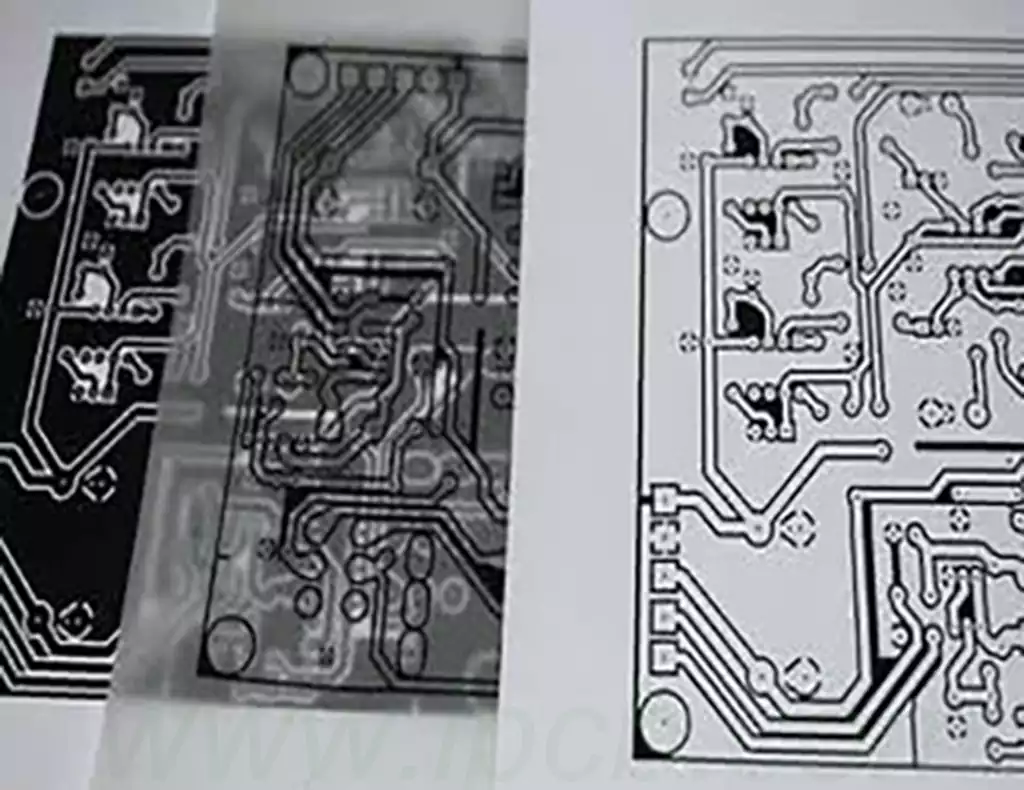

Negative and positive film in PCB

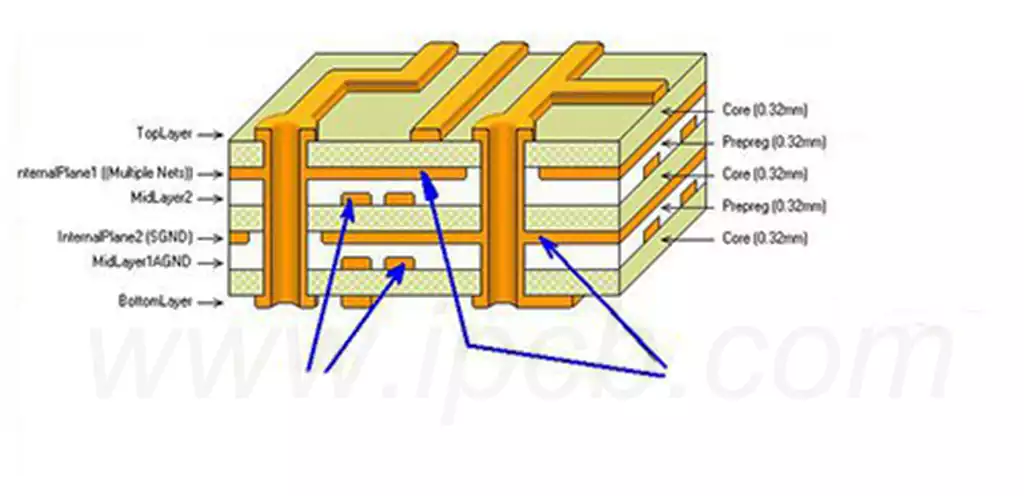

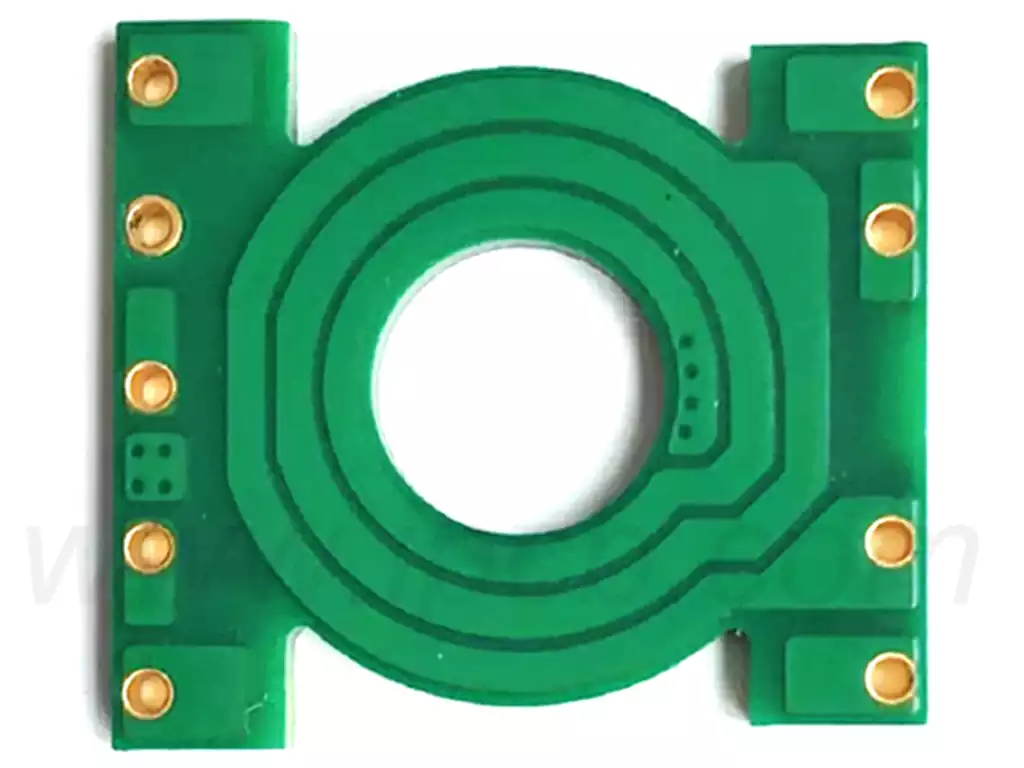

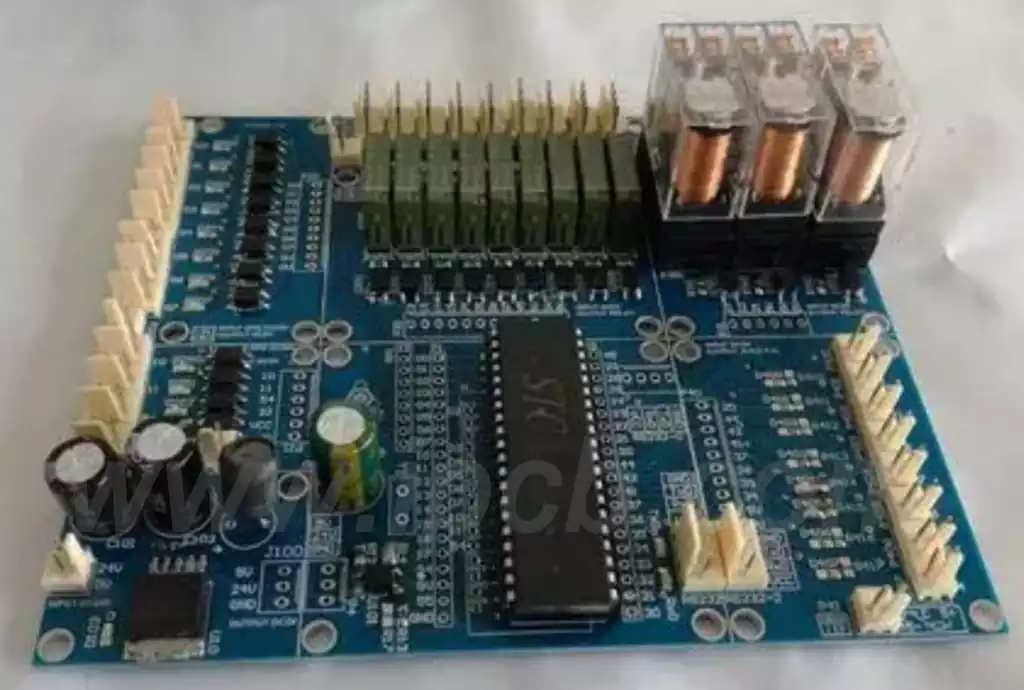

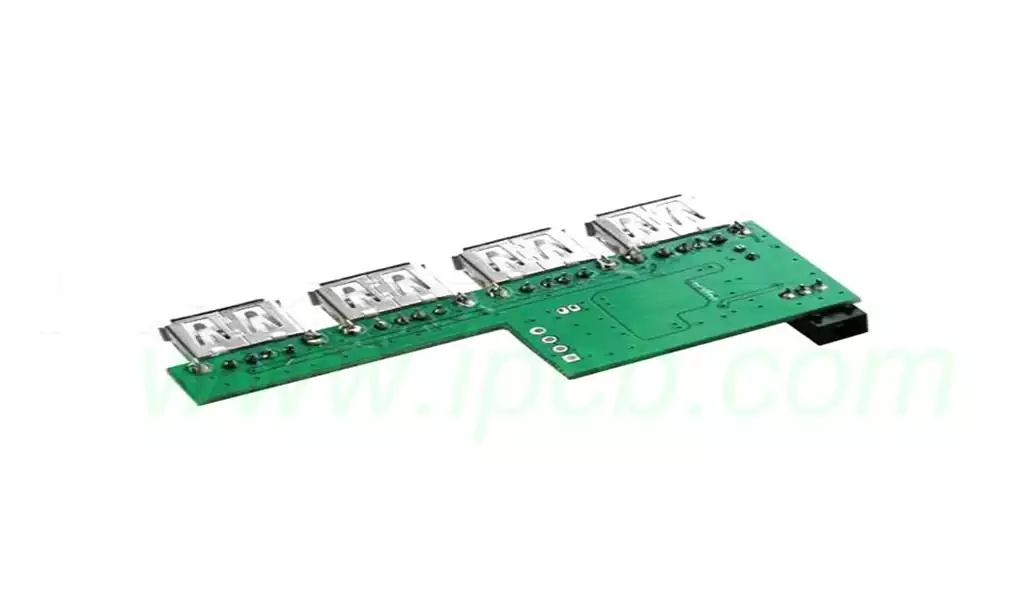

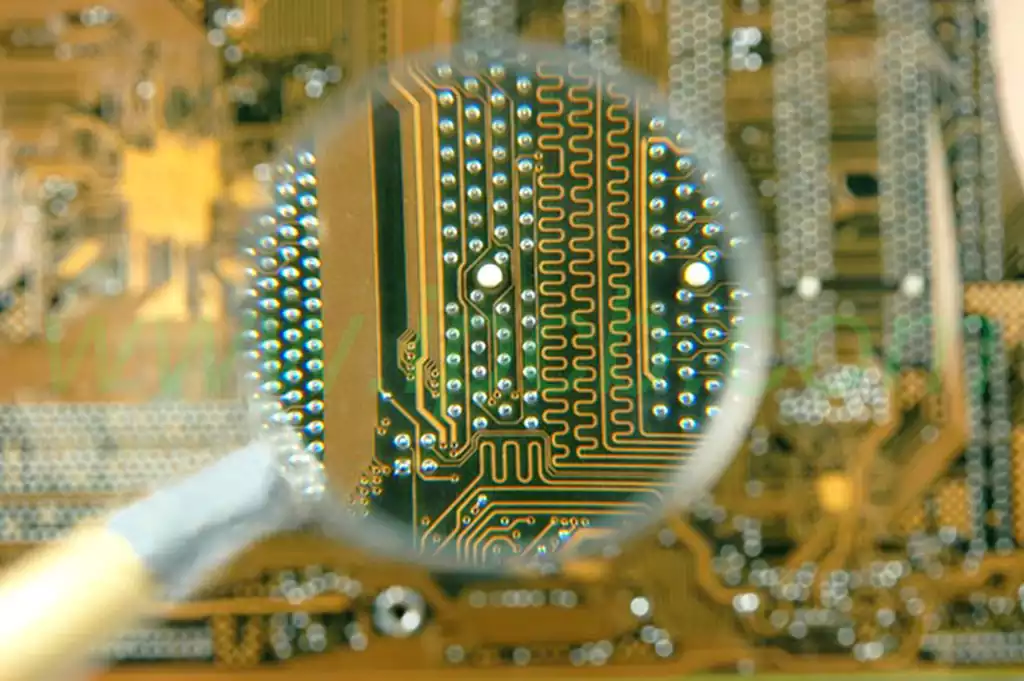

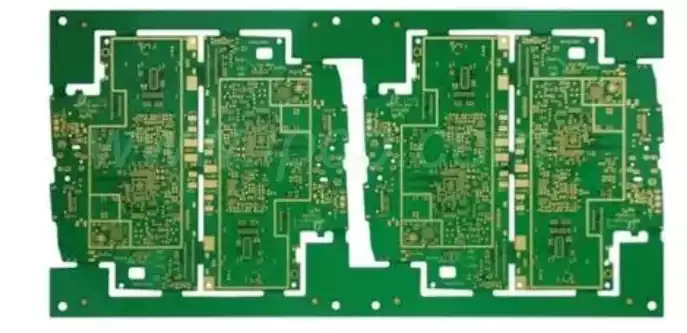

Negative and positive film are two forms of image processes used in the production of printed circuit boards (PCBs). Positive lamination refers to the manufacturing of circuit boards in which drawn lines and patterns are retained and unpainted areas are removed. This process often utilizes alkaline etching, and the end result is that the necessary […]