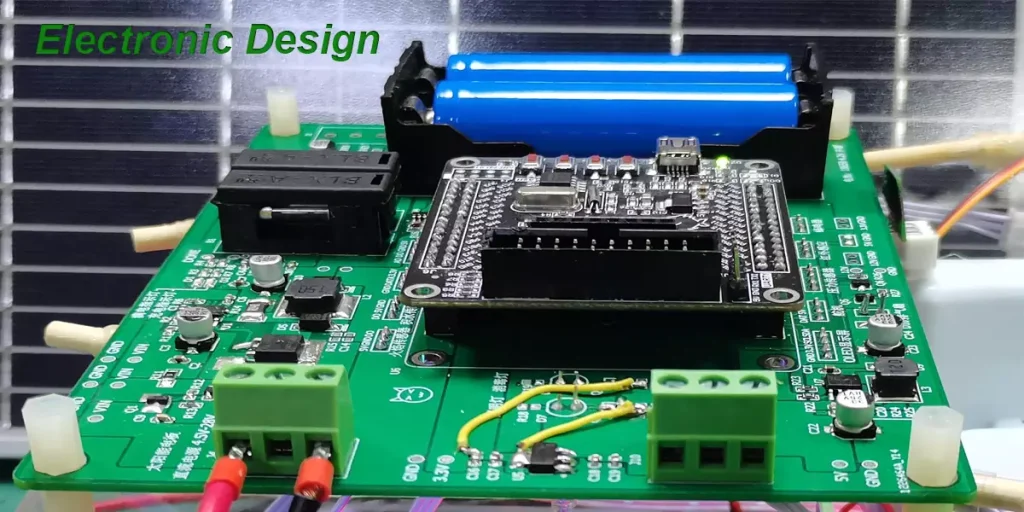

SMT stencils, commonly referred to as ‘templates’, are an indispensable component of the SMT (Surface Mount Technology) process; they serve as the template for printing solder paste onto the PCB (Printed Circuit Board) during the initial stage of surface mounting.

In the first stage of the SMT process, this smt stencil is employed to precisely print solder paste (a conductive adhesive) onto designated areas of the PCB (Printed Circuit Board).

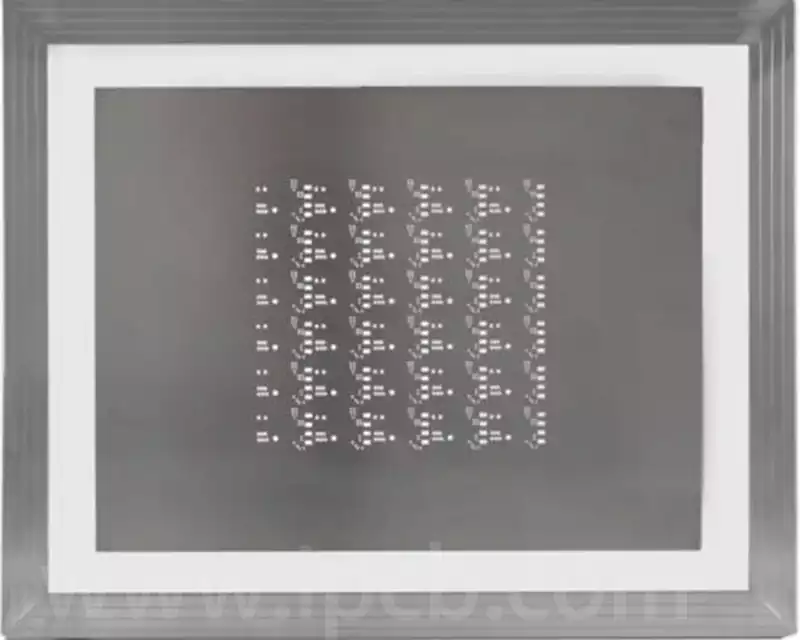

SMT stencils are primarily manufactured from stainless steel due to its excellent corrosion resistance, strength, and durability, making it highly suitable for SMT applications. The openings in the stencil (typically laser-cut or chemically etched) correspond precisely to the component pads on the PCB, ensuring accurate solder paste placement onto these pads.

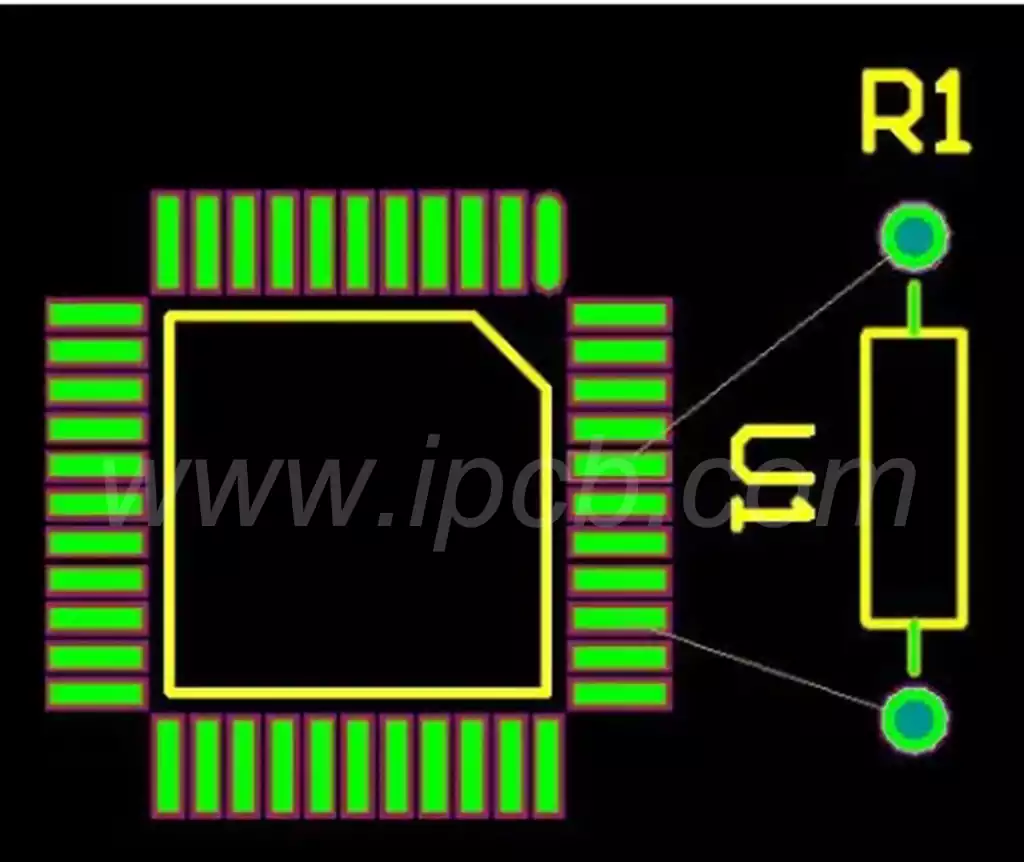

The design, manufacture, and utilisation of SMT stencils are critical to the success of the SMT process. Inadequate aperture design or poor manufacturing quality may result in substandard solder paste printing, thereby compromising the soldering quality of electronic components and the performance of the final product.

Common smt stencil fabrication techniques include laser cutting and etching, with laser cutting being the more prevalent method today.

Common stencil dimensions include: 37×47cm, 42×52cm, 55×65cm, 60×65cm, 65×65cm, 73.6×73.6cm, etc. Fully automated solder paste printers on standard SMT assembly production lines typically require a minimum stencil size of 42×52cm.

Common smt stencil classifications include: solder paste stencils, red glue stencils, stepped stencils, laser-cut stencils, dual-process stencils, etc. SMT stencil thicknesses typically include 0.8mm, 1.0mm, 1.2mm, 0.13mm, 0.15mm, 0.18mm, 0.2mm, 0.25mm, 0.3mm, etc. Solder paste stencils generally measure 0.05-0.15mm thick, while red glue stencils typically range from 0.18-0.3mm.

- Solder paste stencil: Solder paste stencils constitute the most extensively utilised type within SMT assembly facilities. The fabrication process for stencils is not fixed; aperture sizes are typically adjusted according to specific production requirements. Components requiring larger solder paste volumes are generally accommodated by enlarging pads and stencil apertures rather than increasing stencil thickness. This is because excessively thick solder paste stencils may cause processing defects such as short circuits in densely-packed ICs and similar components.

- Red Resist Stencils: With component miniaturisation, red resist stencils are gradually being phased out of SMT assembly production processes. Currently, they are primarily retained only for boards containing high-power components and CHIP devices, such as power supply boards.

- Stepped Stencils: Stepped stencils feature two or more distinct thicknesses on a single stencil plate. To accommodate varying solder paste requirements for different components and to handle all sizes of electronic parts appearing simultaneously on the same side of a circuit board while maintaining excellent soldering quality, it is often necessary to print different solder paste thicknesses on the same stencil. This enables precise control of solder volume, leading to the development of stepped stencils (i.e., STEP-UP for localised thickening and STEP-DOWN for localised thinning).

- Laser-cut stencils are primarily machine-driven, designed to transfer precise quantities of solder paste or red solder mask to corresponding positions on bare PCBs. Operators only need to design apertures and import/export files. The laser cutting machine then engraves the stencil according to the file, followed by polishing to enhance solder deposition efficiency. This method offers high speed and excellent quality.

Advantages:

(1) High precision. Both the positional accuracy and dimensional accuracy of the aperture positions on the template are guaranteed (error <3μm).

(2) Short processing cycle (data-driven).

(3) Controlled planning. Excellent quality consistency, independent of complex chemical formulations or process parameter adjustments for quantity control.

(4) Smooth aperture walls with surface roughness <3μm. Utilising beam focusing characteristics enables tapered apertures (narrower at top, wider at bottom), facilitating solder paste release. Controllable pad volume and shape application.

(5) No chemical solutions or processing required, eliminating environmental pollution. Disadvantages: Higher cost.

SMT Stencil Fabrication Materials

- Frame

Frames are categorised as movable or fixed. Movable frames directly mount the steel sheet onto the frame, allowing repeated use of a single frame. Fixed frames involve bonding the mesh fabric to the frame using adhesive, with the frame itself secured by adhesive. Fixed frames more readily achieve uniform steel sheet tension, typically ranging from 35 to 48 N/cm². (Permissible tension for standard fixed frames is 35–42 N).

Frame dimensions are determined by solder paste printer specifications. For example, the DEK265 and MPM UP3000 solder paste printers utilise 29×29-inch (735x735mm) frames constructed from aluminium alloy, with frame profiles measuring 1.5×1.5 inches. For semi-automatic solder paste printers, the frame dimensions are approximately 22 x 26 inches (560 x 650 mm). Standard stencil sizes: (CM) 20 x 30, 30 x 40, 37 x 47, 42 x 52, 50 x 60, 55 x 65, 23″ x 23″, 29″ x 29″. Common thicknesses: (MM) 0.05 (rarely used) 0.08 (rarely used) 0.10 0.12 0.13 0.15 0.18 0.20……

- Mesh

Mesh is employed to secure steel sheets and frames, categorised into stainless steel wire mesh and high-molecular polyester mesh. Stainless steel wire mesh typically utilises approximately 100 mesh, providing stable and adequate tension; however, prolonged use may cause deformation and loss of tension. Polyester mesh, often employing 100 mesh, exhibits resistance to deformation and extended service life. - Template Material

Selection of SMT stencils template material must consider inherent factors such as rigidity, corrosion resistance, ductility, and thermal expansion coefficient, as these directly impact template longevity (corrosion, warping, and aperture deformation). Common materials include tin-phosphorus bronze, stainless steel, and nickel-chromium alloys, with stainless steel being the most prevalent. This encompasses copper, stainless steel, nickel alloys, and polyester materials. Templates typically employ premium imported 301/304 stainless steel sheets, whose superior mechanical properties significantly extend service life. - Adhesive

The adhesive bonding the stencil frame to the steel sheet plays a critical role in the template. Customised formulations may be employed to suit specific client requirements, ensuring robust adhesion while withstanding complex cleaning agents used for template maintenance.

The primary function of SMT stencils lies in the precise printing of solder paste or red solder paste onto the pad areas of electronic components on PCBs. Their aperture design corresponds one-to-one with PCB pads, and through precision manufacturing processes, ensures high accuracy and consistency in printing. During operation, the stencil is positioned atop the PCB. The operator then employs tools such as a squeegee to uniformly dispense solder paste or red glue through the stencil apertures onto the PCB pads. Rigorous control of this step is paramount for ensuring printing uniformity and consistency, which directly impacts the soldering quality of electronic components and the performance of the final product. The SMT stencil holds an indispensable position within the SMT placement process, serving as a critical tool for safeguarding soldering quality and product performance.