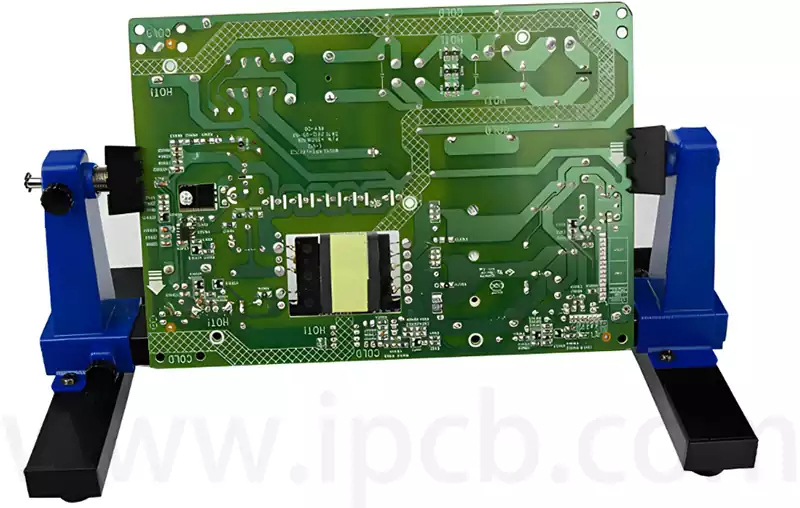

A pcb board clamp is a fixture used to hold and clamp circuit boards. It plays a very important role in the assembly and manufacture of circuit boards. There are many types of pcb board clamps and different types of clamps are used for different boards. According to the shape and size of the circuit board, there are many types of fixtures, mainly pneumatic fixtures, vacuum fixtures, elastic fixtures and so on.

The functions of pcb board clamp mainly include the following:

Fixing PCB: Ensures that the PCB remains stable during operation.

Positioning: Helps to accurately position the PCB for various operations.

Protecting the PCB: Reduces the risk of damage to the PCB during operation.

Improve work efficiency: Make the operation more convenient and efficient.

Ensure Accuracy: Helps ensure the accuracy and consistency of operations.

Convenient operation: Provides better operating conditions for operators.

The basic structure of the pcb board clamp includes the fixture body, positioning elements, clamping elements and support elements.

- Fixture body

Fixture body is the main part of the pcb board clamp, generally made of aluminium alloy material, with sufficient strength and rigidity. The structural elements of the fixture body are fixture base, fixture plate, fixture end face, etc. These parts need to be reasonably designed to ensure the stability of the fixture and clamping effect. - Positioning elements

Positioning elements are parts of the fixture used to locate the circuit board, mainly including locating pins, locating holes and so on. Positioning elements should be designed according to the size and shape of the circuit board for a reasonable layout to ensure that the circuit board in the fixture in an accurate and stable position. - Clamping components

Clamping components are used to clamp the circuit board in the fixture parts, mainly including pressure plate, screws, etc.. The design of the clamping element should take into account the size and shape of the circuit board to ensure that the fixture can clamp the circuit board, while not causing damage to the circuit board. - Support elements

Support elements are parts of the fixture used to support the circuit board, mainly including support pins, support blocks, etc. The design of support elements should take into account the size and shape of the board to ensure that the fixture can clamp the board without damaging it. The design of the support element should take into account the weight and shape of the circuit board to ensure that the support element can withstand the weight of the circuit board, while not causing damage to the circuit board.

Types and Functions of pcb board clamp

- Pneumatic Fixtures

Pneumatic fixtures are a type of pcb board clamp that generates upper and lower clamping force through compressed air. It is suitable for clamping small and medium-sized circuit boards. Pneumatic fixtures are characterised by high speed and high accuracy, while the clamping force is relatively small. - Vacuum fixture

Vacuum fixture is a kind of fixture that uses vacuum suction cups for clamping. It is suitable for clamping larger circuit boards, and its clamping force is much larger than that of pneumatic fixtures. The advantage of the vacuum fixture is that the clamping force can be adjusted, and at the same time can avoid the deformation of the circuit board caused by too much clamping force. - Elastic fixtures

Elastic fixtures are clamping fixtures that use elastic materials to achieve clamping without the need for external energy input. It is often used when clamping small circuit boards. Its advantage is that the clamping force can be automatically adjusted as needed, and at the same time can avoid deformation and damage caused by excessive clamping force.

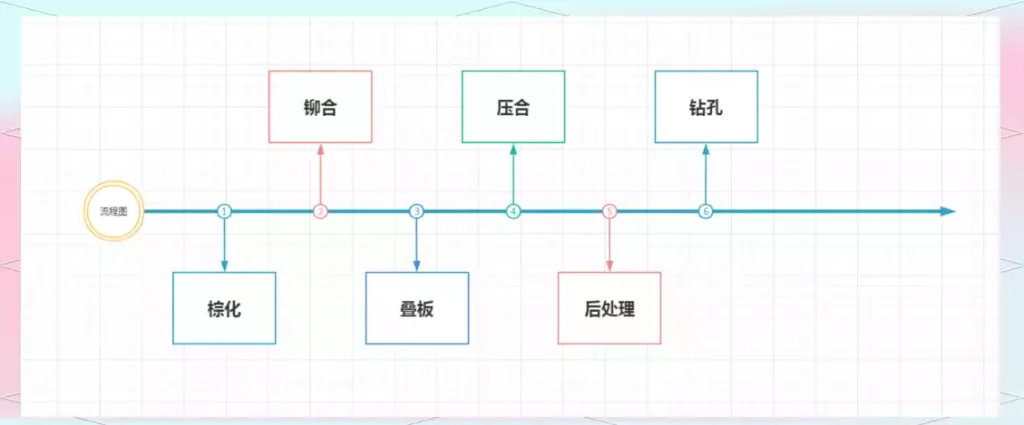

PCB board clamp production process and attention

- Design the shape and size of the pcb board clamp, according to the size of the circuit board to be processed, the design of the clamping jaws and positioning pins of the position and number.

- Select the appropriate material, generally use metal materials, such as aluminium alloy, stainless steel, etc., to ensure the strength and durability of the fixture.

- According to the design drawings, cutting, drilling and bending and other process operations on the material to produce the various components of the fixture.

- Assemble the parts of the fixture, including clamping jaws, positioning pins, springs, spanners and other parts.

- Carry out debugging and testing to ensure the clamping force and clamping stability of the fixture, as well as positioning accuracy and positional accuracy.

- When in use, pay attention to the maintenance and cleaning of the pcb board clamp, to avoid deformation or damage to the fixture, affecting the precision and quality of circuit board processing. At the same time, according to the use of the situation and the problems found in a timely manner to adjust and repair.

Maintenance of pcb board clamp

- Regularly check the failure of the cylinder, valve, standard parts and other components for replacement or repair.

- lubricate the cylinder to ensure that the cylinder liner and piston can be lubricated between the better operation and reduce friction loss.

- Clean and inspect the fixture regularly. The fixture is used with iron filings, oil stains, etc., which will affect the service life of the fixture if accumulated for a long time. Therefore, it is necessary to regularly clean and maintain the fixture.

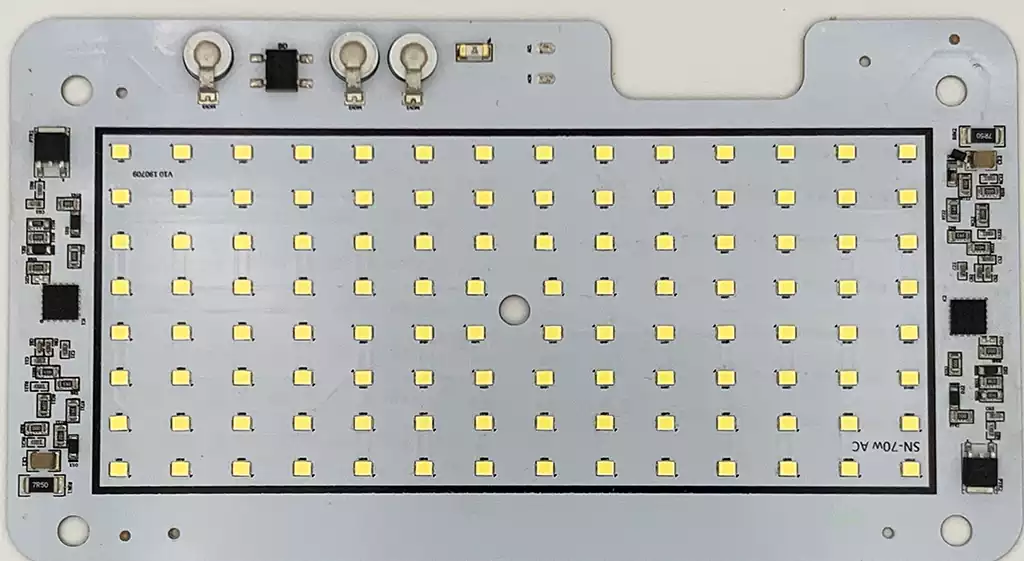

PCB board clamp plays a central role in the circuit board assembly and manufacturing process. They ensure operational stability and precision by fixing and positioning the circuit board. As demand for consumer electronics grows, the need for PCBs is also increasing rapidly, which has led to the widespread use of ultra-high-speed air spindles for microvia machining and highlighted the importance of fixtures in meeting the requirements for high-precision machining.