Circuit board thermocouple connectors are specialised connectors used to connect thermocouple sensors to electronic circuit boards. Thermocouple sensors are commonly used to measure temperature and play a vital role in different environments (e.g. industrial, automotive, home appliances, etc.). The main function of the connector is to transfer the temperature and voltage signals from the thermocouple to a data acquisition system or controller for real-time temperature monitoring and control.

Thermocouples work on the basis of the thermoelectric effect, a technique used for temperature measurement. The thermoelectric effect describes the electric potential that occurs when two conductors of different materials are connected at opposite ends to form a closed loop, and when there is a difference in temperature between the two connections, this electric potential is known as the thermoelectric potential. In practice, the end in direct contact with the measured medium is called the working or measuring end, while the other end, which is not in direct contact with the measured medium, is called the cold or compensating end. The cold end is usually connected to a display meter or other auxiliary device to show the thermal potential generated by the thermocouple.

The thermal potential generated by a thermocouple consists of two components: the contact electric potential generated when two conductors are in contact, and the temperature difference electric potential generated by a single conductor due to temperature difference. It is worth noting that the magnitude of the thermoelectric potential depends primarily on the materials of the conductors that make up the thermocouple and the temperatures of the two connection points, and is independent of physical parameters such as the shape and size of the thermocouple. Thus, after the materials of the two electrodes of the thermocouple have been determined, the thermoelectric potential becomes a function of the temperature difference between the two connection points.

Thermocouples are usually classified into two main categories: standard thermocouples and non-standard thermocouples. Standard thermocouples follow national standards, which specify in detail the correspondence between the thermopotential and the temperature, the permissible range of error, and are accompanied by a standardised dividing table, making it easy to select a matching display instrument. In contrast, non-standard thermocouples do not meet these standard conditions, their application range or order of magnitude is often more limited, the lack of a unified index table, mainly for specific or special environmental measurements.

Depending on the fixture, thermocouples can be divided into six types: non-fixture, threaded connection, fixed flange, movable flange, movable flange angle scale form, and conical protection tube type.

In addition, in accordance with the performance of the structure and use of the particularity of the thermocouple can also be subdivided into four types: removable thermocouple, flameproof thermocouple, armoured thermocouple, and pressure spring fixed thermocouple, each of which is suitable for specific applications.

Improving the signal transmission stability of circuit board thermocouple connectors is critical to ensuring accurate temperature measurements:

Shielding Technology

The effects of electromagnetic interference (EMI) on thermocouple signals can be significantly reduced by using appropriate shielding techniques. Common shielding measures include:

Shielding material selection:The use of copper foil, aluminium foil or special shielding paint to provide shielding for the connector can effectively block external electromagnetic interference.

Shield construction:In the design of the shield, ensure its integrity and avoid cracks or openings, which can become paths for electromagnetic leakage.

Shield Grounding:Ensure that the shield is properly grounded to provide a low impedance return path to reduce the effects of interfering signals.

Grounding Design

Good grounding design is critical to improving signal stability.The following grounding methods can be considered:

Single point grounding: For low frequency signals, using a single point ground reduces the ground loop area and reduces interference.

Multi-point grounding: For high-frequency signals, multi-point grounding is recommended to reduce ground impedance and provide a better signal return path.

Hybrid grounding: In complex systems, a combination of single-point and multi-point grounding strategies are used to accommodate a variety of operating frequencies.

Connector Design

Connector design has a direct impact on signal repeatability and reliability and should focus on the following points:

Impedance matching: Ensure that the impedance between the circuit board thermocouple connectors and the signal source and load is matched to minimise signal reflection and distortion.

Pin spacing: Design proper pin spacing to avoid interference between signal lines.

Anti-vibration design: In the circuit board thermocouple connectors design, consider adding anti-vibration measures, such as the use of fastening devices, to reduce poor contact due to vibration.

Material Selection

The choice of materials on the circuit board thermocouple connectors and board has a significant impact on signal transmission performance:

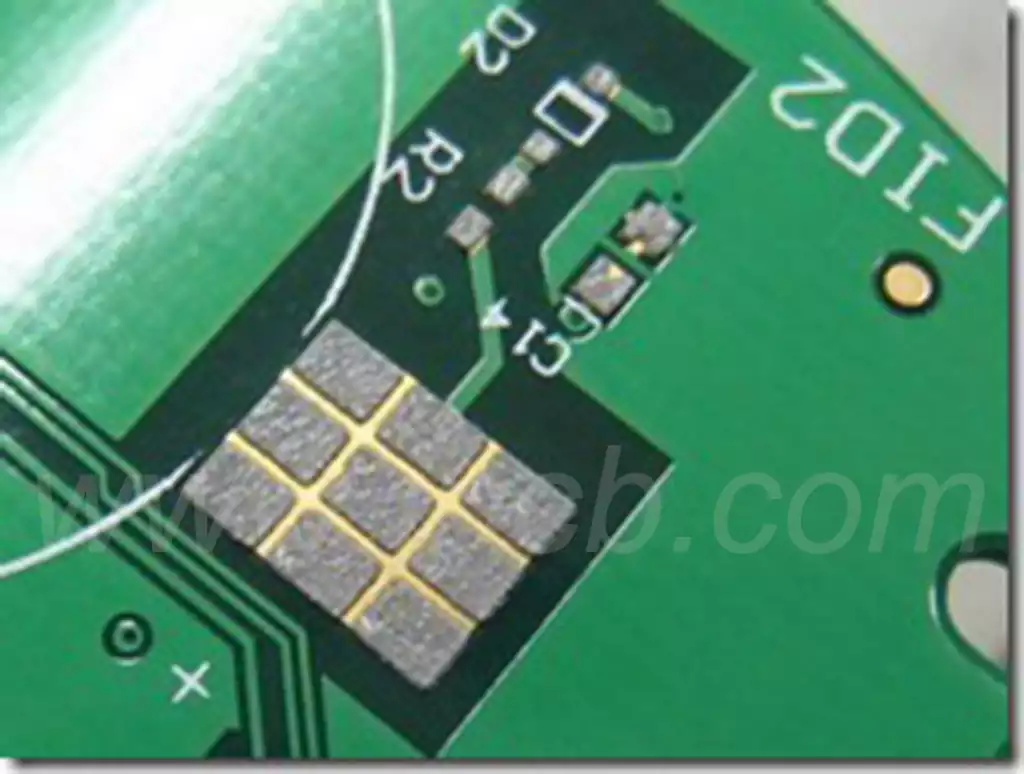

Conductive materials: Choose highly conductive materials, such as gold-plated copper, to improve signal transmission efficiency and reduce additional resistance losses.

Insulating materials: Use insulating materials with low dielectric constants and low dielectric losses to minimise signal attenuation.

Corrosion-resistant materials: In extreme environments, ensure that circuit board thermocouple connectors use corrosion-resistant materials to prevent oxidation and material degradation from affecting signal transmission.

Circuit board thermocouple connectors play a critical role in ensuring temperature measurement accuracy. Through the use of shielding technology, optimised grounding design, fine connector construction, and select materials, we are able to significantly improve the stability of thermocouple connector signal transmission.