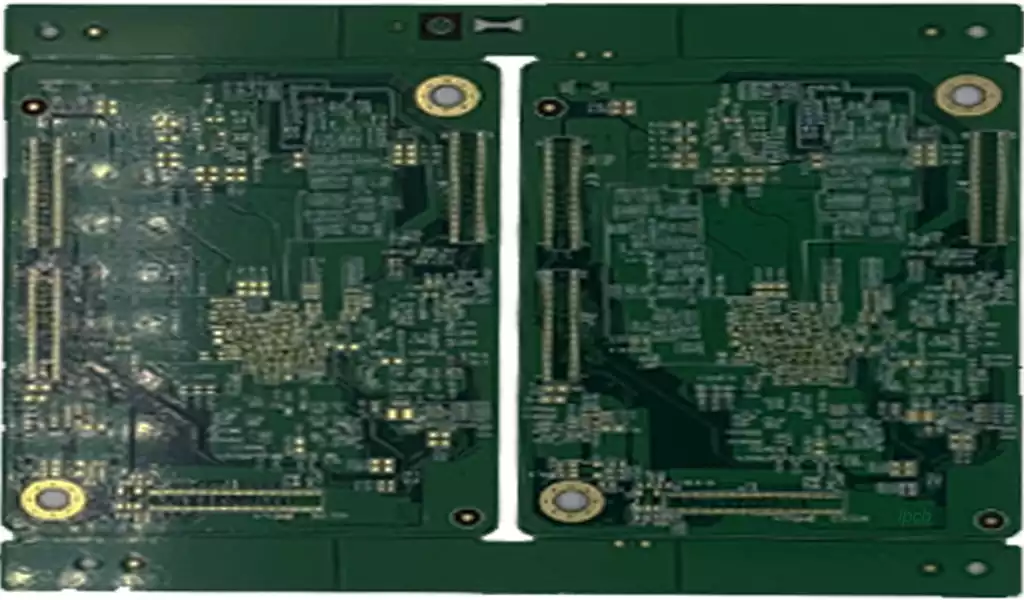

Arlon pcb is a printed circuit board made from special materials manufactured by Arlon Corporation. Arlon substrate has stable electrical properties and mechanical strength that maintain performance under a variety of environmental conditions. Its low dielectric constant and low loss factor reduce losses and delays during signal transmission, meeting the needs of high-speed signal transmission and high-frequency communication applications. In addition, strong mechanical strength and impact resistance maintain structural integrity in harsh operating environments.

Material Characteristics

High stability: the use of high-quality base materials and special processes to ensure the stability of the performance of the printed circuit board in a variety of environmental conditions. Whether in high temperature, low temperature, humid or dry environment, can maintain stable electrical properties and mechanical strength, for the reliable operation of electronic equipment to provide protection.

Efficient Transmission: With a low dielectric constant and low loss factor, it reduces losses and delays during signal transmission. This makes Arlon PCBs ideal for high-speed signal transmission and high-frequency communication applications, meeting the high performance needs of modern electronics.

High Mechanical Strength: Precision machined and reinforced to provide high mechanical strength and impact resistance. This allows Arlon PCBs to maintain structural integrity and provide reliable circuit connections in a variety of harsh operating environments.

Environmentally Sustainable: Compliant with environmental requirements, Arlon PCBs utilize environmentally friendly materials and production processes that are not harmful to the environment. At the same time, Arlon is committed to recycling resources and reducing waste generation to promote the goal of sustainable development.

Categorization:.

Classification by material: According to the different substrates, Arlon printed circuit boards can be classified into FR4, CEM-1, aluminum substrate, copper substrate, ceramic substrate, and so on. These different substrates have different electrical and physical properties and are adapted to different application scenarios.

Classification by thickness: According to the thickness of the circuit board, it can be divided into thick board, thin board, regular board, etc.. Thick boards are usually used in applications that require greater mechanical stress, thin boards are used in applications with higher weight and size requirements, and regular boards are used in the manufacture of general electronic products.

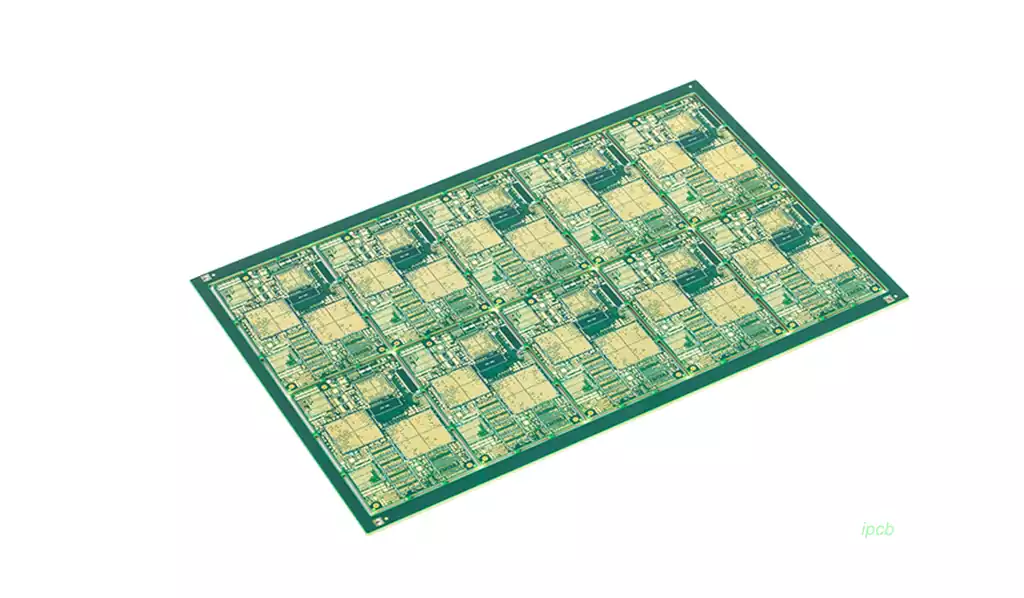

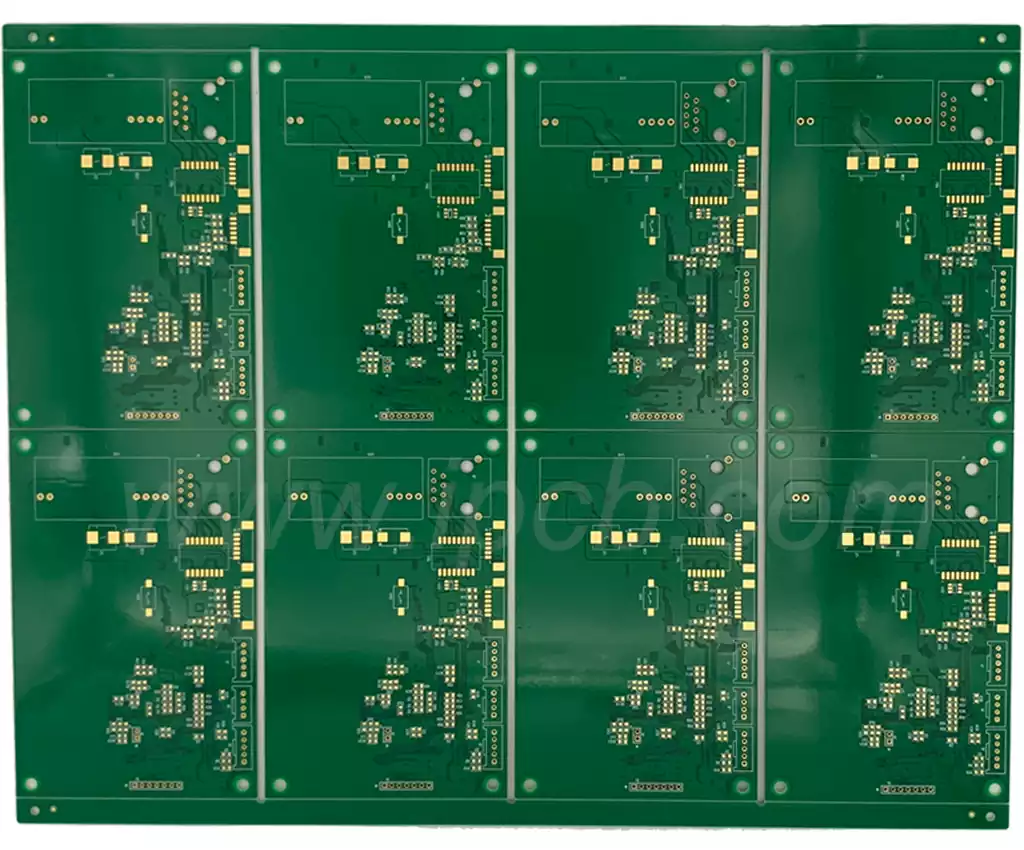

Classification by number of layers: According to the number of layers of the circuit board, it can be divided into single-sided boards, double-sided boards, multilayer boards, and so on.Single-sided boards have a conductive layer on one side only, double-sided boards have a conductive layer on both sides, and multilayer boards are composed of multiple conductive layers, which have higher electrical performance and stability.

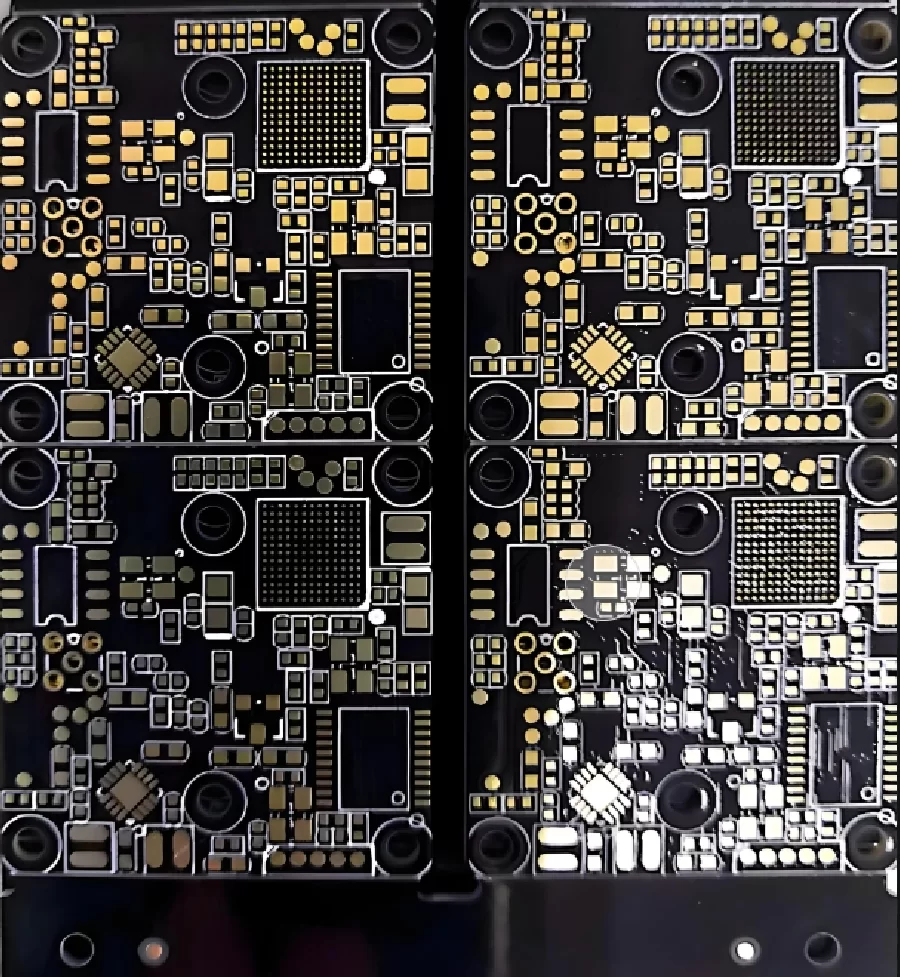

Classification by surface treatment: The surface treatment of the circuit board can be divided into gold-plated, tin spray, immersion gold, OSP, and so on. Different surface treatment has different effects on the electrical performance and reliability of the circuit board and should be selected according to specific needs.

Classification by special process: According to the requirements of the special process, it can be divided into impedance boards, buried blind hole boards, HDI boards, and so on. These special processes can meet the specific application requirements, improve the performance and reliability of the board

Arlon PCB and copper-clad boards differ in several ways:

Material and Construction:

Copper-clad laminates are copper-clad sheets with copper foil on one side and a chemical varnish on the other and are primarily used for electrochemical processing and electrode chemical processing.

Arlon substrates, on the other hand, are circuit boards made of conductive copper foil over an insulating board and are commonly used in the manufacture of electronic products.

Manufacturing Methods:

The manufacturing method for copper-clad boards involves copper foil covered in a resin layer on both sides, which is fixed by a chemical reaction.

Manufacturing of Arlon printed circuit boards involves printing circuit diagrams onto the copper-clad board and chemically etching away the unwanted copper layer, leaving behind a patterned chemical adhesive and copper layer.

Areas of Application:

Copper-clad laminates are mainly used for electrochemical processing and electrode chemical processing.

Arlon printed circuit boards, on the other hand, are mainly used in the manufacture of electronic products such as household appliances, computers and cell phones.

Application Scenario:

Copper-clad laminates are mainly used for electrochemical and electrode chemical processes, which involve complex chemical reactions.

Arlon substrate, on the other hand, is used in electronic circuits and circuit systems and are the core component of electronic circuit systems.

Environmental friendliness:

Arlon substrate is environmentally friendly and committed to recycling resources and reducing waste.

Arlon PCB is widely used in the following areas:

Communications: With stable electrical properties and low dielectric constants, they are suitable for manufacturing key components in communications equipment, such as routers, switches, and base stations.

Aerospace: Ideal for flight control systems and satellite communication systems due to its high reliability and heat resistance.

Medical electronics field: widely used in medical equipment, such as pacemakers, monitors, etc., which provides a reliable guarantee for the normal operation of medical equipment.

Automotive electronics: Arlon printed circuit boards provide efficient and stable circuit connections for automotive electronic systems, especially in security and entertainment systems.

Industrial control: Arlon substrate is used in industrial control systems to stabilize the operation of various electronic devices.

Smartphones and other consumer electronics: Arlon substrate is also widely used in smartphones and other consumer electronics to provide efficient and stable circuit connections.

IPCB is a professional Arlon PCB manufacturer. If you need, please contact IPCB