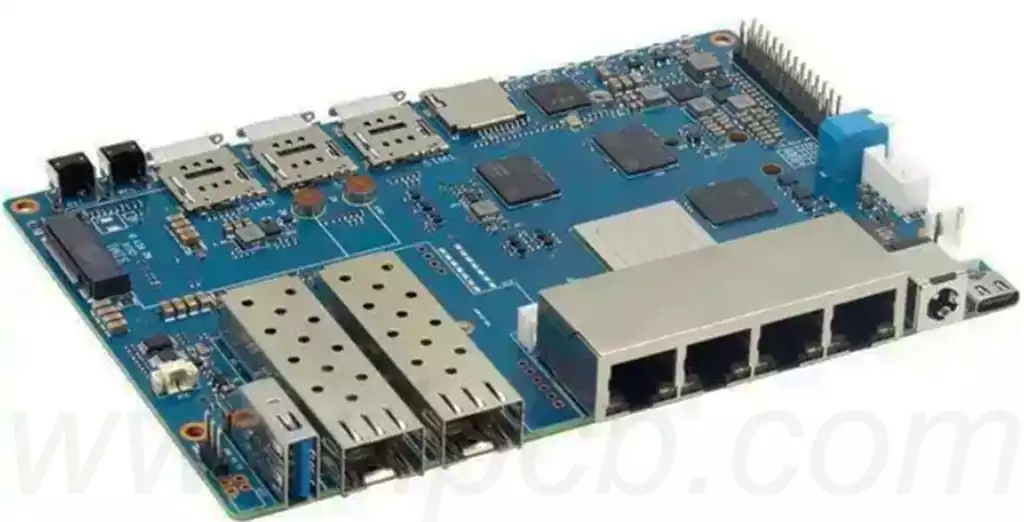

Smart homes have become a hot topic in today’s society. By controlling sensors and actuators, automated control of home devices can be realized. Smart home controllers generally need to control a variety of devices and require a circuit board that integrates multiple ports as well as data collection and processing.

The design of a charger circuit board is somewhat similar to that of a smart home controller, as both require the integration of multiple functional modules. As a result, some manufacturers convert charger pcb boards into smart home controllers for marketing purposes.

Gamepad

With the development of the gaming industry, more and more gamers are purchasing gamepads to enhance their gaming experience. Gamepads generally require the integration of multiple buttons and joysticks, and these components need to be controlled through the circuit board.

There are also similarities between charger circuit boards and gamepad circuit boards. Since both require the integration of multiple buttons and control terminals, manufacturers can convert charger circuit boards into gamepad circuit boards.

Drones

Drones are a fast-growing segment of the aerospace industry and their demand has been increasing day by day in recent years. Drones are connected with several functional modules such as communication module, control module, video module, and positioning module, to name a few. These modules need to be integrated together through circuit boards.

The design of the battery charger pcb board is similar to that of a drone, so some marketers are converting charger circuit boards to drone circuit boards. This modification eliminates some of the design costs and also greatly improves the productivity of the drone.

Choosing a charger circuit board requires consideration of several factors, such as applicable equipment, charging speed, safety and cost. Different kinds of chargers require the selection of different kinds of circuit boards, for example, fast chargers require the use of circuit boards that support the fast charging protocol, and USB-C chargers require the selection of circuit boards that comply with the USB-C standard.

When choosing a battery charger pcb board, you also need to take into account the actual size of the PCB and wiring rigor, to ensure that the size of the circuit board is suitable for the development of the charger’s shell and internal space, and to ensure that the PCB wiring rigor to ensure the long-term stability and safety of the charger.

Battery charger pcb board, as a bridge between battery protection and application innovation, are leading the development of intelligent technology in the direction of safer and more efficient, bringing infinite possibilities for our lives.