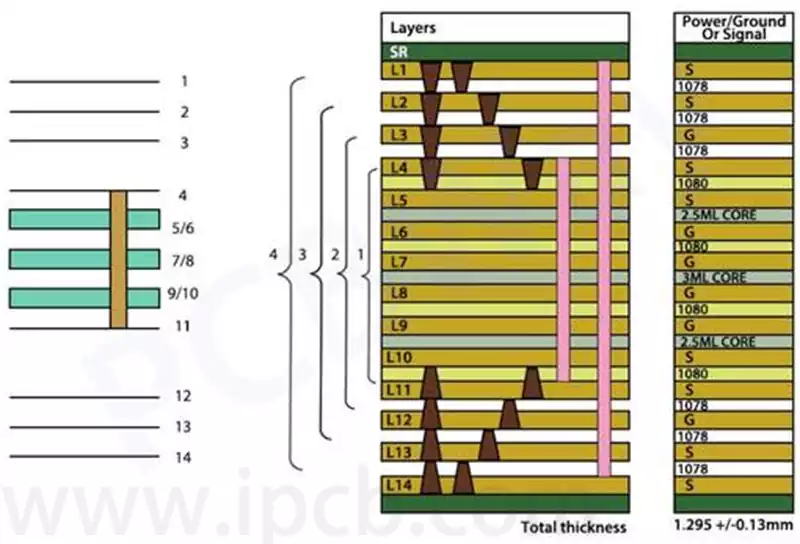

Process Principles and Development of Hybrid Bonding Technology

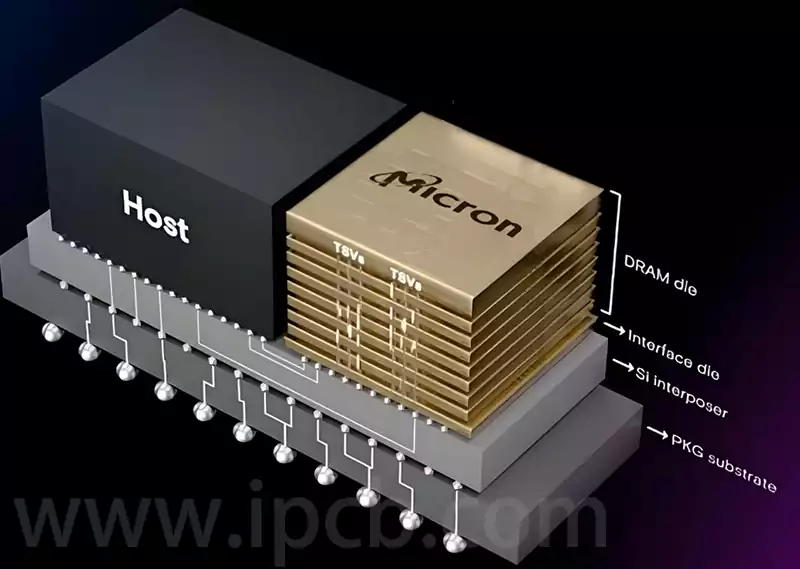

Hybrid Bonding is an advanced IC packaging technology used to achieve high-density, high-performance interconnections between different chips. The key feature of this technology is to replace the traditional bump or solder ball (bump) interconnections with direct copper-to-copper connections, which enables ultra-fine pitch stacking and packaging in a very small space for the purpose of three-dimensional […]