In the field of pcb board manufacturing, the precision and stability of processes directly impact product quality and performance. From substrate pre-treatment to the lamination and forming of multilayer boards, through to the fabrication of special structures such as step grooves and the control of board warpage, each stage involves intricate technical considerations and rigorous operational protocols. The following details key process stages in PCB board manufacturing alongside corresponding considerations, aiming to provide comprehensive and practical guidance for enhancing PCB board production quality.

Conduct dimensional pre-placement for each core board based on material type, residual copper content, and lamination parameters (collect dimensional data for each product to establish an expansion/contraction database for future reference). Employ PIN-LAM or MASS-LAM positioning methods to sequentially stack and secure core boards, prepregs, and copper foil according to the product’s laminate structure, followed by initial trial production. Test the interlayer alignment accuracy of the first-article sample (via X-ray or cross-section analysis). Adjust the core board pre-placement values based on test results before commencing formal production.

Following lamination, test the expansion/contraction of inner layer patterns. Subsequently scale the CNC drilling programme and proceed with drilling. Expansion/contraction test patterns should be symmetrically distributed relative to the board centre, positioned as far as possible from pins or rivets, and as close as feasible to the actual production layout. For oversized boards, divide the surface into zones, arranging one set of test patterns per zone for zoned expansion/contraction drilling.

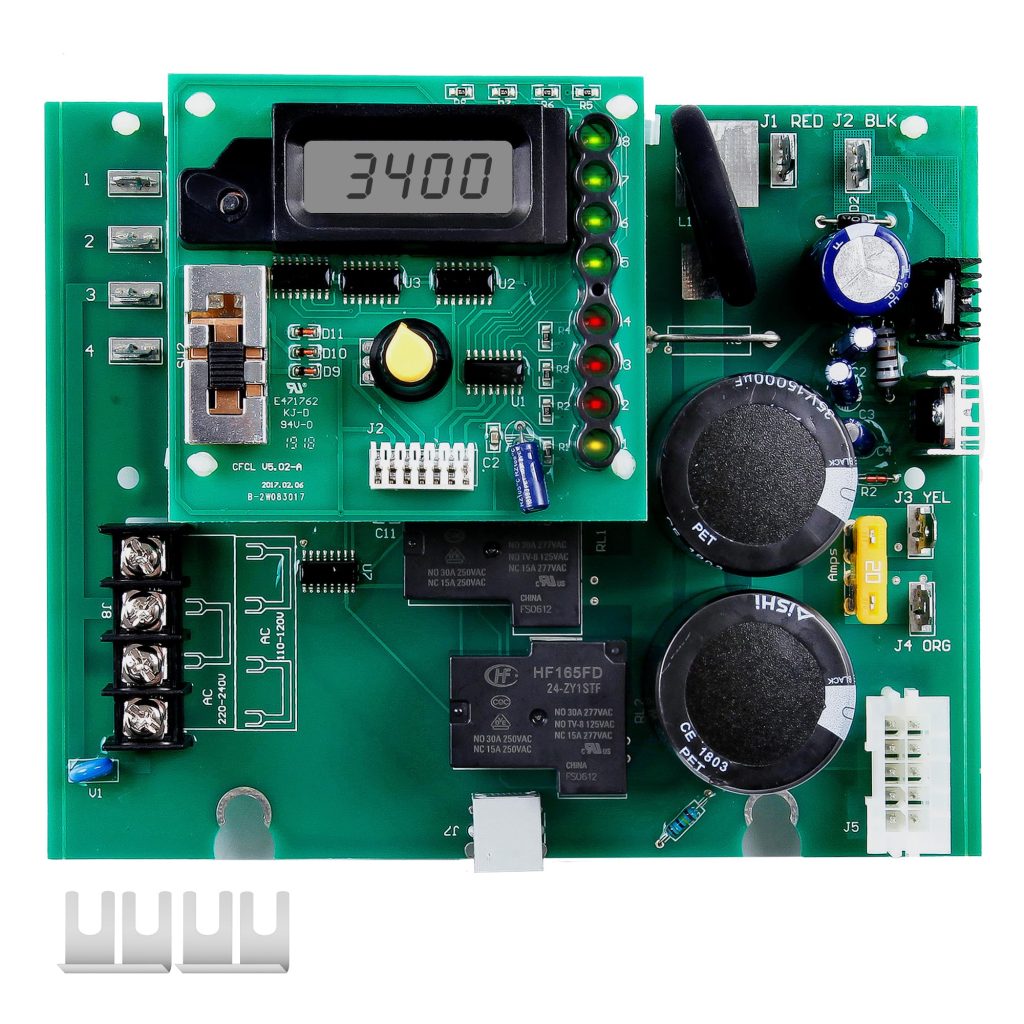

To reduce component mounting surfaces, provide positioning guides, or lower stacking heights, stepped grooves of varying sizes and depths may be distributed along PCB board edges or within the board. Figure 1 illustrates two common types: grooves with metal at the base or sides (left), and grooves with metal at both base and sides forming a continuous structure.

The two most common methods for creating stepped grooves are the filled shim method and reverse milling of the core board.

Shim Filling Method: Windows are cut in the prepreg adjacent to the blind slot bottom. During lamination, shims of similar thickness are inserted into these windows. Prior to surface plating, the shims are removed by controlled-depth milling (with precision < prepreg thickness). This method provides excellent resin barrier performance, resulting in minimal resin overflow at the blind slot bottom and high dimensional accuracy. However, inserting and removing shims demands considerable labour hours. Smaller shims are prone to curling, exhibit pronounced electrostatic adhesion, and carry significant displacement risks.

Reverse Milling Core Board Method: Open a window in the prepreg adjacent to the blind slot bottom. Reverse-mill approximately two-thirds of the core board thickness, then proceed with lamination and pressing. Prior to surface coating, the shim is accessed and removed via depth-controlled milling (depth control accuracy < core board thickness). This method is straightforward to operate but yields relatively lower blind slot dimensional accuracy, with prepreg material potentially overflowing into the reverse-milled toolpath. Additionally, if the core board exhibits low strength (e.g., PTFE resin systems without glass fabric reinforcement), bulging may occur at the blind slot bottom corresponding to the reverse milling path. Therefore, it is recommended to use a smaller diameter tool (D ≤ 0.5mm) for core board reverse milling (laser cutting may also be employed, typically with a spot path < 0.3mm).

Panel warpage adversely affects component assembly yield rates, particularly for lead-free soldering of multi-pin, large-sized components such as FCBGAs (Flipchip Ball Grid Arrays), LGAs (Land Grid Arrays), and CCGAs (Ceramic Column Grid Arrays). Due to environmental regulations, lead-free soldering is progressively replacing leaded soldering. As lead-free soldering temperatures are typically 30°C higher than leaded soldering, it imposes stricter thermal resistance requirements on materials. To minimise warpage during high-temperature soldering, core boards with a high glass transition temperature (Tg ≥ 170°C) should be selected. Furthermore, panel warpage arises from uneven stress distribution at elevated temperatures. Consequently, the multilayer board stack-up should be as symmetrical as possible, with copper plating applied to unrouted blank areas. Where pcb boards incorporate predominantly polyester-based materials such as PTFE, PPO, or FR4, and the laminate structure is asymmetrical, inserting a thick metal core layer (e.g., copper, copper-indium-copper, copper-molybdenum-copper) within the board may mitigate warpage.

Delamination, blistering, voids, and other defects within multilayer pcb boards are largely directly related to the lamination process.

The lamination process is critical to the quality of multilayer pcb boards. If not handled properly, issues such as delamination and blistering can easily occur. The following precautions will help ensure a successful lamination process and reduce product defects:

a) Regularly test the parallelism and temperature uniformity of the press hot plates. Should any abnormalities arise, promptly contact the manufacturer for equipment maintenance.

b) Clean residual adhesive from the pressing moulds and cutting steel plates at the end of each shift to prevent pitting or indentations on the board surface caused by falling residue.

c) Select appropriate shim thickness, maintaining a thickness difference of no more than 30 microns between the shims and the windowed prepreg sheets. Replace pressure-absorbing materials regularly.

d) Ensure the residual copper rate on the core board matches the resin content in the prepreg sheets to prevent insufficient resin filling.

e) Ensure uniform colouration of copper foil surfaces on browned or blackened core boards, with micro-etching levels meeting specifications.

PCB board manufacturing demands exceptional precision and technical expertise. Only through rigorous control of process parameters and operational standards at every stage, coupled with continuous production optimisation, can PCB quality and reliability be effectively enhanced. This approach satisfies increasingly stringent market requirements and secures a competitive edge within the fiercely contested electronics manufacturing sector.