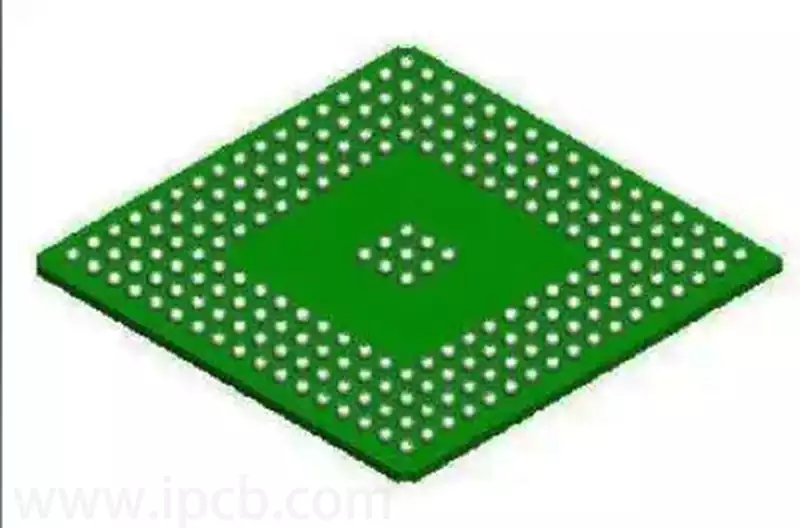

BGA pad diameter tolerance, that is, the maximum allowable deviation range of the diameter of the ball grid array package pad. In the manufacturing process of electronic components, the control of tolerance is crucial, which directly affects the quality of the pad and the reliability of electronic products. Reasonable tolerance range can ensure that the pad in the production, assembly and subsequent use of the process of performance stability, reduce the defective rate, improve the overall quality of the product.

BGA (ball grid array package) solder ball diameter tolerance requirements are very strict, usually controlled within ± 10%, the main reason:

Implicit constraints of IPC and JEDEC standards on solder ball diameter tolerance

- IPC-7351 specification on pad design

IPC-7351 standard although not directly on the tolerance of the solder ball diameter to make clear provisions, however, the development of its pad size design rules, in fact, the consistency of the solder ball put forward strict requirements. The standard specifies that pad diameters should generally be 20% – 25% smaller than solder ball diameters. For example, when the nominal diameter of the ball is 0.5mm, the pad diameter should be designed to be 0.4mm (i.e. 20% smaller). If the actual diameter of the ball is outside the ±10% tolerance (e.g. 0.55mm or 0.45mm), there is a high risk of mismatch between the pad and ball size, which can lead to risky problems such as poor wetting or bridging. - JEDEC regulations on coplanarity and dimensional compatibility

JEDEC standards (e.g. JESD22 – B111) set clear limits on the co-planarity of BGA solder balls (usually ≤150μm). The coplanarity of the solder balls depends on the consistency of their diameters, and once the tolerance is out of the standard range, it will directly lead to an increase in the difference in the height of the solder balls, which will undoubtedly exacerbate the stress concentration phenomenon during the soldering process and increase the risk of false soldering. In addition, JEDEC in the package design guidelines stressed that the size of the solder ball must be strictly adapted to the PCB pads, stencil aperture and other process parameters, and tolerance control is the basis for achieving this adaptation to ensure. - The extended impact of standards in high-density packaging

With the widespread use of fine-pitch BGAs (e.g. 0.35mm pitch), both IPC-7351 and JEDEC guidelines require further optimisation of the ratio of solder balls to pad size. For example, for the diameter of 0.3mm solder ball, need to match the diameter of 0.24mm pad (i.e., reduced by 20%), once the tolerance exceeds the range of ± 10%, will directly lead to the pad can not accommodate the solder ball or the emergence of insufficient solder, which affects the strength of the welding.

Process Suitability: The Ripple Effect of Tolerance Overruns

Conflict between solder paste printing volume and stencil design

The tolerance of the solder ball diameter has a direct impact on the stencil opening size. Once the tolerance exceeds the standard range, the stencil in the design of the opening size, if the maximum possible diameter of the ball to design, will make the small diameter of the ball corresponding to the amount of solder paste is not enough, and thus the formation of the phenomenon of false soldering; on the contrary, if the smallest diameter to design, may lead to the overflow of the solder paste and short-circuit problems.

Reflow thermodynamic balance of the imbalance

When there is a large difference in the diameter of the solder ball, it will lead to uneven distribution of heat capacity. Larger solder balls take longer to melt, while smaller balls may collapse prematurely, resulting in cold or continuous soldering. A tolerance range of ±10% is a critical threshold for balancing heat distribution with solder flow.

Positioning deviations in mounter vision systems

Modern mounters rely heavily on the geometric characteristics of the solder balls to achieve accurate positioning. If the difference in solder ball diameter exceeds ±10%, the vision system may misjudge the position of the solder ball centre, resulting in an offset in placement (>50μm offset), which can significantly increase the risk of bridging.

Reliability needs: from mechanical strength to signal integrity

Impact of mechanical stress and thermal fatigue life

Inconsistencies in solder ball diameter can lead to differences in solder joint height, exposing some solder joints to higher stresses. Studies have shown that solder joints with diameter tolerances exceeding the limit by 10% are more than three times more likely to fail in thermal cycling tests.

Potential Risks to Electrical Performance

In high-frequency application scenarios, differences in solder ball sizes can change the impedance consistency of the signal path, which can lead to delays, reflections, and other problems. For example, in GPU packages, if the tolerance is exceeded, it may trigger clock signal jitter, affecting the calculation accuracy.

Uniformity Requirement of Heat Dissipation Path

BGA solder balls are the core path for chip heat dissipation. Exceeding the tolerance of the diameter will cause the local thermal resistance to rise, forming a ‘hot spot’ and accelerating the aging of the device. Experimental data show that the tolerance over ± 10% of the solder joints, the thermal resistance difference of up to 25%.

In electronics manufacturing, BGA solder ball diameter tolerance is a small value, but the product quality and reliability has a non-negligible impact. From the standard specification on the consistency of the solder ball requirements, to process adaptation, reliability needs and other aspects of the correlation, all show that it is essential to control this tolerance. Manufacturers need to pay attention to tolerance control, through a reasonable process and strict testing to ensure that the diameter of the solder ball in line with the standard, in order to improve the overall quality of electronic products, and promote the stable development of the industry.