The PCB substrate is the insulating core component in its construction, which carries the important responsibilities of supporting components, dissipating heat and resisting damage, as well as maintaining dimensional stability and providing electrical insulation.

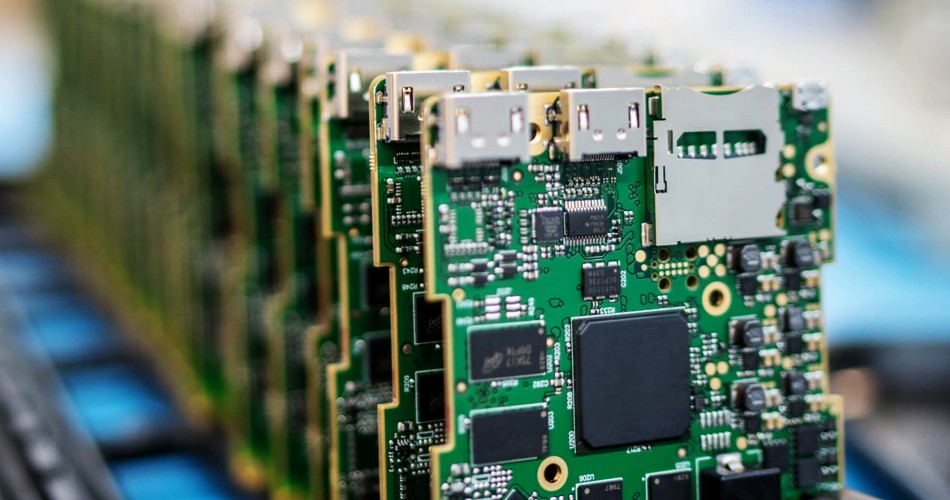

The pcb substrate is often covered with a conductive layer on one or both sides, which is responsible for building the alignment pattern and paving the way for signal transmission between components, thus making the PCB a fully functional device.

The substrate may also consist of one or more plates stacked by means of an adhesive. Of these, single-layer substrates are the most basic, while multi-layer substrates are used in complex electronics due to their higher interconnectivity.

As for the material of the PCB substrate,it is usually built from non-conductive or composite materials.In most circuit boards,we will see a combination of epoxy adhesive and glass fibre for strength.This combination creates a cost-effective dielectric that is sufficient for most application scenarios.

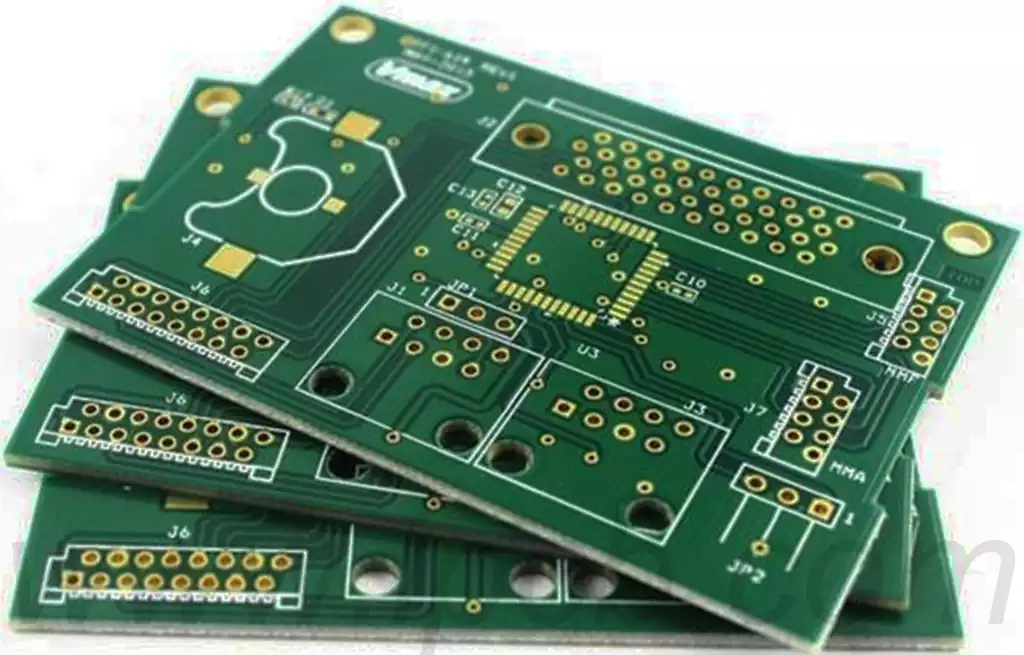

Common PCB board types

FR-4 glass fibre board: one of the most common PCB materials, laminated from glass cloth and epoxy resin, with good electrical properties, mechanical properties and thermal stability, suitable for most application scenarios.

Aluminium substrate: good heat dissipation performance, suitable for high temperature and high power density applications, as well as good mechanical properties and anti-corrosion properties

Ceramic substrate: a high-performance PCB material with excellent electrical properties, thermal stability and mechanical properties, suitable for high-temperature applications.

Flexible substrates: suitable for applications that require bending or adapting to smaller spaces, such as polyimide, PTFE and PET materials

Special materials

Metal substrates: provide good thermal and dimensional stability by replacing reinforcements such as epoxy glass cloth with a metal (usually aluminium) plate

PTFE glass fibre plates: provide excellent dielectric properties, high temperature resistance, humidity resistance and chemical stability, and are suitable for high frequency and microwave electronic communication equipment.

High Frequency Applications

Choose low-loss materials: In high-frequency circuits, materials with low loss, stable Dk/DF parameters, low dispersion, and small coefficients of variation with frequency and environment should be selected

Avoid FR-4: FR-4 materials are not suitable for circuits that generate high frequencies

Use smooth copper foil: To mitigate losses at the highest frequencies, smooth copper foil should be used.

When selecting PCB boards, the following key factors need to be considered:

Operating environmental conditions: The conditions of use that the board needs to withstand are an important basis for selecting a substrate. For example, in the high-temperature environment of the circuit board should be selected with good thermal performance of the material, such as aluminium substrate.

Electrical properties: PCB substrates must have the required electrical characteristics to ensure better signal quality and power efficiency. Radio frequency (RF) boards require a stable dielectric constant, while power electronics require boards that can withstand higher voltages without failure.

Mechanical Properties: Good mechanical properties reduce damage during manufacturing and increase board durability. These properties include tensile strength, flexural strength and peel strength.

Thermal Properties: Thermal properties determine the suitability of a material for high-temperature applications, including the ability to dissipate or resist heat, as well as indicators such as decomposition and glass transition temperatures. Thermal conductivity and coefficient of thermal expansion are also important parameters.

Chemical Resistance: Suitable substrates should be resistant to chemical and moisture damage in the manufacturing process and application environment, such as corrosive materials and PCB cleaners.

Cost: The cost needs to be balanced against the quality required to meet the performance requirements.Expensive PCB laminates offer better quality, but may also increase the price of the final product.

Manufacturability: Some PCB substrate materials require more care than others or require more advanced equipment to manufacture. Materials that are easy to use can reduce PCB manufacturing costs and increase yield and scalability.

Flame Retardant: In order to ensure the safety of electronic devices, the flame retardancy of PCB boards is an important consideration.

As a core component in electronic devices, the choice of material and optimisation of performance of PCB substrates are directly related to the reliability, efficiency and safety of the entire device. When selecting PCB boards, we must comprehensively consider a number of key factors to ensure that the selected material can meet the design requirements of the equipment and practical application needs.