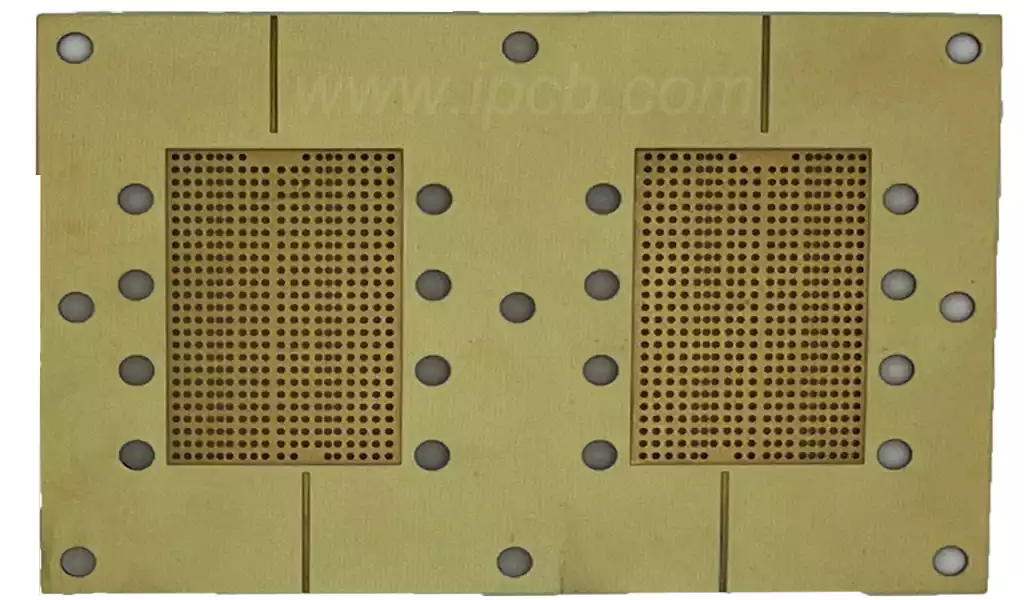

Double sided SMT assembly refers to the placement of components on both sides of a PCB. This technique maximises the utilisation of the circuit board’s available space, enabling more complex and compact designs. It represents an advancement over single-sided assembly, which involves mounting components on only one side of the PCB.

The core of double sided SMT assembly lies in utilising Surface Mount Technology (SMT) to precisely place electronic components on both sides of the Printed Circuit Board (PCB). Electrical and mechanical connections are achieved through thermal reflow soldering. This process requires precision equipment and process control to ensure stable soldering on both sides, preventing short circuits or open circuits, ultimately achieving high integration and functionality in the circuit board.

Advantages of double sided SMT Assembly

Space Efficiency

A primary advantage of double sided SMT assembly lies in its space efficiency. By fully utilising both sides of the PCB, manufacturers can accommodate more components on a smaller circuit board. This proves particularly crucial in compact device designs where space constraints are paramount, such as smartphones, tablets, and wearable devices.

Cost Efficiency

The adoption of double sided PCBs effectively reduces costs. By downsizing the circuit board dimensions, manufacturers can minimise material consumption. Furthermore, the capacity of a single board to carry more components means fewer boards are required for complex circuits, further lowering expenses.

Enhanced Functionality

Double sided SMT assembly supports more intricate circuit designs. The ample space allows designers to incorporate additional features into products, offering significant benefits for industries demanding advanced functionality, such as consumer electronics, automotive, and medical devices.

Performance Enhancement

The double sided layout permits component distribution across both sides of the board, thereby optimising performance. Through strategic component placement, designers can effectively minimise signal interference and enhance circuit reliability. For high-performance applications, these subtle improvements often yield significant advantages.

Challenges and Considerations

Complex Design Process

Designing double sided PCBs is more intricate than single-sided circuit boards. Engineers must meticulously plan component placement to avoid interference and ensure reliable connections. This necessitates advanced design software and specialised expertise. Manufacturing Challenges Producing double sided PCBs presents greater manufacturing challenges than single-sided boards. The process demands precise alignment and soldering, with heightened risks of defects. Manufacturers must invest in specialised equipment and quality control procedures to guarantee finished product quality. Increased Time and Resource Consumption The complexity of double sided SMT assembly may lead to extended production cycles and heightened resource requirements. Manufacturers must balance the advantages of double sided assembly against the potential risks of increased costs and extended production cycles.

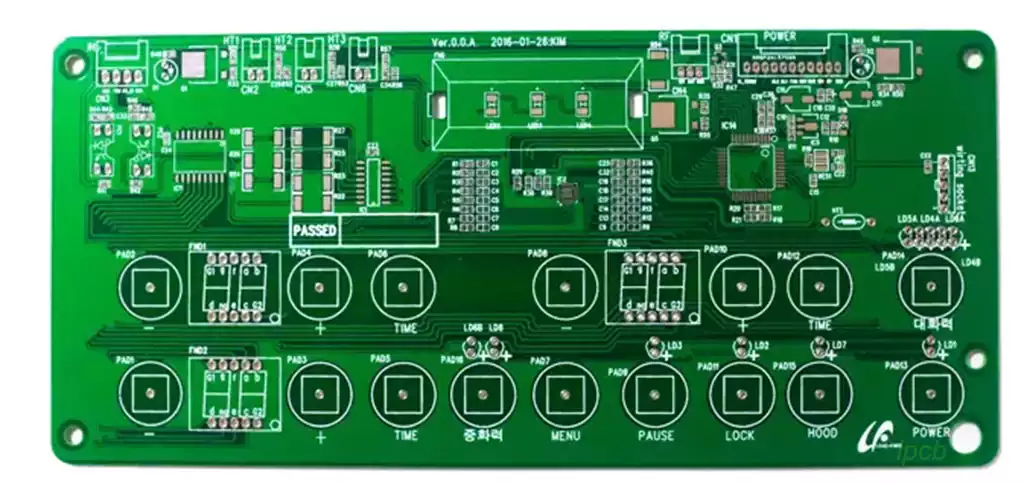

Applications of double sided SMT Assembly

Double sided SMT assembly technology finds extensive application across multiple industrial sectors.

Consumer Electronics

Within consumer electronics, demand for smaller yet more powerful devices drives the adoption of double sided SMT assembly. Smartphones, tablets, and wearable devices all benefit from the space-saving advantages this technology offers.

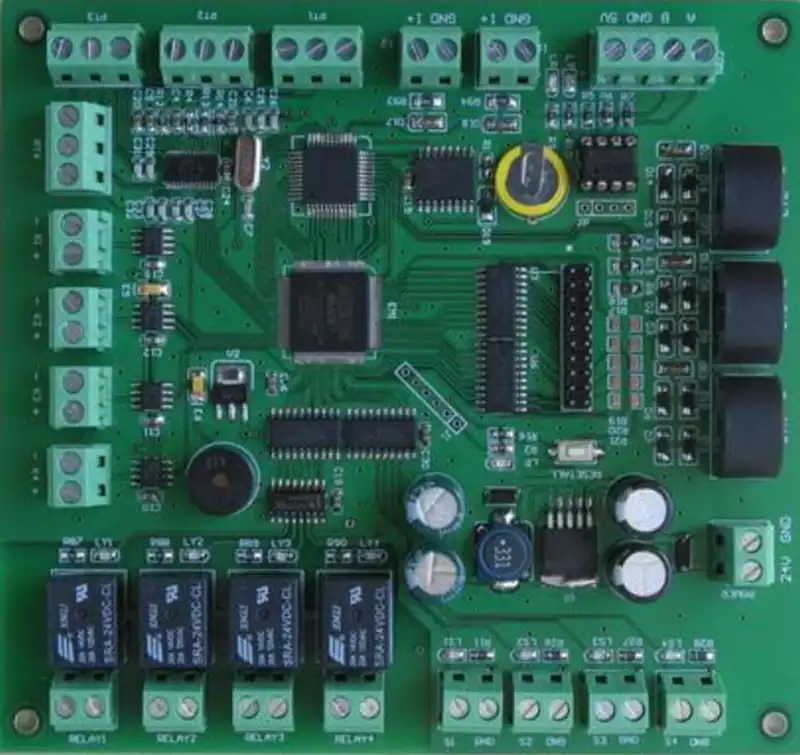

Automotive Industry

The automotive sector employs double sided SMT assembly to manufacture advanced electronic systems such as infotainment units, Advanced Driver Assistance Systems (ADAS), and Engine Control Units (ECUs). These systems rely on compact, reliable circuit boards for efficient operation.

Medical Devices

Medical equipment including portable diagnostic devices and wearable health monitors requires compact, dependable electronic components. double sided SMT assembly enables manufacturers to meet these demands while integrating advanced functionalities.

Future Trends in double sided SMT Assembly

As technology advances, PCB assembly techniques will continue to evolve.

Miniaturisation Trend

The ongoing miniaturisation of electronic devices will drive widespread adoption of double sided SMT assembly. With components becoming smaller yet more powerful, the demand for efficient space utilisation will grow significantly.

Material Technology Innovations

Advancements in materials and manufacturing processes will enhance the accessibility and cost-effectiveness of double sided SMT assembly. Novel materials such as flexible substrates and advanced soldering techniques will further elevate the functional performance of double sided PCBs.

Integration of Artificial Intelligence and Automation

The convergence of artificial intelligence (AI) and automation within manufacturing processes will significantly boost the efficiency and precision of double sided SMT assembly. These technologies will assist manufacturers in overcoming process challenges, reducing defects, and shortening production cycles.

As a powerful technology, double sided SMT assembly offers numerous advantages for modern electronics manufacturing. By maximising space utilisation and supporting more complex designs, it enables manufacturers to create smaller, more powerful devices. Although the technology itself presents challenges, advances in techniques and manufacturing processes are making it an increasingly viable option across a broad range of applications. With the sustained growth in demand for compact, advanced electronic devices, double sided SMT assembly will play a crucial role in meeting these requirements.