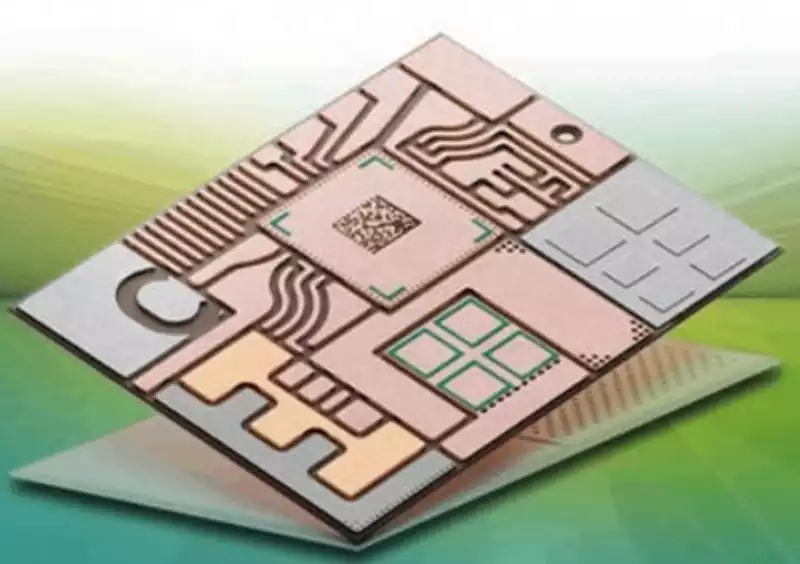

In the manufacturing process of multilayer ceramic pcb, lamination is not merely a straightforward step of ‘stacking and applying pressure’. As the number of layers increases, circuit density rises, and substrate dimensions expand, the differing responses of each layer’s materials under stress and thermal conditions become progressively amplified. Minor displacements that might be negligible in single-layer or low-layer structures often manifest as significant circuit misalignment, hole offset, or overall warpage within multilayer configurations. Consequently, lamination has progressively become one of the most sensitive and challenging processes to stabilise in multilayer ceramic PCB manufacturing. Effectively suppressing interlayer displacement and structural deformation during this stage has thus emerged as a critical issue requiring direct attention in process design.

Analysis of Primary Causes of Pressing Displacement and Deformation

During multilayer ceramic PCB pressing, displacement and deformation are not incidental defects but result from the combined effects of multiple material properties and process conditions. Only through thorough deconstruction of their formation mechanisms can targeted control be achieved in subsequent process design.

1.Mismatch in Material Mechanical and Thermal Properties

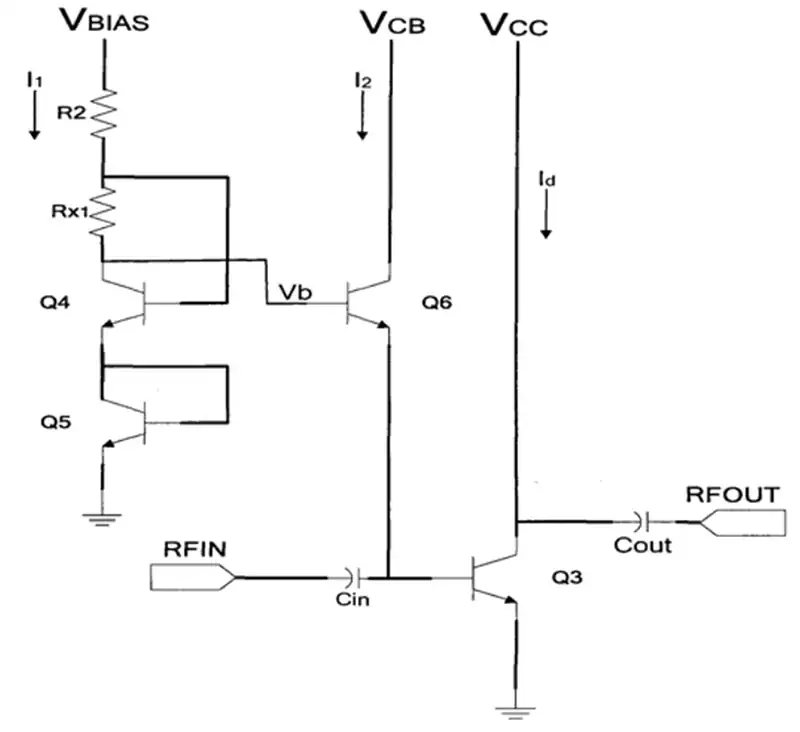

Multilayer ceramic pcb comprise ceramic green bodies, conductive pastes, and dielectric layers containing organic systems. These materials exhibit fundamental differences in elastic modulus, Poisson’s ratio, viscoelastic response, and thermal expansion behaviour.

During the lamination heating phase, the ceramic green body retains relatively high structural rigidity, while the organic bonding system gradually softens. Conductor paste areas exhibit greater local stiffness variations due to their higher metal filler content. This coexisting ‘soft-hard’ structural characteristic causes varying degrees of deformation across layers under identical applied loads.

When interlayer deformation fails to synchronise, pronounced shear stresses develop at interfaces. Should these stresses exceed interlayer friction or initial bonding strength, micro-slip occurs. As lamination pressure is continuously applied, this slip amplifies, ultimately manifesting as overall interlayer displacement or localised warping.

2.Insufficient Interlayer Friction and Bonding Establishment

During the initial lamination phase, particularly before temperatures reach the organic system’s activation range, layer-to-layer bonding relies primarily on mechanical friction rather than true adhesive forces. At this stage, the surface condition of the green substrate, the distribution of conductor patterns, and the organic content significantly influence the interlayer friction coefficient.

Should pressure application be uneven or significant localised differences in rigidity exist, insufficient interlayer friction to resist shear stress will result in relative slip. Furthermore, excessively rapid heating rates causing pronounced flow in the organic system before a stable adhesive network forms will weaken interlayer constraint, thereby increasing displacement risk.

3.Non-uniform pressure and temperature distribution

The structure and condition of the lamination equipment directly influence displacement and deformation. Inadequate parallelism of the press plates, localised differences in rigidity, or poorly designed buffer layers can all lead to uneven pressure distribution across the substrate surface. Areas subjected to higher pressure are more prone to compressive deformation, while regions with insufficient pressure may experience inadequate bonding, ultimately causing overall warping or edge misalignment.

Concurrently, uneven temperature distribution presents a significant factor. Pronounced thermal gradients cause varying degrees of softening in organic systems across different zones, resulting in inconsistent material flow. These disparities translate into internal stress concentrations during lamination, facilitating asymmetric slip and deformation between layers.

4.Inadequate Registration and Reference Design

Within multilayer ceramic pcb, the registration system not only facilitates assembly positioning but also directly influences displacement control during lamination. Relying solely on mechanical pins or simple registration holes without accounting for material flow, compression, and subsequent sintering shrinkage under pressure and heat often results in initial registration accuracy being compromised post-lamination.

Particularly in large-format or high-layer-count structures, cumulative material deformation magnifies minute initial errors, transforming initially acceptable alignment deviations into pronounced misalignment post-lamination. Furthermore, the absence of a unified reference layer or symmetrical structural design exacerbates deformation uncertainty, compromising the reproducibility of the lamination process.

Precision Control of Laminating Process Parameters

1.Staged Pressurisation and Temperature Increase Strategy

The phased process of pre-pressing—main pressing—pressure holding constitutes one of the core methods for mitigating the risk of interlayer displacement. During the pre-pressing stage, applying a low and stable pressure ensures thorough adhesion between layers and expels interlayer air, while avoiding excessive shear stress before the organic system softens. The primary objective here is not densification, but establishing a reliable initial contact state and geometric constraints.

As temperature gradually increases into the organic system’s activation range, the main pressing phase commences. With materials exhibiting sufficient fluidity, progressively elevated pressure facilitates the formation of continuous, uniform adhesive interfaces between layers. Excessively rapid pressure increases may induce lateral material flow in localised areas, leading to interlayer slippage; conversely, a gradual pressure rise strategy aids in stress release and redistribution.

During the pressure holding phase, maintaining stable temperature and pressure conditions for a defined duration allows the interlayer bonding structure to fully cure. This locks the laminated position, preventing rebound and secondary displacement during pressure release or cooling.

2.Pressure Uniformity and Equipment Rigidity Management

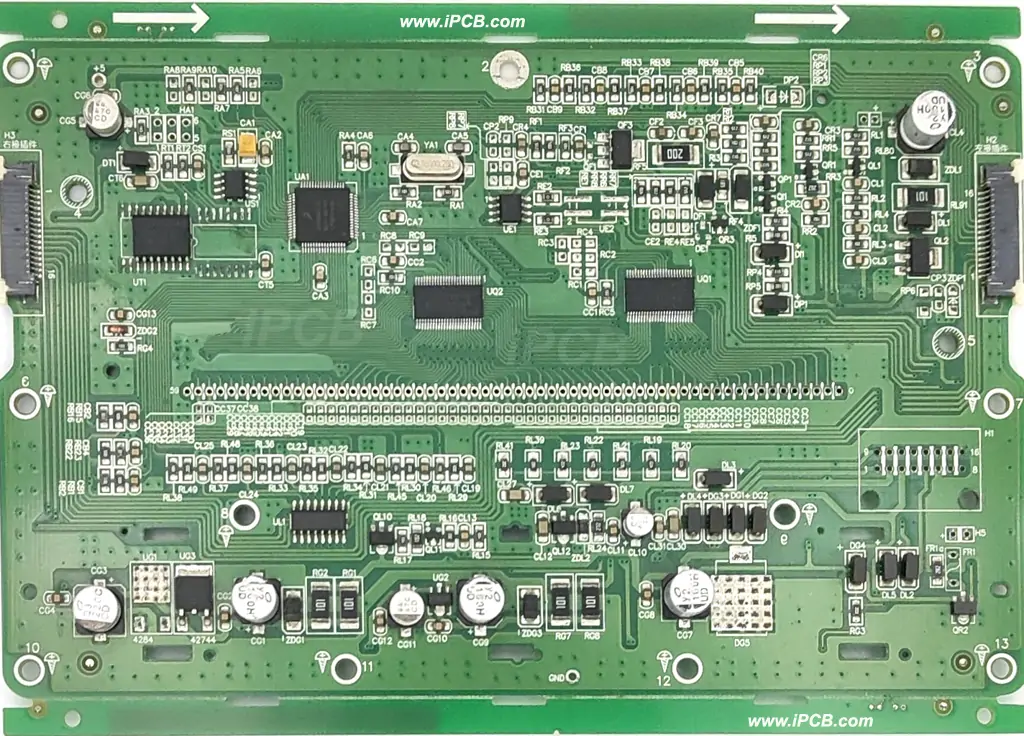

The uniformity of pressure distribution directly determines the stability of the stress field during lamination. Parallelism deviations between upper and lower platen surfaces, even under identical nominal pressure, generate pronounced pressure gradients across substrate surfaces, causing localised overpressurisation or underpressurisation. Such uneven loading is a primary contributor to edge misalignment and overall warpage.

Consequently, regular calibration of lamination equipment is essential to ensure platen parallelism and overall rigidity meet process specifications. For large-format or high-layer-count multilayer ceramic pcb, relying solely on the equipment’s inherent rigidity is often insufficient. Appropriate buffer layers or compliant layers must be incorporated. Such materials compensate for thickness variations at the microscopic level and absorb transient pressure fluctuations, resulting in more uniform stresses applied to the substrate. This reduces the probability of interlayer slippage and localised deformation.

3.Temperature Field Consistency Control

During lamination, temperature not only influences the softening and flow behaviour of organic systems but also directly determines the timing and manner of interlayer bonding establishment. Significant temperature gradients within the laminated area cause materials at different positions to exhibit distinct viscoelastic states, leading to inconsistent flow rates and compression levels.

Through multi-point temperature measurement and thermal field calibration, temperature dead zones or hot spots within the lamination equipment can be identified and corrected, promoting uniform overall temperature distribution. For multilayer ceramic pcb with complex structures or large dimensions, optimising the heating rate may also be necessary to prevent premature softening and asymmetric flow caused by excessive localised heating.

When the temperature field remains stable and uniform, each layer of material enters a similar viscoelastic state within the same time window. This facilitates synchronised deformation under pressure, fundamentally reducing the risk of displacement and warpage during the pressing process.

Cooperative Optimisation of Structure and Alignment Design

1.High-Precision Alignment Holes and Unified Reference System

The alignment system for multilayer ceramic pcb serves not only as an assembly tool but also as a critical structural element constraining displacement during lamination. By establishing a unified reference layer during the design phase and incorporating compensation design based on material shrinkage characteristics during lamination and sintering, the amplification effect of initial alignment errors during lamination can be effectively mitigated.

High-precision alignment holes, coupled with a stable reference system, help maintain the relative positioning of layers throughout the lamination cycle, providing a reliable foundation for subsequent sintering.

2.Process Borders and Sacrificial Zone Design

Incorporating process borders or sacrificial zones around functional circuit areas effectively mitigates stress concentration and displacement propagation during lamination. Such structures absorb partial stresses and material flow during lamination, directing deformation primarily to non-functional regions. This safeguards alignment precision and structural integrity within core circuit zones.

Process Monitoring and Quality Validation

1.Pre- and Post-Lamination Alignment and Warpage Inspection

Systematic dimensional, alignment, and warpage measurements before and after lamination provide tangible insights into displacement and deformation trends. Techniques such as optical metrology, X-ray inspection, and cross-sectional analysis furnish reliable data for process optimisation.

2.Implementation of Statistical Process Control (SPC)

Incorporating critical parameters such as pressure, temperature, and time into an SPC management system enables timely identification of abnormal fluctuations during mass production, preventing displacement issues from accumulating and amplifying over extended manufacturing runs. Data-driven continuous refinement of the process window facilitates long-term stability and repeatability in multilayer ceramic pcb lamination.

Displacement and deformation occurring during multilayer ceramic PCB lamination fundamentally result from the interaction between material properties, process conditions, and structural design. Optimising any single aspect alone cannot fundamentally resolve the issue. Only by addressing the material system at its source, combining phased lamination strategies with stable, controllable pressure and temperature fields, and fully accounting for process response in structural and alignment design, can a reliable constraint mechanism be established during lamination.

As multilayer ceramic PCB advance towards higher layer counts, greater precision, and larger dimensions, the stability of the lamination process will directly determine product consistency and yield rates. Transforming experience-based processes into replicable, predictable engineering capabilities through data-driven monitoring and continuous optimisation is the essential pathway to achieving high-quality mass production.