I believe that many people will confuse flux paste with solder paste. In fact, they are different. Solder paste is tin paste. Its main component is a paste composed of metal alloy powder. But flux paste is different. It mainly plays a role of flux. Its main components are rosin, activator and solvent. A certain proportion of flux paste will be added to the tin paste during the production process.

- First of all, we can clearly see from the appearance that flux can be divided into solid, liquid and gas. The common and often mentioned flux in the soldering industry is liquid, while the so-called flux paste and tin paste are paste. The color of flux paste is transparent and yellowish, and the color of tin paste is gray or black.

- The main components of flux and flux paste are rosin. The difference is that the production process is different, and the proportion of solvent added is different to form different states. Flux is processed into a liquid by rosin, activator and some other additives, and is often used in conjunction with tin bar wave soldering process.

Solder paste is a paste flux material made from raw rosin and special chemicals. It plays an auxiliary welding role in the component welding process. It is a synthetic substance in the production process of solder paste. It is often used together with solder paste, or used with tin wire for post-welding and repair welding after the patch is completed.

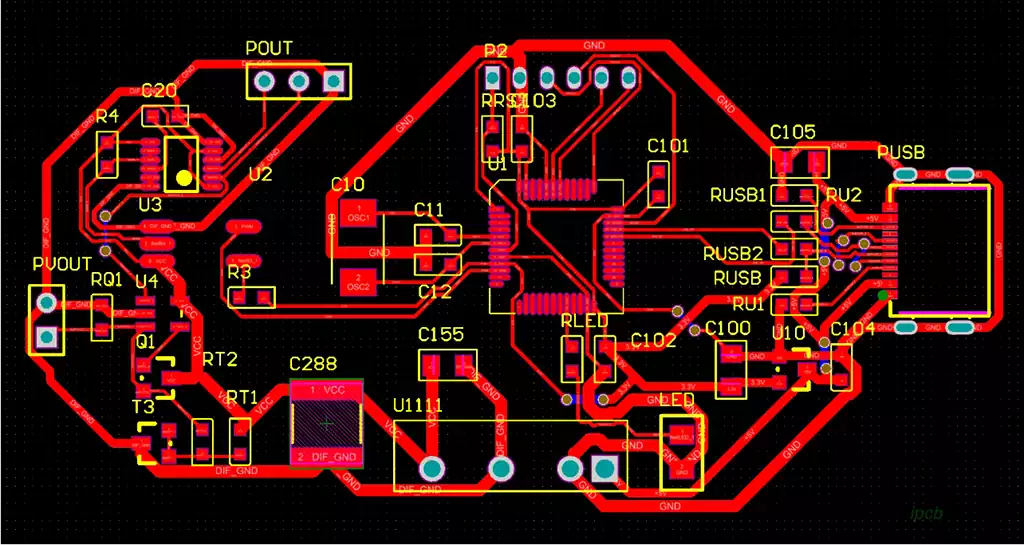

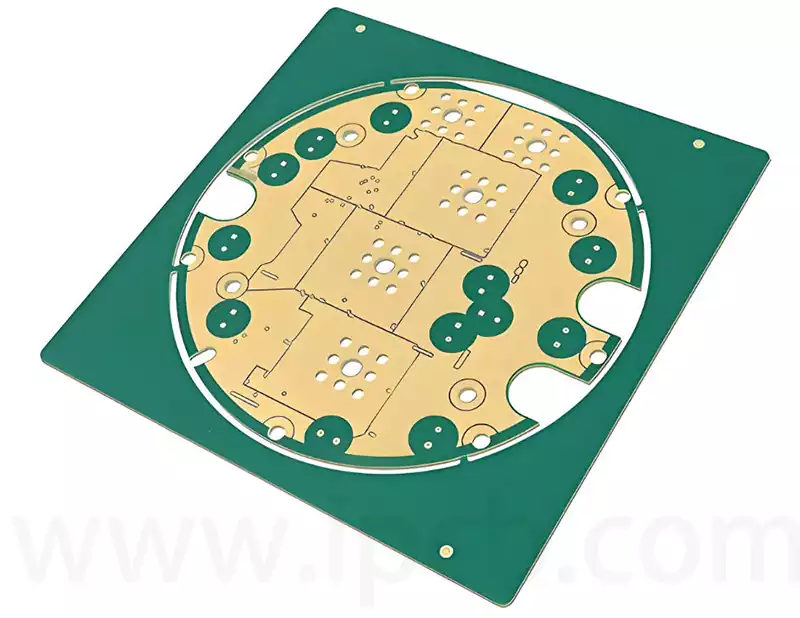

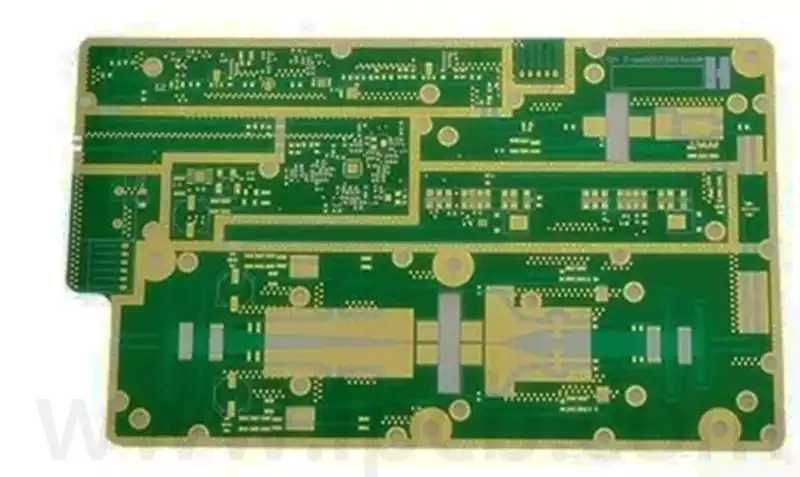

Solder paste is a paste mixture formed by mixing solder powder, flux and other surfactants, thixotropic agents, etc. It is a new type of welding material that came into being with SMT. It is mainly used for welding electronic components such as PCB surface resistors, capacitors, and ICs in the SMT industry.

- Both flux and solder paste play an auxiliary welding role. In addition, they can remove surface oxides and prevent oxidation during welding operations; reduce the surface tension of the material, thereby improving the welding quality and significantly improving the wetting performance. Solder paste is like a medium between welding. Its main function is to weld electronic components. It can directly weld different components together, just like building a bridge.

Flux, solder paste and solder paste are all indispensable materials in welding. The above are the differences between the three. You must pay special attention when purchasing welding materials.

Rosin

Ingredients: Rosin mainly comes from pine trees. It is the solid residue after the distillation of rosin. The main components are resin acids (such as abietic acid and pimaric acid), as well as some fatty acids and neutral substances. Features: Rosin is a transparent brittle solid that is insoluble in water but soluble in solvents such as alcohol. It is a natural surfactant that can effectively remove oxides on the welding surface and help the solder to adhere better. Uses: In circuit board welding, rosin is often used as the basic raw material of flux. In addition, rosin is also widely used in the field of musical instruments, such as applying it to the bow hair of stringed instruments to increase friction.

Flux

Ingredients: Flux consists of rosin, activator, solvent and some additives. Special ingredients may include corrosion inhibitors, antioxidants, etc.

Features: Flux can not only remove oxides on the welding surface, but also prevent the metal surface from being oxidized again during the welding process, and improve the wettability of the solder. Its melting point is much lower than that of solder materials, and it can quickly melt and cover the solder surface during welding.

Uses: Flux is widely used in the welding process of electronic products, such as SMT (surface mount technology) and PCB (printed circuit board) manufacturing. It can significantly improve welding quality and reliability.

Flux paste

Ingredients: Flux paste is an upgraded form of flux, usually in the form of a , containing metal powder, rosin, organic acid, thixotropic agent, activator, etc. Features: In addition to the function of flux, flux can also reduce the surface tension of the material to be welded, so that the solder can be spread better. It is usually used in welding scenes that require high precision and high automation. Uses: Flux paste plays an important role in welding in the fields of clocks and watches, precision parts, medical devices, etc. Especially in the SMT automatic mounting process, flux paste is an indispensable welding auxiliary material.

Solder paste

Ingredients: Solder paste is mainly composed of tin powder and some flux, and the type and content of flux will vary according to the specific application. Features: Tin paste is a soft, easily deformable welding material with a certain viscosity. After heating, the solder paste will melt quickly and form a stable welding connection with the pad. Uses: Tin paste is the core material in the SMT welding process and is widely used in the connection between electronic components and PCBs. It can effectively reduce the oxidation of solder and improve the stability and reliability of welding.

- How to distinguish these four types

- Different composition materials

Solder paste, tin paste, and solder paste are essentially the same thing, that is, a paste-like object produced by solder paste manufacturers for SMT welding process. The English names of these three products are solder paste. Among these four products, many people tend to regard solder paste and flux paste as one product. In fact, there is an essential difference between these two products. Solder paste is solder paste, and the main component is a paste-like object mixed with alloys composed of metal tin, silver, copper, bismuth, etc. and flux. The main component of flux paste is equivalent to flux, which only plays a role in auxiliary welding. Its main components do not contain metal tin, silver, copper, and bismuth. The main components are rosin, activator, and solvent. In layman’s terms, flux paste is a material that needs to be added during the production of solder paste. Flux paste is only a part of solder paste. Solder paste can be made by mixing flux paste with appropriate amounts of metal tin, silver, copper, and bismuth.

- Different ways of use

Solder paste, solder paste, and solder paste are the same material. For the sake of convenience, lead-free solder paste manufacturers will uniformly refer to them as solder paste for easy explanation. Solder paste is to add an appropriate amount of metal alloy components to the flux paste. The main purpose is to complete the welding of electronic components and circuit boards, and to connect electronic components and circuit boards from the mechanical and electrical principles. The main function of flux paste is to provide suitable fluidity and wetting properties as a particle carrier of metal alloys. Adding an appropriate amount of flux paste to the metal tin, silver, and copper alloy during the welding process is conducive to heat conduction. Increase the wettability of the metal material surface to be welded, reduce the metal surface tension, improve the wetting performance of the entire metal alloy, and then the liquid after the flux paste is melted during the high-temperature heating process can also prevent the metal surface from being oxidized, and can also remove the oxides on the oxidized metal surface. Form a protective layer and some residues at the welding point on the circuit board to protect the solder joint, which can avoid further corrosion. These four materials are completely different in actual use. Generally, lead-free solder paste manufacturers produce four different materials at the same time. The majority of SMT manufacturers can choose in the actual application process.

Three, four kinds of materials become two, and even a fool can tell them apart

From the above analysis of solder paste, it can be seen that these four materials are actually two products, namely solder paste and flux paste. If you buy these four products from a lead-free solder paste manufacturer, you can open the lid and take a look, and you can see them at a glance with your naked eyes. Lead-free solder paste is gray in color, while lead solder paste is black in color, and flux paste is yellow in color. Because the materials used by lead-free solder paste manufacturers are different, the original colors of these two products are inconsistent. Solder paste is a mixture of flux paste and metal powder. The color of solder paste itself is a mixture of flux paste and metal powder. The color of lead-free solder paste is a combination of the yellow color of flux paste and the silvery white color of metal powder.

Solder paste is obviously different from solder paste. The main function of flux paste is to assist soldering. Its core ingredients include rosin, activator and solvent. In the process of making solder paste, flux paste is added in a certain proportion to improve its soldering performance.

So, what role does flux paste play in the soldering process?

- As a carrier of tin powder particles: flux paste provides suitable rheology and wet strength for tin powder particles, ensuring that heat can be efficiently transferred to the soldering area, reducing the surface tension of the solder, and thus preventing re-oxidation of the solder and soldering surface during soldering.

- Cleaning and protection: flux paste can also remove the oxide layer of the soldering surface and tin powder particles, and form a protective layer and a safe residue layer on the surface of the soldering point to ensure the quality of soldering.

- Flexible ratio: solder paste can be mixed with various types of solder powder (such as tin, silver, copper, bismuth, lead, etc.), and is suitable for welding in different temperature ranges (such as 100-260℃). The solder paste after this ratio has the characteristics of good solderability, continuous printing and low residue.

In appearance, solder paste and solder paste are also obviously different. The solder paste is usually yellowish, while the solder paste may be gray or black, because the solder paste contains tin powder.

The difference between rosin and solder paste and solder paste

- Different raw materials:

Rosin: solid pine resin, the raw material for making solder flux. It mainly helps to remove oxides on the pads during the welding of circuit board parts, which is conducive to the welding of solder. The main components of rosin are abietic acid and pimaric acid. Rosin is the main component of solder paste.

Solder paste: The main component of solder paste is rosin, as well as solvents such as surfactants.

Solder paste: The main component of solder paste is metal raw materials, and then solder paste solvents and other raw materials are added to make solder paste. Solder paste generally refers to lead solder paste, lead-free low-temperature solder paste, medium-temperature solder paste, high-temperature solder paste, etc., which directly play a role in welding. - Different corrosiveness:

Flux paste: It is a substance that assists welding. The main components of the liquid are isopropyl alcohol, rosin, organic acid, etc. It is used for welding parts of electronic circuit boards to clean the surface oxide layer of the metal in the welding part and help the solder flow and expand. Remove the oxide layer of the welding surface and tin powder particles, and form a protective layer and a safe residue layer on the surface of the welding point.

Rosin: Rosin can only be used as a raw material to synthesize products with other chemical elements. - Different functions and effects:

Solder paste: It directly plays a role in welding. It is mostly used in the SMT industry and the LED industry

Flux paste: Removes metal surface oxides and helps welding. High-end solder paste is mostly used for electronic mobile phone and computer products. The lead-free and halogen-free solder pastes required by PG HW foundries are all high-end products

Rosin: It is just a simple surfactant that allows the solder to fully infiltrate the welding surface.

Choose good tools for soldering to avoid all trouble. It is not difficult to distinguish between flux paste and solder paste.