PCBA processing costs encompass multiple stages including PCB manufacturing, component procurement, SMT placement, DIP insertion, and testing/validation. Quotation efficiency is influenced by factors such as design file completeness, supply chain alignment, process complexity, batch size, and testing requirements. This article systematically outlines the cost components of PCBA and analyses key factors affecting quotation timeliness.

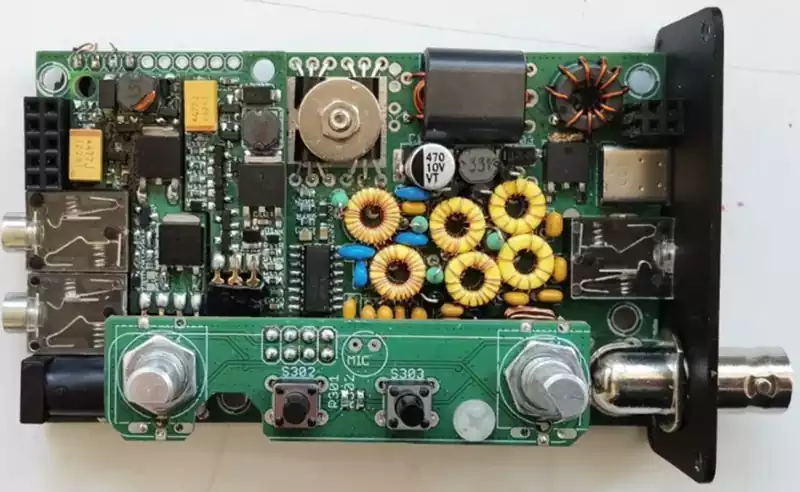

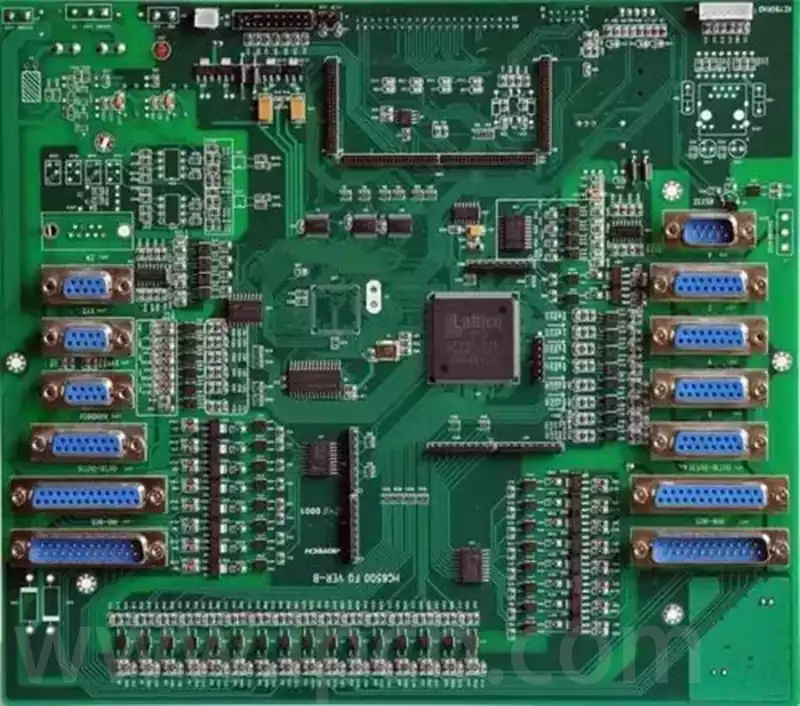

PCBA (Printed Circuit Board Assembly) costs constitute a multidimensional integrated system, primarily comprising the following major modules: PCB manufacturing costs encompass substrate material expenses and processing fees, influenced by board type, layer count, dimensions, and design complexity. Four-layer boards typically cost approximately double that of double-sided boards, while specialised process requirements (such as immersion gold plating) can significantly increase costs.

Component procurement costs include all electronic component acquisition expenses. Prices for standard resistors, capacitors, and similar components are transparent and stable. However, premium chips (e.g., BGAs, ICs) exhibit significant price volatility, potentially influenced by international embargoes or regulatory approval processes.

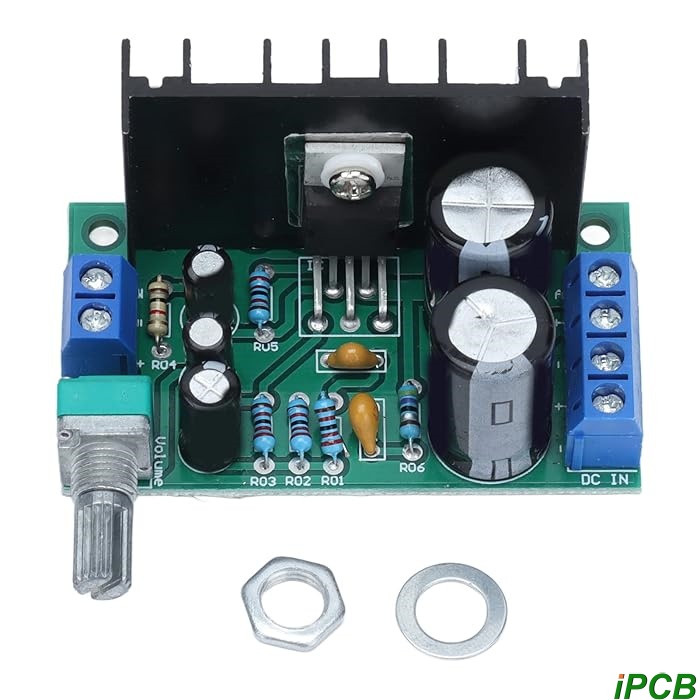

SMT assembly costs are calculated based on placement points. Industry practice typically counts standard SMD components (e.g., resistors, capacitors) as 2 points per piece. Medium-sized chips like QFPs are counted by pin count, while large chips such as BGAs are counted as 4-6 points.

DIP insertion processing costs are typically calculated per pin for insertion soldering, with unit prices differing between wave soldering and manual soldering. Testing and quality control costs encompass AOI (automated optical inspection), flying probe testing, functional testing, and other stages. Higher testing point counts incur greater costs.

Auxiliary materials and operational costs cover consumables such as solder paste, flux, stencils, packaging materials, alongside operational expenses including equipment depreciation, utilities, and management overheads.

Factors Influencing PCBA Quotation Speed

Design File Completeness and Standardisation

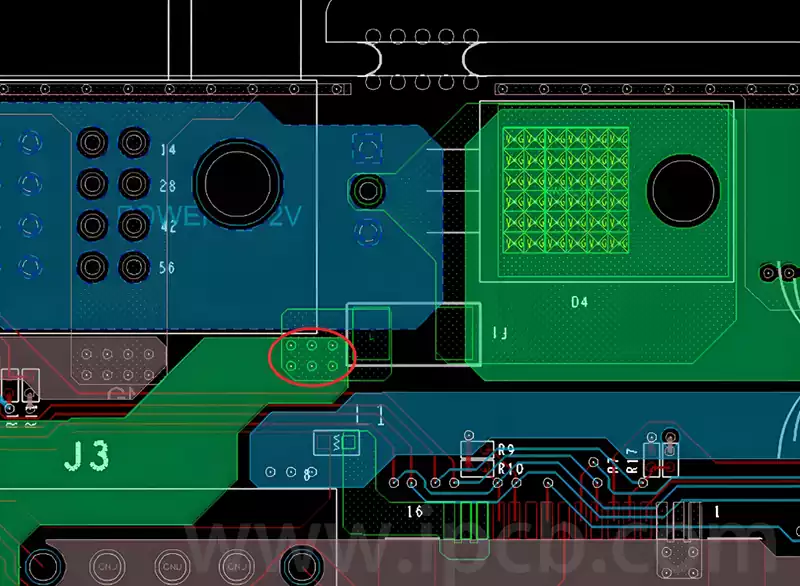

Complete Gerber files, BOM lists, and assembly drawings form the foundation for quotations. Missing files or non-standard formats (e.g., unclear component parameter annotations, mismatched packages) necessitate repeated engineer verification, prolonging the evaluation cycle. Adopting IPC-7351 standard package library design can reduce technical review time by over 30%.

Component Procurement Supply Chain Alignment

The lead times for specialised components (e.g., automotive-grade chips, high-precision sensors) directly impact quotation timelines. Leveraging our procurement network spanning over 300 global manufacturers, we deliver:

- Confirmation of stock availability and delivery schedules for standard components within 24 hours

- Alternative solutions for scarce materials within 48 hours

- Dedicated supply chain channels for custom components

Process Complexity Assessment Depth

Specialised process requirements (e.g., conformal coating application, selective soldering, X-ray inspection) necessitate labour-hour calculations based on production line equipment parameters. Our experienced engineering team employs DFM analysis to anticipate:

- Cost differences between double-sided and single-sided assembly

- Process costs for 0.4mm pitch BGAs versus standard packages

- Impact of different cleaning grades on equipment configuration

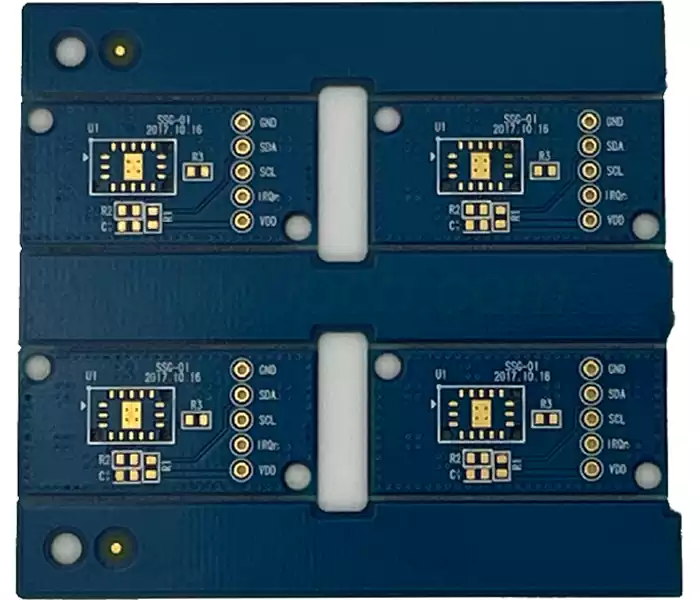

Batch scale and scheduling strategy

Quotation logic fundamentally differs between small-batch prototyping (<100pcs) and volume production (>1000pcs):

- Prototyping projects require comprehensive equipment setup costs

- Mass production projects prioritise long-term capacity utilisation

- Mixed orders require balancing SMT line change frequency with utilisation rates

Customisation Requirements for Test Verification Solutions

Inclusion of ICT/FCT testing, ageing tests, or environmental trials directly impacts quotation structure. We advise clients to clarify during the quotation phase:

- Functional test coverage requirements

- Environmental test items and standards

- Acceptance criteria for finished product yield rates

PCBA manufacturing costs are complex and variable. Furthermore, quoting efficiency is significantly influenced by key factors including: design document completeness, component supply chain alignment, depth of process complexity assessment, batch size and scheduling strategy, and customisation requirements for test and verification solutions.

Therefore, to achieve efficient and precise PCBA manufacturing collaboration, clients are advised to provide comprehensive design documentation during the quotation stage. This should include: Specification of specialised component requirements,detailed elaboration of process specifications and testing standards – Clear articulation of batch size Such documentation facilitates faster and more accurate cost evaluation and quotation by the manufacturing partner.