Arlon Electronic Materials, a division of Rogers Corporation, is a globally recognized manufacturer specializing in high-performance laminate and prepreg materials for printed circuit boards (PCBs). These materials are critical in various high-technology sectors, including aerospace, defense, telecommunications, and industrial electronics. With a commitment to innovation and quality, Arlon has established itself as a leader in the field, providing solutions that meet the stringent demands of modern electronic applications.

Historical Background and Evolution

Founded in 1954, Arlon began its journey focusing on the development of silicone rubber materials. Over the years, the company expanded its product line to include high-performance laminates and prepregs, addressing the evolving needs of the electronics industry. Continuous investment in research and development has allowed Arlon to build a broad portfolio of products tailored to various high-performance applications.

In 2015, Arlon was acquired by Rogers Corporation, a global leader in engineered materials. This strategic acquisition enabled Arlon to leverage Rogers’ extensive resources and expertise, further enhancing its capabilities and expanding its market reach.

Comprehensive Product Portfolio

Arlon’s product portfolio is diverse, catering to a wide range of applications. Key products include:

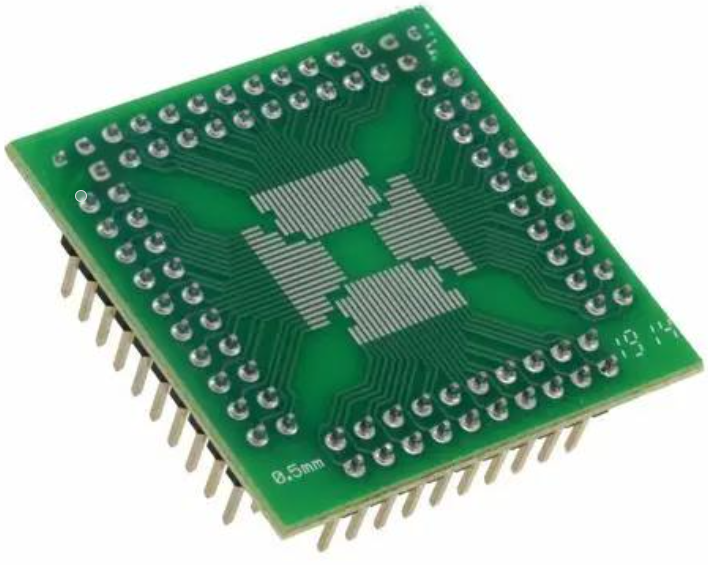

- High-Frequency Laminates: Designed for applications requiring exceptional electrical performance, such as RF and microwave circuits. These laminates offer low dielectric constant and low loss, making them ideal for high-speed digital and high-frequency analog circuits.

- High-Temperature Laminates: These materials can withstand extreme thermal environments without compromising performance, making them suitable for aerospace and defense applications.

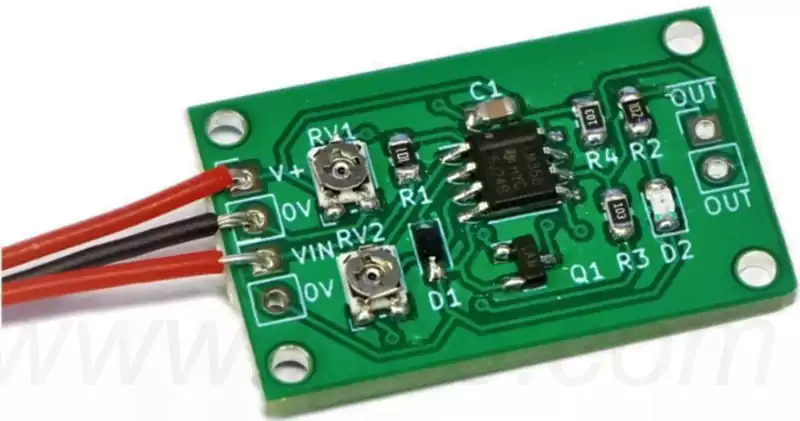

- Thermally Conductive Laminates: Engineered to provide efficient heat dissipation in electronic assemblies, crucial for maintaining reliability and performance in high-power applications.

- Flex-Rigid Laminates: Combining the benefits of flexible and rigid materials, these laminates are used in complex circuit designs that require both flexibility and structural integrity.

Industry Applications

Arlon’s electronic materials are utilized across various industries, each with specific requirements:

- Aerospace and Defense: The demanding nature of aerospace and defense applications necessitates materials that can endure harsh environmental conditions while delivering reliable performance. Arlon’s high-temperature and high-frequency laminates are commonly used in avionics, radar systems, and satellite communications.

- Telecommunications: The rapid expansion of telecommunications infrastructure, including 5G networks, requires materials that support high-speed data transmission and low signal loss. Arlon’s high-frequency laminates are ideal for base stations, antennas, and other communication devices.

- Industrial Electronics: In industrial environments, electronic materials must endure rigorous conditions such as high temperatures, chemical exposure, and mechanical stress. Arlon’s products are used in power supplies, motor controls, and industrial automation systems.

- Automotive Electronics: The increasing integration of electronic systems in vehicles, from infotainment to advanced driver-assistance systems (ADAS), drives the demand for reliable and high-performance materials. Arlon’s thermally conductive and high-frequency laminates are utilized in various automotive applications.

Commitment to Innovation and Research

Arlon’s success is fueled by its dedication to innovation and continuous improvement. The company’s research and development efforts focus on advancing material science and developing new solutions to meet emerging industry needs. Arlon collaborates with customers, industry partners, and academic institutions to stay at the forefront of technological advancements.

A significant area of innovation is the development of materials for 5G applications. As the industry transitions to 5G, there is a need for materials that can support higher frequencies and faster data rates. Arlon is actively developing high-frequency laminates that meet these requirements, enabling the deployment of next-generation communication networks.

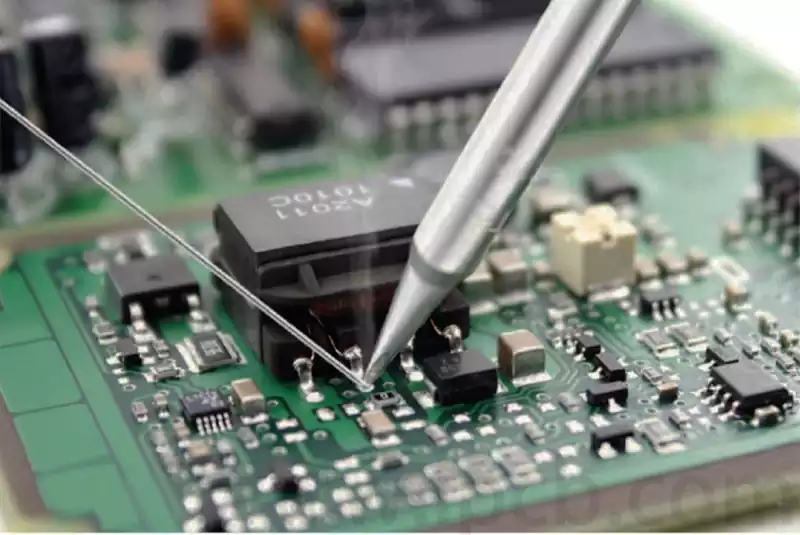

Ensuring Quality and Reliability

Quality is a cornerstone of Arlon’s business philosophy. The company adheres to stringent quality control processes to ensure that its products meet the highest standards of performance and reliability. Arlon’s manufacturing facilities are ISO 9001 certified, reflecting the company’s commitment to excellence in every aspect of its operations.

Arlon’s dedication to quality extends beyond manufacturing. The company provides comprehensive technical support to assist customers in selecting the right materials for their applications and optimizing their PCB designs. This collaborative approach helps ensure that customers achieve the best possible performance and reliability from Arlon’s products.

Sustainability and Environmental Responsibility

As a responsible corporate citizen, Arlon is committed to sustainability and minimizing its environmental impact. The company implements environmentally friendly practices throughout its operations, from raw material sourcing to manufacturing and product disposal. Arlon’s products are designed to meet regulatory requirements and industry standards for environmental safety.

In addition to its internal sustainability efforts, Arlon collaborates with customers and partners to develop solutions that contribute to a more sustainable electronics industry. This includes the development of materials with reduced environmental impact and improved energy efficiency.

Global Presence and Market Reach

Arlon’s global presence is supported by a network of manufacturing facilities, sales offices, and distribution partners. This enables the company to serve customers in key markets around the world and provide localized support. Arlon’s products are trusted by leading electronics manufacturers and are used in critical applications across the globe.

Future Outlook

Looking ahead, Arlon is poised to continue its leadership in the electronic materials industry. The company is actively exploring new technologies and materials to address the challenges of emerging applications. With a strong focus on innovation, quality, and sustainability, Arlon is well-positioned to meet the evolving needs of the electronics industry.

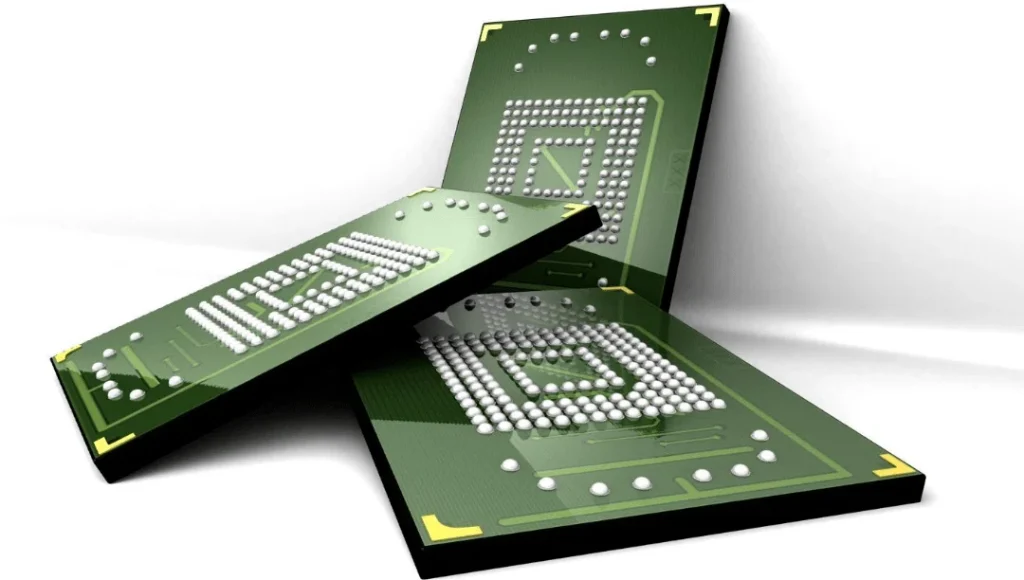

One of the key areas of focus is the development of materials for advanced semiconductor packaging. As electronic devices become more compact and powerful, there is a growing demand for materials that can support high-density interconnects and advanced packaging technologies. Arlon is investing in research to develop laminates and prepregs that meet these requirements, ensuring that its customers can stay ahead in the rapidly changing electronics landscape.

Another area of potential growth is the increasing adoption of electric vehicles (EVs). The rise of EVs is driving the need for advanced electronic materials that can handle higher power levels and thermal management challenges. Arlon’s thermally conductive laminates are well-suited for these applications, providing efficient heat dissipation and enhancing the reliability of electronic components in EVs.

Arlon is also exploring opportunities in renewable energy sectors, such as wind and solar power. The electronics used in these applications require materials that can withstand harsh outdoor environments and deliver long-term reliability. Arlon’s high-performance laminates are ideal for use in power converters, inverters, and other critical components of renewable energy systems.

Conclusion

Arlon Electronic Materials has built a reputation for excellence in the electronic materials industry. With a rich history of innovation, a diverse product portfolio, and a commitment to quality and sustainability, Arlon continues to lead the way in providing high-performance solutions for the most demanding electronic applications. As the electronics industry evolves, Arlon remains at the forefront, delivering materials that enable the next generation of technological advancements.

Arlon’s journey from its founding in 1954 to its current status as a division of Rogers Corporation is a testament to its commitment to excellence and innovation. By continually adapting to the changing needs of the electronics industry and investing in cutting-edge research and development, Arlon has positioned itself as a trusted partner for companies seeking high-quality electronic materials. With a focus on sustainability and environmental responsibility, Arlon is not only meeting the needs of today but also paving the way for a greener and more efficient future in electronics.

Arlon’s commitment to customer satisfaction is evident in its comprehensive technical support and collaborative approach. By working closely with customers to understand their unique requirements and challenges, Arlon ensures that its products deliver optimal performance and reliability. This customer-centric approach has helped Arlon build long-term relationships with leading electronics manufacturers around the world.

In summary, Arlon Electronic Materials stands out as a leader in the electronic materials industry, driven by a relentless pursuit of innovation, quality, and sustainability. With a strong foundation and a forward-looking vision, Arlon is well-equipped to meet the demands of the future, supporting the advancement of technology across various high-performance applications.