In the RF PCB design process, the selection of high-frequency laminates often falls into the dual pitfalls of prioritising performance at all costs and prioritising cost at all costs. A prevalent misconception within the industry holds that high-frequency applications necessitate premium high-frequency laminates, viewing high-end materials like Rogers as the sole guarantee of performance. This overlooks the principle of balancing actual project requirements with total lifecycle costs. FR4, as the most widely used PCB substrate in electronics manufacturing, is not inherently unsuitable for high-frequency applications. Similarly, the superior performance of Rogers high-frequency boards is not an absolute requirement for all RF pcb. Should RF PCBs necessitate the investment in Rogers high-frequency boards? The core answer lies in achieving precise alignment between performance requirements, application scenarios, and cost budgets.

Fundamental Differences Between FR4 and Rogers High-Frequency Materials

FR4 substrates are fundamentally composed of glass fibre-reinforced epoxy resin copper-clad laminates. These are formed by laminating copper foil between an epoxy resin binder phase and a glass fibre cloth reinforcement phase. Conventional FR4 exhibits a dielectric constant (Dk) range of 4.2–4.8 and dielectric loss (Df) of 0.015–0.02, resulting in relatively pronounced signal attenuation at high frequencies. However, performance enhancements are achievable through formulation optimisation: low-loss FR4 employs modified epoxy resin and high-performance glass fibre cloth, controlling Dk within 3.8–4.2 and reducing Df to 0.008–0.012, thereby significantly improving high-frequency compatibility. FR4’s core competitive advantages lie in its mature production processes, robust supply chain assurance, and cost-effectiveness, with its unit area cost being merely a fraction of that of high frequency boards. reducing Df to 0.008–0.012, significantly enhancing high-frequency compatibility. FR4’s core competitive advantages lie in its mature production processes, robust supply chain assurance, and cost-effectiveness, with unit area costs representing merely one-fifth to one-tenth of Rogers high frequency boards.

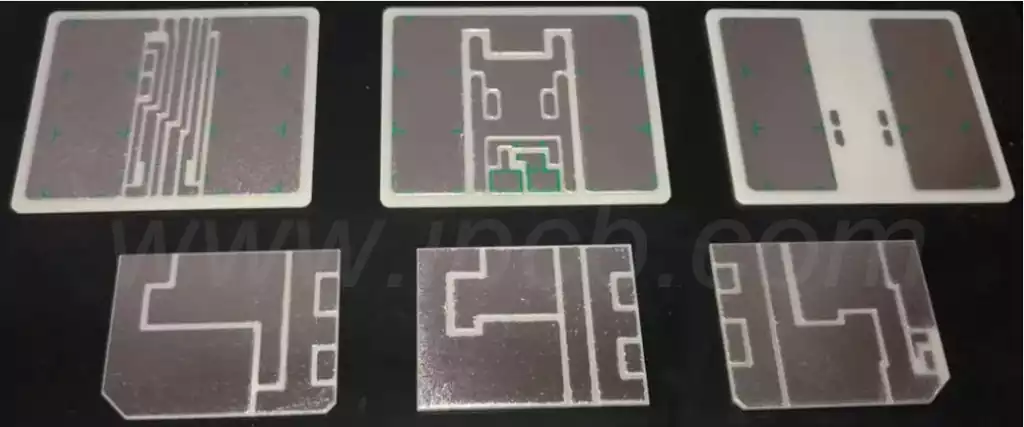

Rogers high frequency boards are positioned for extreme high-frequency performance, with core substrates including polytetrafluoroethylene (PTFE, e.g., Rogers 4350 series), ceramic-filled composites (e.g., Rogers 6006 series), and hydrocarbon/ceramic composites (e.g., Rogers 3003 series). The core technological advantage of these substrates lies in their exceptional and stable dielectric properties: Dk values as low as 2.2–3.5, with frequency and temperature variations ≤±0.02; Df values of merely 0.001–0.004, minimising transmission attenuation and energy loss for high-frequency signals. Furthermore, Rogers high-frequency boards exhibit a lower coefficient of thermal expansion (CTE) and superior dimensional stability, precisely meeting the high-precision assembly requirements of RF components. However, these technical advantages come with significant cost disadvantages: the substrate raw materials are expensive, and the production processes are highly complex (e.g., PTFE substrate lamination requires precise control of high temperature and pressure). The cost per unit area is 5-10 times that of conventional FR4, with some high-end models exhibiting even more pronounced cost differences.

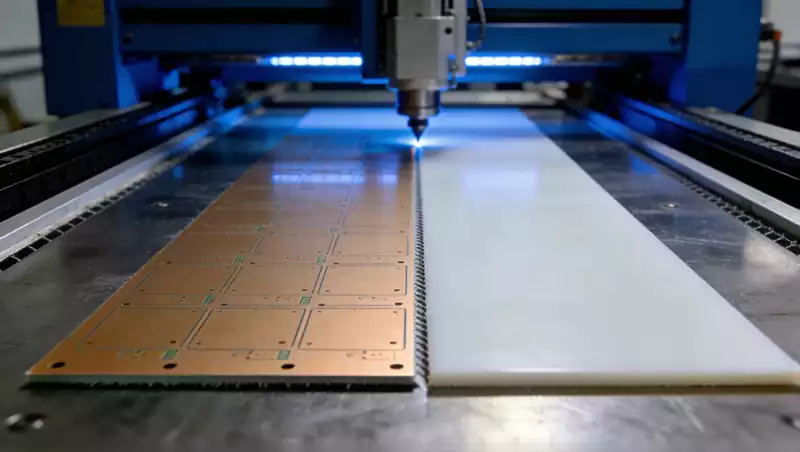

From a manufacturing perspective, FR4 processing has achieved standardisation. Key stages such as drilling, etching, and solder mask printing require no specialised equipment, facilitating large-scale production. In contrast, processing Rogers high frequency boards presents considerably higher barriers. The PTFE substrate’s inherent properties—high flexibility and low adhesion—make it prone to defects like delamination and voids during lamination. Drilling requires specialised tools and parameter control, while subsequent deburring and chemical cleaning processes demand unique techniques. Consequently, it is better suited to small-batch, high-precision custom production scenarios.

Performance Comparison:

1.Dielectric Properties

Dielectric properties constitute the core technical metric for RF laminates, directly influencing signal transmission attenuation, impedance matching precision, and crosstalk control efficacy. For RF projects, lower signal attenuation and more precise impedance matching form the fundamental basis for ensuring communication range, transmission rates, and operational stability.

Rogers high-frequency laminates demonstrate absolute superiority in dielectric properties: a low Dk value enhances signal transmission rates (transmission rate is proportional to √(1/Dk)), while a low Df value significantly reduces signal attenuation. At 24GHz, signal attenuation in Rogers 4350 laminate is merely one-third to one-half that of conventional FR4; At 60GHz millimetre wave frequencies, the attenuation difference exceeds 50%. Crucially, Rogers high-frequency boards exhibit minimal Dk variation with frequency and temperature fluctuations, ensuring stable impedance matching in complex operating environments and preventing signal reflection and distortion. This characteristic is vital for high-precision RF pcb such as 5G millimetre wave communications and satellite communications.

Although FR4’s dielectric properties fall short of Rogers high frequency boards, formulation optimisation can meet application requirements in mid-to-high frequency scenarios. Low-loss FR4 achieves a Df value below 0.008, keeping signal attenuation within manageable limits in the 2.4-5GHz band (e.g., WiFi 6, Bluetooth communication systems). Below 10GHz, where projects do not demand extreme communication range or transmission rates (e.g., industrial IoT, RFID applications), low-loss FR4 fully meets design specifications. However, above 18GHz, signal attenuation increases significantly and Dk values exhibit heightened fluctuation, rendering FR4 unsuitable for high-precision RF projects.

2.Thermal Stability

The manufacturing processes of RF projects (such as lead-free reflow soldering) and the end-use environments (e.g., high-temperature conditions in base stations or industrial control equipment) impose explicit demands on substrate thermal stability. Insufficient thermal stability leads to substrate defects like warping and delamination, thereby compromising the stability of RF performance.

Rogers high-frequency laminates exhibit outstanding thermal stability, with standard products typically featuring glass transition temperatures (Tg) exceeding 280°C. Certain grades (e.g., Rogers 6010) achieve 300°C, enabling stable operation in lead-free soldering environments (250–270°C) and sustained high-temperature conditions (120–150°C) within premium RF equipment. Concurrently, its coefficient of thermal expansion (CTE) exhibits high compatibility with copper foil, minimising post-soldering defects such as warping or deformation. This ensures precise assembly requirements for RF components.

FR4 thermal stability varies significantly by product grade: standard FR4 possesses a Tg of approximately 130-140°C, suitable only for conventional soldering processes and low-temperature applications; High-Tg low-loss FR4 elevates the Tg to 170–180°C, accommodating lead-free soldering processes and medium-to-high temperature operating environments (80–120°C), covering most consumer electronics and industrial control RF applications. However, in extreme temperatures exceeding 150°C, FR4’s mechanical strength and dielectric properties deteriorate significantly, rendering it unsuitable to replace Rogers high-frequency boards in such technical applications.

3.Dimensional Stability

The assembly precision of RF components (such as filters, antennas, power amplifiers, etc.) demands exceptional accuracy. The dimensional stability of the substrate directly impacts component alignment precision and RF performance—excessive dimensional deformation beyond permissible limits will cause impedance mismatch, exacerbate signal crosstalk, and even lead to assembly interference issues.

Rogers high-frequency laminates demonstrate exceptional dimensional stability. Their substrate exhibits a low and uniformly distributed CTE value, with a linear expansion rate of merely 10–15 ppm/°C across the -55°C to 150°C temperature range. This provides excellent compatibility with copper foil (17 ppm/°C), virtually eliminating warping or deformation defects during soldering and operation. This characteristic is crucial for high-precision RF components such as satellite communication antennas and millimetre-wave radars, serving as a core prerequisite for ensuring project performance metrics.

The dimensional stability of FR4 exhibits a gradient improvement through substrate optimisation: conventional FR4 has a CTE value of approximately 16-20 ppm/℃, prone to slight warping in high-temperature environments; High-Tg, low-loss FR4 employs specialised fillers to formulate a CTE value of 13-16 ppm/℃, significantly enhancing dimensional stability to meet assembly requirements for medium-precision RF applications like WiFi routers and industrial IoT gateways. However, under extreme temperature fluctuations or high-precision assembly scenarios, FR4’s dimensional stability remains inferior to Rogers high-frequency laminates.

4.Cost and Mass Production Viability

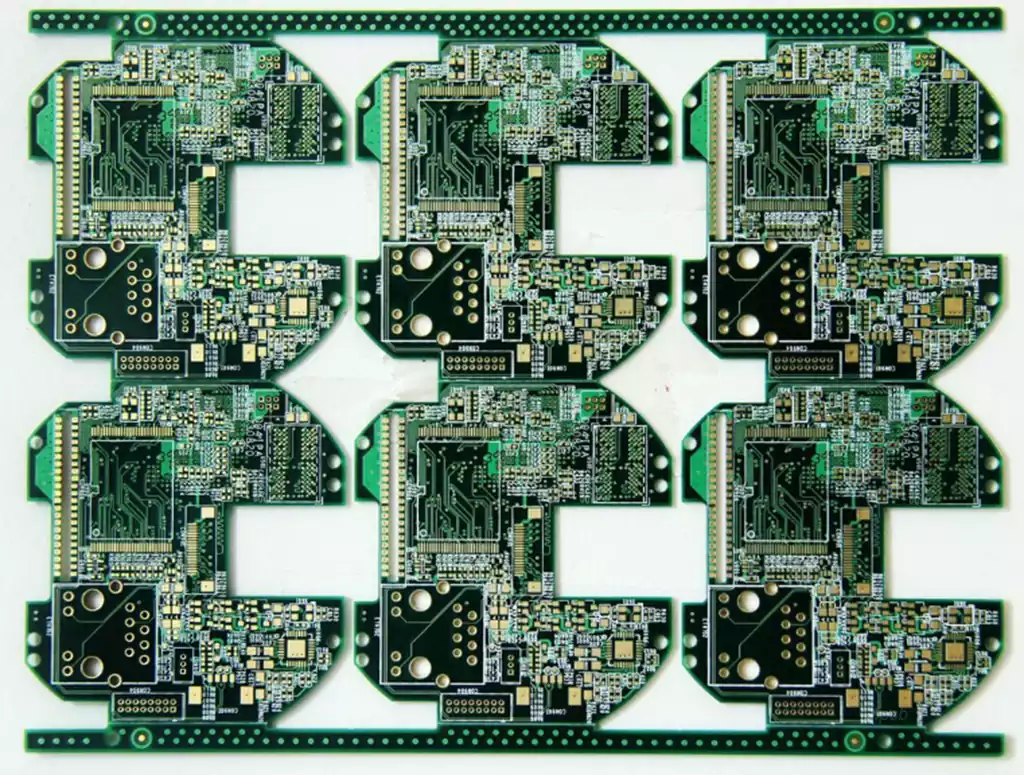

For high-volume RF projects in consumer electronics and industrial IoT terminals, cost control and mass production feasibility are pivotal factors in substrate selection. In such scenarios, FR4 offers irreplaceable advantages.

The unit area cost of FR4 is merely one-fifth to one-tenth that of Rogers high frequency boards. Its production processes are highly standardised, with robust supply chain assurance enabling daily output per machine to reach tens of thousands of sheets, efficiently supporting large-scale mass production demands. Taking WiFi 6 router RF boards as an example, the cost per board using low-loss FR4 is merely 2-5 yuan, whereas the cost for boards using Rogers 4350 material soars to 20-50 yuan. The cost disparity in mass production scenarios is exceptionally pronounced.

The high cost and complex manufacturing processes associated with Rogers high frequency boards make them ill-suited for large-scale, high-volume production. Its substrate materials are expensive, and the manufacturing process requires specialised equipment and customised fixtures, yielding only a few hundred boards per machine per day. It is better suited for small-batch, high-precision RF projects such as satellite communication equipment and high-end millimetre-wave radar. Such projects are typically less cost-sensitive and demand extreme performance metrics, where the technical advantages of Rogers high-frequency boards effectively offset their cost disadvantages.

Principles for Matching Materials in RF PCBs

1.Consumer Electronics RF Projects (WiFi 6/6E, Bluetooth, RFID)

Application Characteristics: Operating frequency bands range from 2.4 to 7.125 GHz. These projects exhibit extreme cost sensitivity, involve mass production at the million-unit scale, and require moderate performance metrics (communication range 10–100 metres, transmission rate ≤10 Gbps).

Selection Recommendations: Prioritise low-loss FR4. These projects exhibit high tolerance for signal attenuation, where low-loss FR4 fully meets design specifications while maximising cost control. Examples include WiFi 6 router RF boards and Bluetooth speaker antenna boards, where low-loss FR4 achieves optimal performance-cost balance without requiring Rogers high frequency boards.

2.Industrial Control RF PCBs (Industrial IoT, Smart Manufacturing RF Sensors)

Application Characteristics: Operating frequency range 1-6GHz; complex operating environments (requiring resistance to high temperatures, vibration, etc.); mass production scale ranging from ten thousand to one hundred thousand units; high reliability requirements; moderate cost sensitivity.

Selection Recommendations: Employ high-Tg low-loss FR4. The high Tg characteristic (170-180°C) accommodates industrial environments’ high-temperature demands, while low loss ensures stable signal transmission. Compared to Rogers high frequency boards, high-Tg low-loss FR4 offers significant cost advantages, meeting mid-volume production cost control requirements. Examples include industrial IoT gateway RF boards and smart manufacturing production line RF positioning sensors, all suitable for high-Tg low-loss FR4.

3.Mid-range Communication RF PCBs (5G Sub-6GHz Base Stations, Microwave Communication Equipment)

Application Characteristics: Operating frequency band of 3.5-6GHz with stringent signal integrity requirements (data rates ≥10Gbps, communication distance ≥1km). Mass production scale reaches ten thousand units, with moderate cost sensitivity.

Selection Recommendation: Adopt a hybrid solution combining ‘Rogers material in core areas + FR4 in non-core areas’. Projects of this type demand exceptional performance from core RF components. Employing Rogers high frequency boards in critical areas such as power amplifiers and filters ensures signal transmission quality, while utilising low-loss FR4 in non-critical zones achieves a balance between performance and cost. For instance, in the RF front-end of 5G Sub-6GHz base stations, the power amplifier module uses Rogers 4350 material, with other auxiliary circuits employing low-loss FR4.

4.High-end RF PCBs (5G millimetre wave, satellite communications, high-end millimetre wave radar)

Application characteristics: Operating frequencies range from 24-60GHz, demanding extreme signal integrity (signal attenuation ≤0.5dB/m, impedance matching accuracy ±5%). Harsh operating environments require tolerance to extreme temperatures, vacuum conditions, etc. Production volumes range from hundreds to thousands, with low cost sensitivity.

Selection Recommendations: Rogers high frequency boards are mandatory. Given the exceptionally high operating frequencies, FR4’s signal attenuation and Dk value fluctuations cannot meet design requirements. Rogers high frequency boards‘ low loss and high stability represent the sole technical solution to guarantee project performance. Examples include satellite communication equipment RF antenna boards and 60GHz millimetre-wave radar core RF boards, which require high-frequency boards such as Rogers 4350 or Rogers 6006.

5.Low-power, short-range RF PCBs (RF remote controls, short-range data transmission modules)

Application characteristics: Operating frequency range 100MHz–2.4GHz, low power (≤1W), short communication distance (≤10 metres), mass production volume reaching millions, with extreme cost sensitivity.

Selection recommendation: Standard FR4 is sufficient. These projects impose minimal RF performance requirements, with conventional FR4’s technical characteristics fully meeting design needs while enabling optimal cost efficiency. For instance, television RF remote controls and smart home short-range transmission modules achieve the best cost-benefit ratio using standard FR4.

Three-Step Method for Selecting RF PCB Materials

Define core requirements. Systematically organise key technical parameters for the project, including operating frequency bands (≤10GHz/10-24GHz/>24GHz), signal transmission distance and rate, operating temperature range, mass production scale, and cost budget range. This forms the foundational premise for material selection decisions, effectively preventing cost wastage arising from blind pursuit of high performance.

Assess performance priorities. If the project’s core requirement is ‘signal integrity prioritised over cost control’ (e.g., high-end millimetre-wave projects), Rogers high frequency boards should be prioritised. If the core requirement is ‘cost control prioritised over performance redundancy’ (e.g., consumer electronics projects), FR4 series boards should be prioritised. If a ‘balance between performance and cost’ is required (e.g., mid-range communications projects), a hybrid selection approach of ‘localised Rogers + overall FR4’ may be adopted.

Verify feasibility. Quantitatively compare the performance of both materials using RF simulation tools (e.g., HFSS, CST) to determine whether FR4 meets project design specifications. If simulation results approach critical thresholds, produce samples for physical verification (e.g., signal attenuation measurements, impedance matching precision tests) to prevent selection errors. For instance, in a 10GHz RF project, simulation revealed that low-loss FR4 exhibited only 1dB higher signal attenuation than Rogers high frequency board, falling within the project’s permissible tolerance range. This confirmed the suitability of low-loss FR4.

The selection between FR4 and Rogers high frequency boards is not a simple performance contest, but a process of precise alignment with project requirements. Rogers high frequency boards provide ultimate performance, serving as the core technological assurance for high-end RF projects. FR4’s high cost-effectiveness and mass production advantages make it the core choice for cost optimisation in mainstream RF projects. Within the industry, there exists neither an absolute conclusion that ‘all RF projects must use Rogers high-frequency boards’ nor should there be a rigid perception that ‘FR4 cannot be used in high-frequency scenarios’.