PCB connector is a key component used in electronic equipment to achieve circuit connection and signal transmission, plays a key role in connecting circuit boards and external devices, and achieving signal and current transmission. In modern electronic products, the design and selection of connectors are critical to the performance, stability and reliability of the entire device.

The working principle of PCB connector is based on the realisation of mechanical and electrical connections. The connector realises the electrical connection between electronic devices by means of contacts. There are various forms of contact of the contacts, such as pinhole contact, sheet contact, wire contact and so on. Once the contact between the contacts has been realised, current can be transmitted through the contacts. The conductivity of the contact depends on factors such as its material, shape and size.

Types of PCB connectors

1.Power Connector

Power connectors are connectors used to connect power signals. Depending on the use, power connectors can be broadly divided into AC power connectors and DC power connectors. AC power connectors are mainly used in power outlets, UPS power supplies and generator equipment,while DC power connectors are used in solar energy systems, lithium battery equipment and power supply to the circuit board and other fields.Common power connectors are XLR, JST, Lemo and so on.

2.Signal connectors

Signal connector is used to connect the signal signal connector,widely used in audio equipment, video equipment, communication equipment, television sets, automotive electronic equipment. Signal connectors can be divided into plug-type connectors and socket-type connectors according to the different connection methods.Plug-type connectors are connected to the outside of the device,while socket-type connectors are connected to the inside of the device and are mainly used for transmitting audio,TV signals,video signals and so on.Common signal connectors are RCA,F-type,BNC,D-SUB and so on.

3.Data Connector

Data connector is a connector dedicated to connecting data lines.Nowadays,data connectors are used in a wide range of applications, including computers, network communication equipment, instrumentation, mobile phones, digital cameras, etc..Data connectors are used to connect and transmit digital signals, it is a high-precision, high-speed transmission of data electronic components. Common data connectors are USB, RJ45, HDMI and DVI.

Main application areas of PCB connector:

1.Communication network infrastructure: PCB connector plays a vital role in communication equipment, such as routers, switches and fibre optic equipment. They ensure the stable transmission of signals and the efficient operation of equipment.

2.Consumer electronics: PCB connector is used to connect internal components such as displays, cameras and batteries in devices such as smartphones, tablets, TVs and stereos.

3.Computer equipment: PCB connector plays a role in connecting components such as computer motherboards, graphics cards and hard disc controllers to ensure the accuracy and speed of data transmission.

4.Medical equipment: PCB connectors are used in medical equipment such as electrocardiographs, sphygmomanometers and medical monitoring equipment to ensure accurate transmission of medical data and reliability of the equipment.

5.Industrial control equipment: In industrial automation and control systems, such as PLC (Programmable Logic Controller), they are used to connect sensors, actuators and control units to achieve precise control.

6.Automotive electronics: Automotive connectors are widely used in power systems, body systems, information control systems, safety systems and in-vehicle equipment. With the development of automotive electrification and intelligent network connection, the demand for high-voltage connectors and high-speed connectors is increasing.

7.Military and aerospace: In the military and aerospace fields, PCB connectors are used to connect complex electronic systems to ensure reliability and stability in extreme environments.

8.Servers and Data Centres: As the demand for AI servers grows, they for servers play a key role in data transmission and processing, supporting high-speed data exchange and storage.

9.Wearable devices: they are used to connect sensors and displays in wearable devices such as smartwatches,health monitoring bands, etc. to achieve real-time data transmission and display.

10.Household appliances: In household appliances such as microwave ovens,washing machines and air conditioners, they are used to connect control boards and motors to ensure stable operation of the equipment.

A PCB connector kit is a collection of components used to create electrical connections on a printed circuit board. These kits usually include different types of connecting components such as jumpers, crimp terminals and sometimes PCB housings. They are widely used to test different circuit configurations to meet user requirements.

Common types of PCB connector kits:

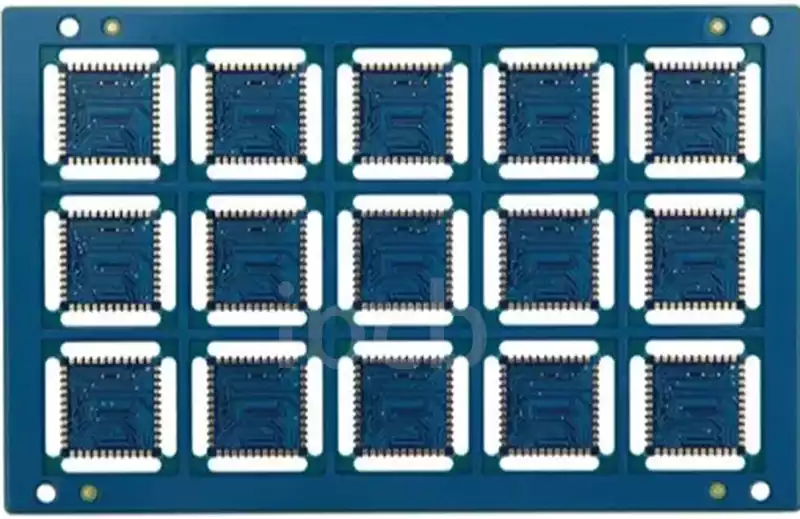

1.Through-Hole Connectors: These connectors are inserted through a hole in the board and secured on the other side. They are typically used in applications requiring mechanical strength and electrical stability.

2.Surface Mount Connectors (Surface-Mount Connectors): Unlike straight connectors, surface mount connectors are mounted directly to the surface of the PCB without passing through holes. They are suitable for space-constrained and miniaturised designs.

3.Box Connectors: This type of connector is usually used for power and signal inputs and outputs, with good shielding performance, suitable for applications requiring electromagnetic compatibility (EMC).

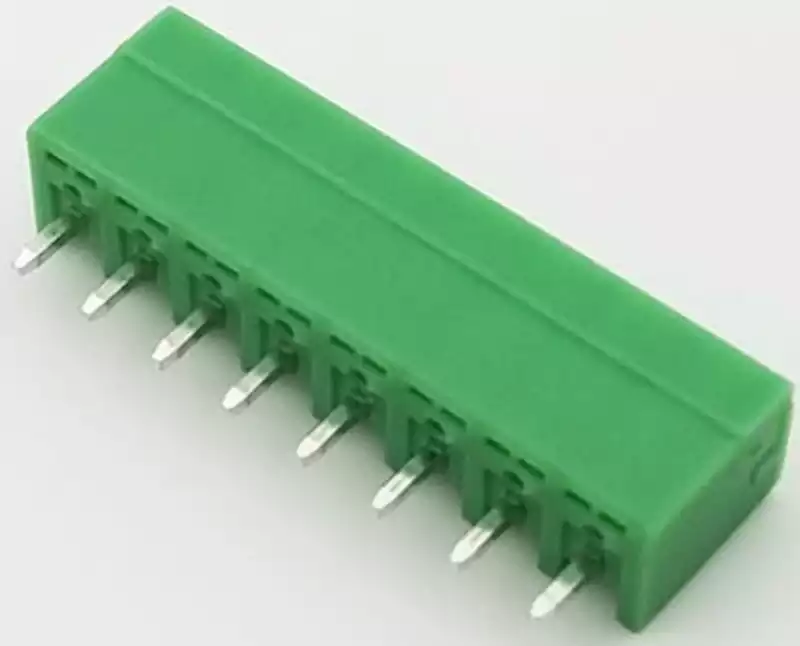

4.Socket connectors (Socket Connectors): socket connectors are used for pluggable components such as integrated circuits (ICs) and microprocessors. They allow the user to replace or upgrade components without replacing the entire circuit board.

5.Flat Cable Connectors: These connectors are designed to connect flat cables and are commonly used in portable devices and flexible circuit boards. 6.

6.Circular Connectors: Circular connectors have multiple contact points and are commonly used in military and aerospace applications because of their ability to withstand harsh environmental conditions.

7.Radio Frequency Connectors (RF Connectors): RF connectors are specifically designed to transmit high frequency signals, such as radio frequencies. They need to have good shielding and low signal loss characteristics.

8.High-Speed Signal Connectors (High-Speed Signal Connectors): These connectors are designed for high-speed data transmission, such as USB, HDMI and SATA interfaces. They need to have low insertion loss and good signal integrity.

9.Power Connectors (Power Connectors): Power connectors are used to transmit power, they need to be able to withstand high currents and voltages, while maintaining low resistance and good thermal performance.

10.Custom connectors (Custom Connectors): according to the needs of specific applications, custom connectors can be designed and manufactured to meet specific electrical, mechanical and environmental requirements.

How to choose the right pcb connector kits:

1.Determine the connection needs:first of all,you need to define the purpose of the connector,such as whether it is used for board-to-board connection,board-to-wire connection or other purposes.This will affect the type and specification of connector you choose.

2.Consider electrical performance:According to the circuit design, consider the current carrying capacity,voltage level and signal transmission characteristics of the connector.For example,high-speed signal transmission may require low impedance and good shielding performance.

3.Mechanical properties:the mechanical properties of the connector,such as temperature and humidity resistance,is also very important. Ensure that the selected connector can adapt to the expected operating environment.

4.Physical size and shape:The size and shape of the connector should match the PCB layout and space constraints.For example,compact applications may require smaller connectors.

5.Dummy-proof design:Selecting connectors with dummy-proof features can reduce assembly errors.Make sure the connector is designed to prevent incorrect insertion.

6.Compatibility:Consider the compatibility of the connector with other components, including compatibility with other connectors.Ensure that the selected connector can be compatible with existing systems or standards.

7.Cost-effectiveness:While meeting the technical requirements, consider the cost of the connector.Selecting cost-effective connectors can reduce overall project costs.

8.Supplier and brand:Selecting reputable suppliers and brands can ensure the quality and reliability of the connector.Well-known brands such as Molex, TE Connectivity, etc.usually provide more extensive support and better after-sales service.

9.Certification and standards:Ensure that the selected connector meets the relevant industry standards and certification requirements,such as UL certification, CE marking and so on.

10.Testing and verification:Before the final selection, conduct the necessary testing and verification to ensure that the connector in the actual application of the performance in line with expectations.

PCB connectors are an integral part of electronic devices, they are responsible for connecting various components and ensuring stable transmission of signals and currents. Choosing the right connector is critical because it directly affects the performance and reliability of the device. During the design and production process, we should carefully consider the type of connector, electrical performance,mechanical characteristics and other factors to ensure the quality and stability of the final product.