RO4350B is a commonly used high-frequency printed circuit board (PCB) material produced by Rogers Corporation in the United States. This material is used in wireless communications, radar systems, medical devices and other high frequency electronic equipment.The dielectric constant of RO4350B is approximately 3.48.This value was measured at a frequency of 1 GHz.Typically, the dielectric constant of RO4350B varies from frequency to frequency, but it exhibits relatively stable properties over the entire frequency range.

What is the temperature of Rogers RO4350B?

Rogers RO4350B is a commonly used high-frequency PCB material for a wide range of radio frequency (RF) and microwave applications. Its temperature coefficient is an important parameter for evaluating the stability of the material’s electrical properties under different temperature conditions, especially in high frequency applications where temperature variations may have a significant impact on signal transmission.

RO4350B has a temperature coefficient of approximately +0.0004/C. This low temperature coefficient means that the change in dielectric constant of RO4350B is relatively small during temperature changes, thus maintaining good signal integrity and stability. This is especially critical for high-frequency, RF applications, as it can help reduce signal distortion and transmission loss due to temperature changes.

What is the conductivity of RO4350B?

RO4350B has a thermal conductivity of 0.69 W/m/K. The material exhibits excellent thermal diffusion in the dielectric layer, which effectively prevents components from generating hot spots. This helps to maintain signal stability and extend component life under high RF power conditions.

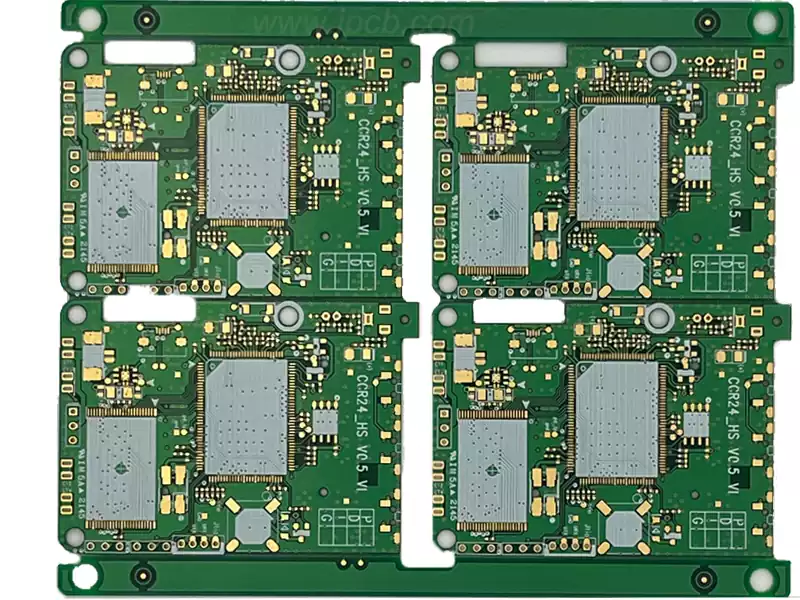

Rogers RO4350B high-frequency board board is fully compatible with traditional PCB manufacturing technology, do not need to do through-hole copper-plated special pre-treatment (PTFE boards need to do plasma treatment) or other pre-treatment processes, solder resist process can also be ground plate. Compared with the traditional microwave materials laminate price is lower, so it is widely used in active devices and high power RF design requires fire rating UL 94V-0.

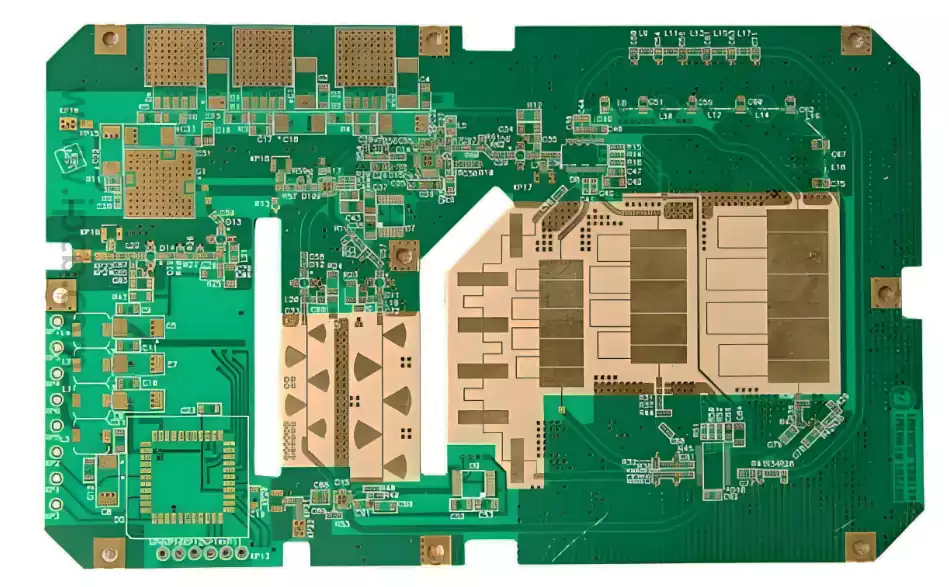

RO4350B is particularly suitable for high-frequency circuit board applications such as RF antennas and 5G antennas due to its excellent electrical characteristics and processability, demonstrating its wide applicability in the communications field.

Rogers RO4835 high-frequency board is an innovative low-loss thermoset composite material that combines the advantages of hydrocarbon resins and ceramic fillers, and is specially designed for civil and high-end PCB applications. It has not only passed the automotive industry’s stringent safety tests, but has also become the material of choice for automotive electronics such as automotive collision avoidance radar antennas and 76-81GHz automotive millimetre wave radars due to its excellent performance.

RO4835 high-frequency board is known for its excellent low-loss characteristics, which significantly improves the performance of high-frequency circuits while effectively reducing circuit manufacturing costs. The material is a perfect match for Rogers’ exclusive LoPro reversed copper foil process, which is especially suitable for application scenarios with high requirements for low insertion loss. In addition, RO4835 is compatible with traditional PCB manufacturing processes, eliminating the need for special plasma treatment before through-hole copper plating as is the case with PTFE materials, simplifying manufacturing steps, even such as board grinding in soldermasking processes.

Key Benefits:

Up to 10 times better oxidation resistance than traditional thermoset materials.

Excellent electrical properties for high frequency applications.

No bubbles or delamination to ensure material quality.

Reliable plated through-hole technology for enhanced circuit connection stability.

Consistent performance over the entire circuit processing temperature range.

Typical Applications:

Automotive radar and sensor systems

Point-to-point microwave communication transmissions

Power amplifier modules

Phased array radar technology

Electrical Performance Comparison

RO4350B has a low and stable dielectric constant, making it suitable for high frequency designs that require tight impedance control and a wide frequency coverage up to 77 GHz. RO4350B is widely used in 5G base stations, satellite communications and high frequency radar systems due to its low loss and stable dielectric properties.

RO4835, on the other hand, is known for its excellent oxidation resistance and is especially suitable for applications with high ambient temperatures and stringent requirements for long-term reliability, such as automotive millimetre-wave radar (76-81 GHz), where its electrical characteristics are close to those of RO4350B, but it is better suited for applications with high heat and weathering resistance requirements.

Production process and ease of manufacturing

Both materials are compatible with traditional FR-4 processing techniques, eliminating the need for special plasma pre-treatments common to PTFE materials, making them less difficult to manufacture. RO4835, in particular, simplifies the production process by eliminating the need for complex treatments prior to copper plating of the through-holes, and makes it easier to grind the boards during soldermasking, which greatly improves manufacturing efficiency and reduces production costs.

The RO4350B also supports standard double-sided and multilayer PCB production methods, providing high mechanical strength and stable processing for complex multilayer designs.

RO4350B is widely used in high-frequency communications and radar applications due to its stable electrical performance and good manufacturing compatibility, while RO4835 meets the needs of harsh environments, such as automotive electronics, with its excellent oxidation and high-temperature resistance. Together, they promote the development of high-frequency PCB technology and help achieve more efficient and reliable electronic product design.