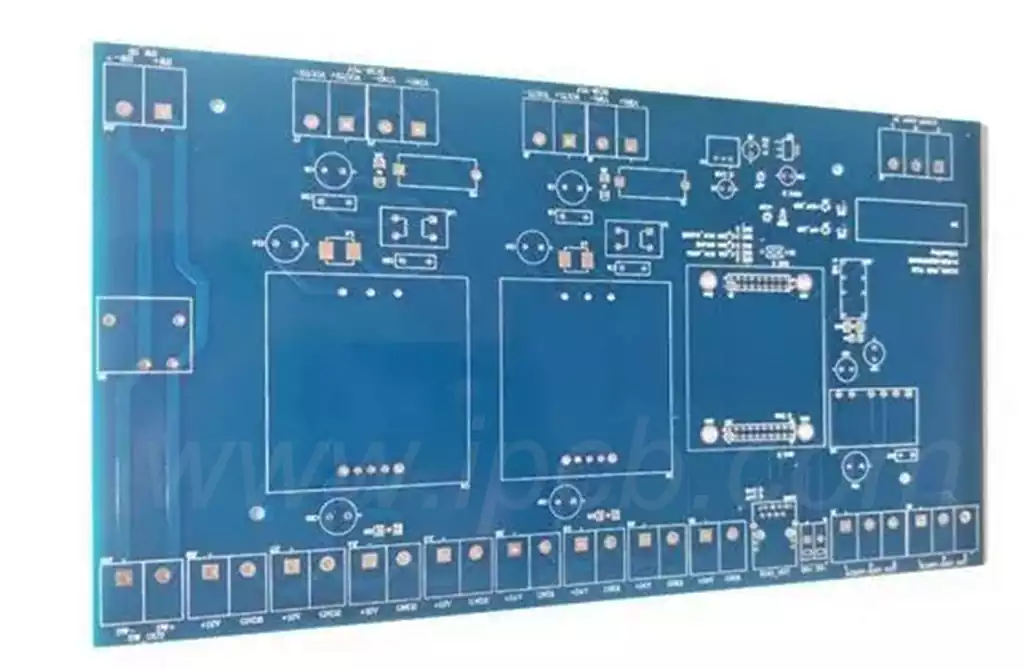

SMD led pcb board typically refer to circuit carriers employing SMT technology, whereby LED chips and associated electronic components are directly soldered onto the surface of a PCB board. Compared to traditional through-hole circuit boards, this structure eliminates the need for drilling holes to mount components, thereby saving space and enabling higher-density circuit layouts.

Core Characteristics of SMD LED PCB boards

Compact Design

Pinless Construction: SMD LEDs employ flat packaging (e.g., ‘seagull wing’ leads) for direct surface mounting on PCB boards, eliminating drilling or through-hole installation and saving the pin space required for traditional through-hole LEDs.

High-density integration: Supports single- or double-sided mounting, enabling greater LED component density within limited areas. Ideal for miniaturised lighting applications (e.g., smartwatch backlights, mobile phone flashlights) or high-resolution displays.

Efficient thermal management

Metal substrate application: Commonly employs aluminium or copper substrates as pcb materials. The metallic layer rapidly dissipates heat generated by LEDs, reducing junction temperatures and extending service life.

Thermal Conductivity Optimisation: Internal pcb thermal pathways (e.g., thermal vias, heat sinks) enhance dissipation efficiency for high-power LED lighting (e.g., stage lights, automotive headlamps).

Flexibility and Customisability

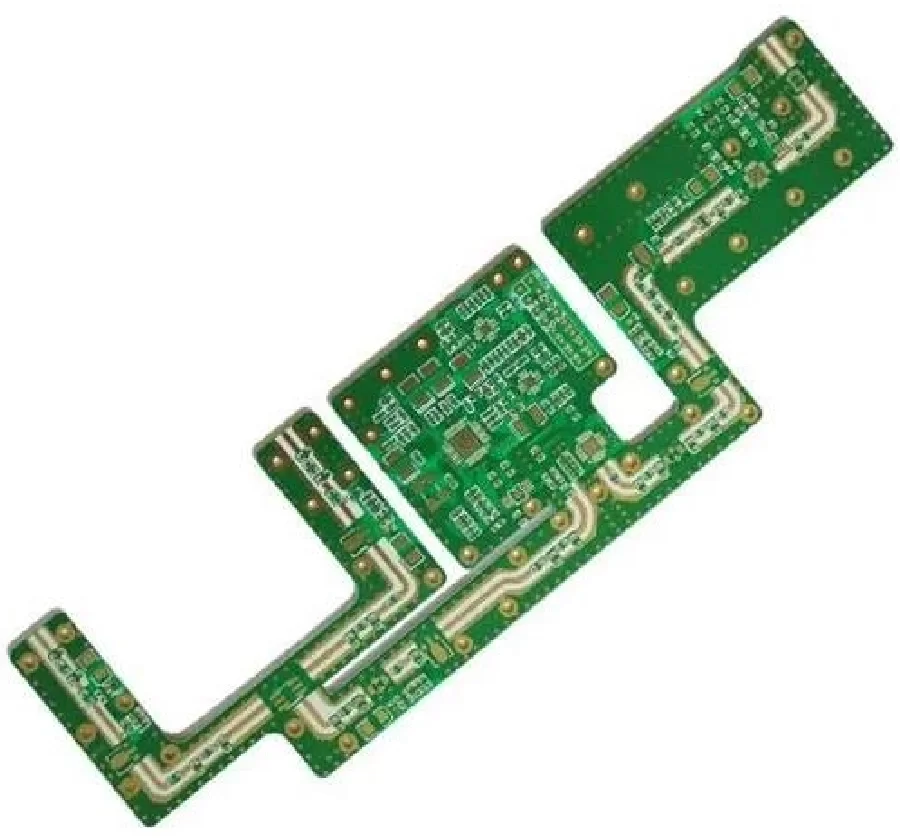

Flexible substrate support: Utilises flexible materials like polyimide (PI) to bend into arcs or irregular shapes, meeting creative lighting design requirements (e.g., column wraps, curved light strips).

Multi-colour combinations: Supports RGB tri-colour LED placement, enabling dynamic colour changes via circuit control. Widely applied in signage, decorative lighting, and similar fields.

Automated Production Compatibility

SMT Process Adaptation: Fully compatible with automated equipment including high-speed pick-and-place machines and reflow ovens, enabling large-scale, high-precision production while reducing labour costs.

Standardised Workflow: End-to-end monitoring from solder paste printing to testing ensures product consistency.

Significant Advantages

Performance Enhancement

High luminous efficacy: Compact design minimises light loss, while high-reflectivity PCB materials (such as white solder mask) enhance light output uniformity.

Extended Lifespan: Superior thermal management slows LED lumen depreciation, delivering typical lifespans exceeding 50,000 hours—far surpassing conventional lighting.

Enhanced Vibration Resistance: Lead-free soldered structures offer greater stability than through-hole components, making them suitable for vibration-prone environments (e.g., automotive and aviation lighting).

Cost Optimisation

Reduced material costs: Whilst metal substrates like aluminium carry higher unit costs, overall competitiveness is achieved through minimising auxiliary heat dissipation components (e.g., heat sinks).

Enhanced production efficiency: Automated manufacturing shortens lead times and reduces manual intervention, making it ideal for mass production (e.g., LED strips, display backlight modules).

Environmental sustainability and energy efficiency

Low-power design: The inherent high energy efficiency of LEDs, combined with optimised PCB circuit layout, further reduces energy consumption.

Mercury-Free Pollution: Unlike traditional fluorescent lamps, SMD LED PCB boards contain no mercury or other hazardous substances, meeting environmental standards.

Application Areas of SMD LED PCB boards

Consumer Electronics

In the consumer electronics sector, where compactness and performance demands are paramount, SMD LED PCB boards are frequently employed in smartphones, laptops, and televisions. Their miniature dimensions and high efficiency make them an ideal choice for these applications.

Automotive Lighting

The automotive industry benefits significantly from SMD LED PCB boards. Their exceptional durability and resistance to harsh environments make them widely adopted in headlights, tail lights, and interior lighting systems.

Industrial Equipment

Within industrial settings, SMD LED PCB boards are employed in machinery requiring reliable, high-efficiency lighting solutions. Their robust design renders them suitable for demanding operational conditions.

Despite numerous advantages, several challenges warrant consideration. The complexity of design and assembly processes demands high-precision operations and specialised expertise, with initial configuration costs being elevated due to the requirement for dedicated equipment.

Design and Assembly Precision

The design and assembly of SMD LED PCB boards necessitate exceptional accuracy, requiring manufacturers to employ skilled technicians and advanced machinery. Ensuring precision in component placement and soldering is critical to the performance and reliability of the boards.

Initial Investment

While SMD LED PCB boards offer significant long-term benefits and cost savings, the initial investment in technology and equipment remains a barrier for some manufacturers. However, these costs are steadily decreasing as demand grows and technology advances.

The Future of SMD LED PCB Boards

With ongoing technological progress, the outlook for surface mount LED circuit boards is highly promising. Continuous improvements in materials and manufacturing processes are enhancing the efficiency and cost-effectiveness of these boards. Driven by industry-wide demand for more compact and powerful electronic products, market requirements for surface-mount LED circuit boards are poised for sustained growth.

SMD LED PCB boards stand as an exceptional choice across diverse applications due to their multiple advantages. Their compact design, outstanding performance, and cost-effectiveness make them an ideal solution for enhancing LED circuit board systems. Whether in consumer electronics, automotive manufacturing, or industrial sectors, these boards deliver the flexibility and efficiency required to meet modern technological demands.