Today we are going to explain the printed wiring board manufacturing process. If you are wondering, ” printed wiring board manufacturing process “, you have come to the right page. The manufacturing process of PCB (printed circuit board) is long and complex, and contains multiple steps. If any step is not given high attention, the performance of the finished product may be poor. In addition, if any step is skipped or the process is shortened, the performance of the PCB may be negatively affected. Therefore, it is crucial to ensure that each step is well monitored and should not be taken lightly.

Now, while all PCBs are produced through similar standard procedures, several steps of the process vary depending on the type of PCB. Single-sided PCBs, double-sided PCBs, and multi-layer PCBs differ from each other in terms of structure and function. Therefore, their manufacturing processes are also slightly different. Remember that the more sides a PCB has, the greater the complexity of its manufacturing process. Therefore, to understand the printed wiring board manufacturing process, you first need to know what type of PCB you need.

Once it is clear what type of PCB you want to manufacture, and all steps are carefully performed, you will get a fully functional printed circuit board that helps your device run smoothly. Read on to decode the “printed circuit board manufacturing process” in this step-by-step guide.

Design Review and Preparation of Production Tools.

The first stage of the PCB manufacturing process involves reviewing the manufacturing data package provided by the designer and preparing the manufacturing tools and CAM data.

Production Data Package

The output of the PCB manufacturing process design is a data package provided to the manufacturer in an industry standard format – Extended Gerber or ODB++. The Gerber file defines the copper layers, solder mask, component symbols. In addition, the manufacturing data package includes drill files, netlists, and general specifications.

Design for Manufacturing

Engineering will review the data package and verify that all the information required for manufacturing is clear and complete. We will also check that the design and specifications meet manufacturing capabilities.

Once all engineering issues are resolved, the necessary tools will be prepared for production.

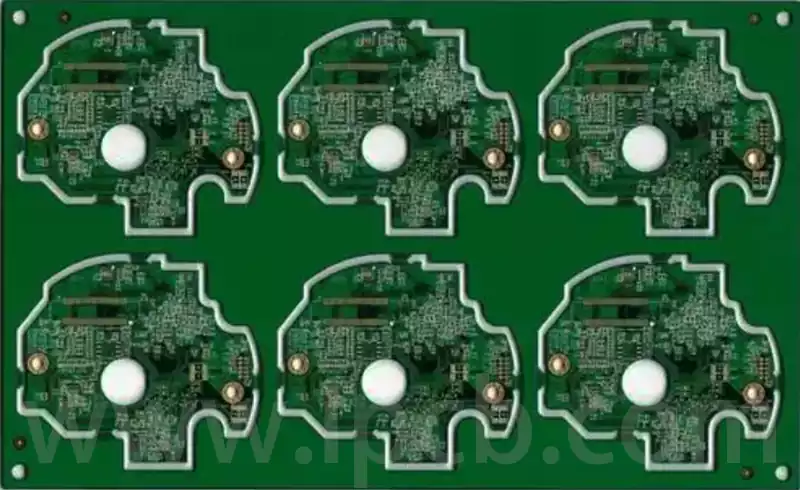

Preparation of Manufacturing Panels.

The manufacturer uses a standard manufacturing panel. The manufacturing panel must be designed to maximize material utilization, taking into account the size of the PCB and the manufacturing requirements: process control coupons, tool holes, and handling.

Preparation of Work Sheets (Photo Tools).

Using a laser plotter, a thin film is created for each PCB assembly layer. The laser plotter is in a darkroom with controlled temperature and humidity. The films are registered to each other to ensure perfect alignment between the layers.

The registration holes are later used to align the film during UV exposure. Another method is to use Laser Direct Imaging (LDI), using a CCD camera in the exposure machine to register the optical fixture.

Inner Layers

When preparing the inner layers, we take a base material of epoxy resin and glass fiber, coat it with copper foil on both sides and remove the excess copper, leaving copper traces only where we need them to realize the design of the circuit.

Base Materials

The core of the inner layer consists of epoxy resin and glass fiber cloth, which is coated with a thin layer of copper foil on both sides. In most cases, FR4 material is used.

The copper clad laminate on both sides is cleaned by a chemical cleaning process for the inner layer to remove oxides and possible contamination. At the same time, a rotating brush roller roughens the copper surface to ensure sufficient mechanical adhesion.

Dry Film Lamination

The core material passes through a heated roller pair (temperature: about 110º C pressure: 3-5 BAR). The surface of the copper becomes sensitive to UV light, so further processing is only carried out in the yellow light area.

Exposure of the inner layer

The film of this layer is placed on the laminate and the laminate layer is exposed to energy rich UV lamps. The traces of the PCB are transparent in the film while the underlying laminate is exposed to the UV lamp. The exposed portions will be chemically polymerized and the traces will harden.

The areas covered by the black portion of the film will not polymerize and can be washed away during the development process.

Development process

The development process is done by spraying the inner layer horizontally with a sodium carbonate solution followed by a clean water rinse and drying. The unexposed areas are now removed.

Etching of the inner layer core

The inner layer goes through another spraying, rinsing and drying process. This time with an acid solution. This process removes the copper from the exposed areas leaving only the copper traces and pads.

The thickness of the copper layer will determine the speed of the process. Thicker copper layers limit the fineness of the conductive pattern.

Stripping

The lacquer layer is removed by passing the material through a caustic soda solution.

Automated Optical Inspection (AOI)

The inner layer goes through an automated optical inspection to detect opens and shorts as well as correct circuit geometry compared to the original design data.

Preparation of Braun Oxide

The inner layer goes through a chemical surface treatment process to roughen the surface and improve adhesion between the PREPREG resin and the copper surface during lamination.

Lamination

Material Layering

Before lamination, the layers are built up. Start with a copper foil on the bottom (this will be used to build the bottom outer layer). On top of the copper layer is the PREPREG layer, on top of the PREPREG is the inner layer separated by a PREPREG layer, and on top of the inner layer is the PREPREG layer and a second copper foil (which will be used to build the top outer layer).

PREPREG is a partially cured epoxy resin with glass fibers that is polymerized by the PREPREG manufacturer. It is used as an insulating material and adhesive between PCB component layers.

High-Pressure Lamination

The built-up layers are laminated under vacuum, high temperature, and high-pressure pressure. Multiple printed circuit boards, separated by separators, are pressed simultaneously. The heat and pressure cause the epoxy resin in the PREPREG to melt and harden, while the pressure causes the printed circuit boards to melt.

Trimming

Flash (material hanging off the laminate is routed away, leaving a clean panel that looks like a single laminate.

Drilling

X-RAY Analysis

As a preparatory stage, an X-RAY is used to identify invisible pads in the inner layers. With X-ray analysis, these pads can be detected and new reference holes for drilling calculated

Drilling

The PCBs are finished on a high-speed CNC drilling machine (up to 280,000 rpm). The holes drilled must be as clean and smooth as possible to enable high-quality copper plating of the holes. Optionally, up to 3 panels can be stacked and drilled simultaneously.

The panels are placed between a base plate and a top aluminum plate. The base plate prevents the drill from penetrating the drill and allows drilling deeper than the panel, avoiding burrs. The aluminum top plate avoids burrs and prevents the drill from deflecting. Both plates protect the surface of the panel from damage and scratches.

Brushing and Decontamination

After drilling, the surface of the PCB is mechanically brushed with an oscillating and rotating brush roller. The drilled holes are cleaned with a permanganate solution or oxygen plasma to remove resin that may have stuck to the copper. Resin residues on the copper may prevent proper conductivity between the plated layer in the hole and the conductors in the layer.

Electroless Plating

Non-electrolytic Plating

In order to establish electrical connections between the drilled holes and all layers, a conductive film of about 0.5-0.7 microns thick is made with chemical copper. This conductive layer is the basis for the copper plate process applied later.

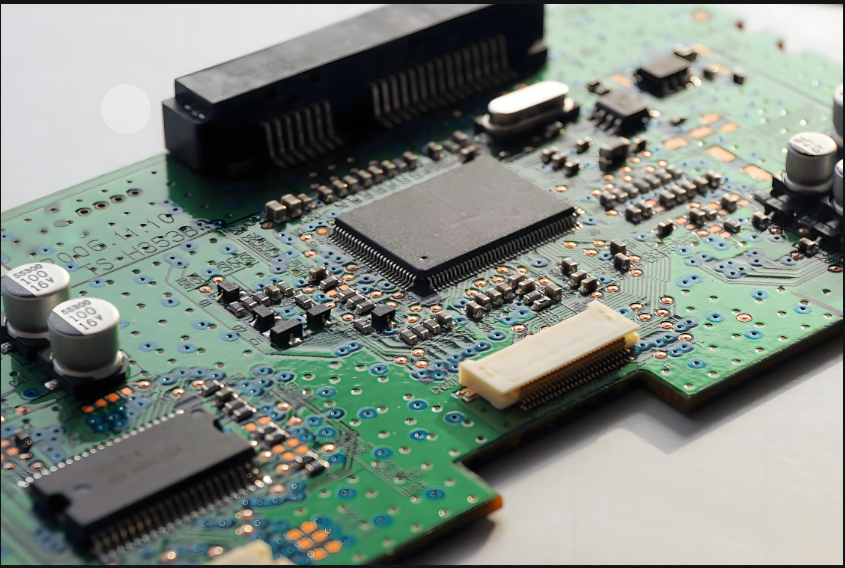

Outer Layers and Plating

This process is similar to the one adopted when building the inner layers. The difference is that in this step, we use the electrolytic copper plating process to plate the holes and traces and pads of the outer layers.

Dry Film Lamination of the Outer Layers

This process corresponds to the one adopted for the inner layers. The panel passes through a pair of heated rollers (temperature: about 110º C, pressure: 3-5BAR). The surface of the copper becomes sensitive to UV light, therefore, further processing is performed only in the yellow light area.

Contact and Development

This process corresponds to the process for the inner layers. However, in this process, a negative exposure process is used. The conductive lines are not covered by resist and can be plated by copper plating. The areas between the conductive lines are covered with a polymeric laminate.

Electrolytic Copper Plating

All wires and holes are coated with a conductive electrodeposited copper layer. The holes form an electrical connection between the conductors of the layers, and a good connection requires 20-25 microns of copper on the hole wall. Therefore, the overall copper thickness of the outer layer is determined by the copper thickness of the material and the 25-30 microns added during the electroplating process .

Tinning

The second electroplating process is to protect the copper conductors during the following etching process, so this layer is often also expressed as etching resist.

Outer Dry Film Stripping

The dry film is removed to expose the copper layer for etching.

Etching and Tinning

The etching process is carried out to remove the excess copper, leaving only the traces and copper in the pads protected by tinning. Then, the tin is removed with nitric acid.

Solder Paste

Solder resist is applied to most printed circuit boards to protect the copper surfaces that will not be protected by solder during assembly and to prevent solder shorts during assembly.

The panel is brushed and cleaned.

Both sides of the panel are coated with 15-25 microns thick epoxy solder mask ink.

Using a UV printer and phototool film, the solder mask is hardened in the areas where we want to retain the solder mask. We want to retain the solder mask.

The panel is processed through a developer that strips the solder mask from the areas that should be exposed. The areas that should be exposed.

The masked solder is further hardened in an oven.

Surface Finish

Surface finish applies a solderable finish to the copper surfaces not covered by solder mask. This finish protects the copper until the components are assembled and soldered to the PCB. There are several surface finishes to choose from. The most commonly used are hot air leveling (HAL) and electroless nickel immersion gold (ENIG).

HAL

The HAL process forms solder on all pads. The entire panel is immersed in liquid solder, which is removed from the solder by hot compressed air. Excess solder (which has not bonded to the exposed copper) is blown away, while the copper pads and holes are left gold plated.

The solder used in this process is either a Tin”Lead alloy or just Tin (lead-free).

ENIG

In this process, Nickel is chemically deposited on Copper and then a thin layer of Gold is deposited on top of the Nickel. The entire process is automated and moves the panel through a series of cans, cleans the Copper, deposits a 3-5 micron layer of Nickel and a minimum 0.05 micron layer of Gold.

Hard Gold Plating

Edge connectors are electroplated with 1-1.5 microns of Gold over 4-5 micron Nickel. This type of plating is done in cases where it needs to withstand the erosion of multiple insertions.

Legend Printing

The legend is printed on the PCB using a screen printer.

Paths

The fabrication panel is cut into individual PCBs using a CNC system and the PCBs are machined to their shape as per the design data.

Electrical Testing

Each PCB is electrically tested as per the design data using a “Bed of Nails” adapter or a Flying Probe Tester.

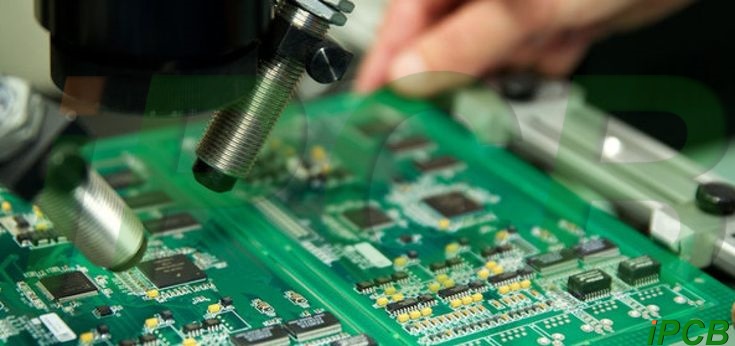

Final Quality Control

This is the final inspection of the finished PCB. It checks for any cosmetic defects such as scratches and impurities using IPC600 as a reference.

If you are looking for a trustworthy company to outsource your PCBs For manufacturing projects, check out iPCB’s website. As one of the best manufacturers in the industry, they offer a variety of services to ensure a satisfying customer experience and take every step of the printed wiring board manufacturing process seriously.