PCB board to wire connectors (also known as wire-to-board connectors) are used to connect wires to printed circuit boards. These connectors are present in virtually all electronic devices, serving as critical components that establish the necessary electrical connections between the circuit board and other components. They typically comprise two parts: one is the connector terminal mounted on the circuit board, while the other is the connector plug or terminal that connects to external cables.

Primary Functions of PCB board to wire connectors

Electrical Transmission:

The core function of connectors is to transmit electrical signals and power. They ensure the smooth transfer of data, control signals, or current between the circuit board and external devices.

Mechanical Connection:

PCB board to wire connectors provide not only electrical but also mechanical connections, ensuring cables are securely attached to the circuit board and preventing poor contact due to vibration or pulling.

Signal Protection:

High-quality PCB board to wire connectors effectively shield against external interference and noise, particularly in high-frequency, high-speed signal transmission applications.

Simplified Assembly and Maintenance:

Connectors facilitate easier device assembly and servicing. Maintenance personnel can readily remove or replace faulty components by disconnecting the connector, bypassing complex soldering procedures.

Common Types of pcb board to wire connectors

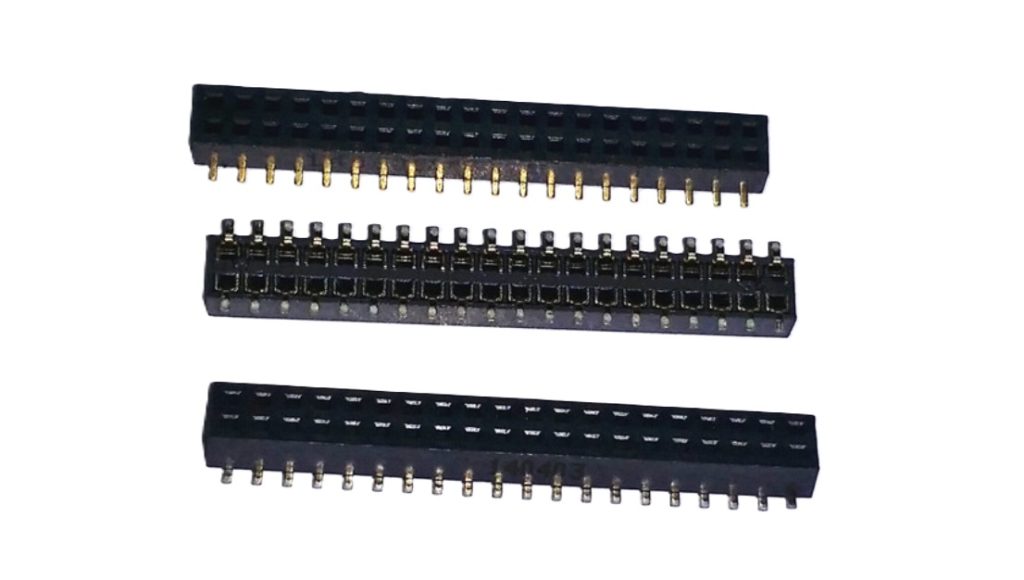

Crimp Connectors:

Crimp connectors typically comprise a plug and socket, securing wires to the connector terminals via crimping. They prove highly useful in applications requiring frequent connection and disconnection, such as automotive electronics and consumer electronics.

Through-Hole Connectors:

Through-hole connectors represent one of the most prevalent types of pcb board to wire connectors. They secure wires by passing pins through PCB holes, with electrical connections established via soldering. These connectors are typically employed in high-current, low-frequency applications.

Surface-mount connectors:

These connectors are soldered directly to the PCB surface, eliminating the need for through-hole pins. They are well-suited for high-density PCBs and space-constrained designs. Surface-mount connectors are extensively employed in modern consumer electronics such as smartphones and laptops.

Push-in connectors:

Push-in connectors utilise an automatic locking mechanism for rapid connection without requiring screws or crimping tools. They are suitable for applications demanding high reliability and quick installation, such as domestic appliances and industrial control equipment.

FPC/FFC connectors (Flexible Printed Circuit/Flexible Flat Cable connectors):

FPC/FFC connectors link flexible printed circuits (FPC) or flexible flat cables (FFC) to fixed circuit boards. They are suitable for applications requiring flexibility, such as portable devices and consumer electronics.

Primary application areas for PCB board to wire connectors:

1.Consumer Electronics

Consumer electronics such as smartphones, tablets, laptops, televisions, and household appliances universally rely on PCB board to wire connectors to link circuit boards with external components (e.g., batteries, displays, audio systems). These devices demand compact and efficient connection solutions, hence surface-mount device (SMD) connectors and miniature plug-in connectors are extensively utilised in such products.

Smartphones: Connectors link components including batteries, camera modules, and displays.

Laptops: Used for connecting displays, power supplies, USB ports, etc.

Home Appliances: Examples include washing machines and microwaves, connecting control boards to motors or heating elements.

2.Automotive Electronics

With the ongoing advancement of automotive intelligence, autonomous driving, and electrification, PCB board to wire connectors have become particularly crucial in automotive electronics. They connect the vehicle’s electronic control units (ECUs), sensors, actuators, displays, lighting systems, and more. Automotive electronic systems typically require highly reliable connectors to withstand high temperatures, vibrations, and harsh environmental conditions.

In-vehicle electronic systems: Such as infotainment systems, navigation systems, reversing camera systems, airbag control modules, etc.

Electric vehicles: Connections between components like the battery management system (BMS), charge control, and motor control units.

Autonomous driving technology: Connections for sensors including radar, LiDAR, and cameras.

3.Industrial Automation

Within industrial automation, PCB board to wire connectors are extensively employed in PLCs (Programmable Logic Controllers), robots, sensors, actuators, and control boards for industrial equipment. These connectors provide stable, reliable electrical connections to ensure equipment operates correctly under high loads and prolonged operation.

Robotic Control Systems: Used for connecting robotic sensors, servo motors, control boards, and similar components.

PLC Control Systems: Employed for automated control within industrial equipment, ensuring reliable connections between sensors, actuators, and circuit boards.

Motor Control Systems: Facilitating efficient power transmission between electric motors and control circuits.

4.Communication Equipment

PCB board to wire connectors also find extensive application within communication devices. They connect base station equipment, switches, routers, signal processing units, and similar components to guarantee stable transmission of data, voice, or video signals. Performance is particularly critical in high-speed communication equipment such as 5G base stations and fibre optic communication devices.

Base Station Equipment: Connects antennas, signal processors, power systems, and other components.

Routers and Switches: Connects the mainboard to other modules (e.g., network ports, power supply modules).

Fibre optic communication equipment: Used to connect fibre optic modules, converters, signal amplifiers, etc.

5.Medical Electronics

Within medical electronic devices, PCB board to wire connectors play an exceptionally vital role, particularly in equipment demanding the highest levels of reliability and safety. For instance, patient monitors, medical imaging equipment, artificial implants, and laboratory apparatus all require precise and highly reliable electrical connections.

Monitoring equipment: Connects various sensors, probes, displays, and alarm systems.

Imaging equipment: Such as CT and MRI scanners, connecting internal sensors, display units, and computer systems.

Portable medical devices: Including portable blood glucose monitors and electrocardiographs, used to connect batteries, displays, sensors, and other components.

6.Aerospace and Defence

The aerospace and defence sectors impose exceptionally stringent requirements on electronic connectors. Beyond providing stable electrical connections, these connectors must operate reliably under harsh conditions including high temperatures, humidity, and severe vibration. Such connectors are predominantly used in aircraft, satellites, radar systems, and military communications equipment.

Satellites and Spacecraft: Connecting various internal electronic modules such as sensors, communication devices, and control units.

Military Equipment: Connecting components in communication systems, radars, navigation systems, and similar military hardware.

Aircraft: Facilitating electrical connections within avionics to ensure seamless communication between flight control systems, navigation systems, power systems, and other critical subsystems.

7.Energy and Power

Within the energy and power sector, PCB board to wire connectors are employed for the control, monitoring, and management of electrical systems. They find extensive application in power substations, wind power generation, solar power generation, electric vehicle charging points, and other domains, ensuring the stable operation and efficient control of power systems.

Solar power generation systems: Connecting photovoltaic panels, inverters, battery management systems, etc.

Power control systems: Used for electrical equipment connections in power plants and substations.

Electric Vehicle Charging Infrastructure: Connecting power lines, control modules, and charging interfaces.

8.Smart Home Technology

With the advancement of smart homes, PCB board to wire connectors play a vital role in home automation devices. These include smart lighting, security systems, thermostats, and voice assistants, where connectors provide stable electrical connections to ensure seamless operation of smart home systems.

Smart Home Devices: Connecting components such as smart bulbs, smart sockets, and smart door locks.

Home Security Systems: Used to connect sensors, cameras, alarms, and other modules.

Smart Temperature Control Systems: Connections for devices such as smart air conditioning and heating controls.

Selecting Suitable PCB board to wire connectors

Current and Voltage Requirements:

The current and voltage ratings of the connector must align with the PCB’s design specifications. For high-current, high-voltage applications, selecting a connector with sufficient load capacity is crucial.

Signal Frequency and Bandwidth:

For high-speed signal transmission, the connector design should support high-frequency signals and offer robust interference resistance. Commonly used connectors in such scenarios include coaxial connectors and differential signal connectors.

Dimensions and Space:

In space-constrained designs, compact connectors are particularly important. Surface-mount connectors and micro connectors are typically suitable for these situations.

Durability and Environmental Adaptability:

In harsh environments (such as high temperatures, humidity, or vibration), connector durability is paramount. Selecting connectors compliant with IP ratings or featuring vibration-resistant designs enhances system reliability.

Mounting Methods:

Connectors offer various mounting options including through-hole, surface-mount, and quick-release. Choosing connector types compatible with production line assembly processes improves efficiency and reduces error rates.

Connection Methods:

Depending on application requirements, select different connection methods such as crimping, plug-in, or soldering to ensure stable electrical connections and maintainability.

PCB board to wire connectors play a vital role across various industries. These connectors provide stable and reliable electrical connections for electronic systems, ensuring the normal operation and efficient functioning of equipment. As technology continues to advance, demands on connectors grow increasingly stringent. Selecting the appropriate connector not only enhances system performance but also improves product reliability and longevity.