BGA packages is solder ball array package, is an integrated circuit using an organic carrier board packaging method. With the continuous development of society, in order to meet the demand for electronic products light, thin, short, small and functional diversification, production of green and other aspects of the BGA package began to be applied to the production of a number of advanced high-density packaging technology has been born, BGA packaging technology is one of them. Although the performance and assembly of BGA devices is superior to conventional components, but because the testing of BGA device solder joints is quite difficult, it is difficult to ensure its quality and reliability, so many manufacturers are reluctant to invest in the development of high-volume production of BGA device capabilities.

BGA packages have the following features and advantages over other package forms:

I/O Density

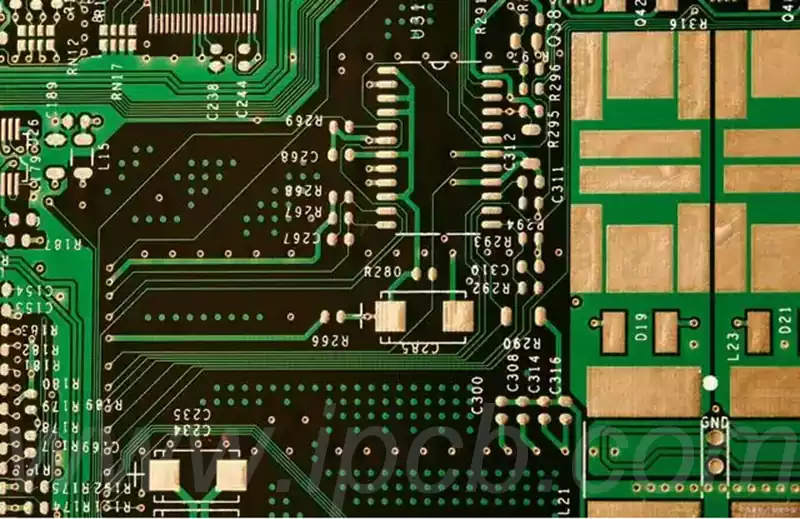

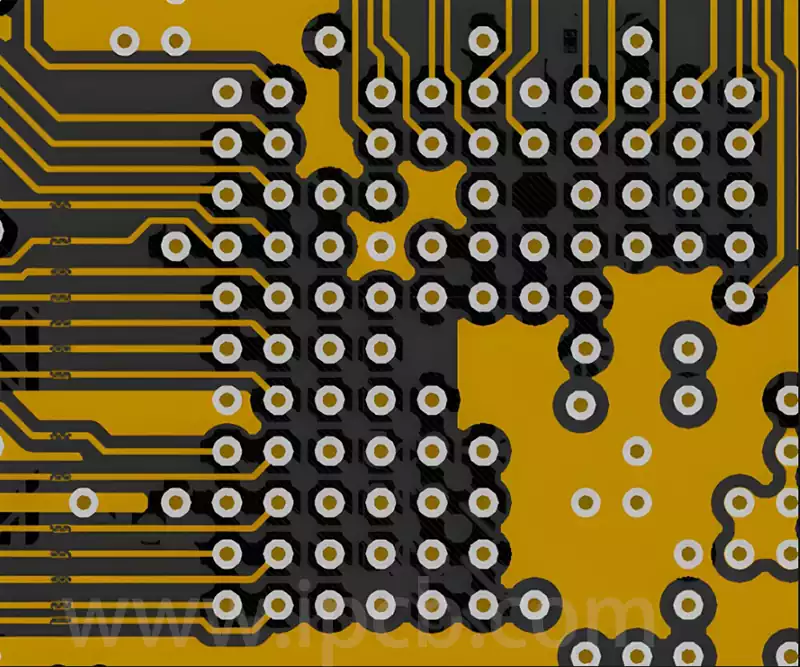

The I/O density of BGA packages is much higher than that of conventional DIP (Dual Inline Package) and QFP (Quad Flat Packages). This makes the BGA package particularly suitable for high-performance chips that require a large number of pins.

Electrical Performance

The solder balls of the BGA packages provide a shorter electrical path, which reduces signal transmission delays and noise and improves electrical performance.

Thermal Management

Due to the better thermal conductivity of the solder balls, the BGA packages outperforms other package forms in terms of thermal management, especially in higher power applications.

Reliability

Solder ball connections in BGA packages are more reliable than traditional pin connections because the solder balls can withstand greater mechanical stress.

Size and Weight

BGA packages can achieve more functionality in a smaller area than other package forms, which is especially important for portable devices and space-constrained applications.

Cost

Although BGA packages are relatively expensive to manufacture, their high I/O density and performance advantages make them more cost-effective in high-performance applications.

BGA packages on flexible circuit boards differ significantly from BGA packages on other types of circuit boards (e.g., rigid circuit boards) in terms of material selection, process flow, thermal management, and reliability, and these differences mainly stem from the mechanical properties and application requirements of the flexible circuit boards themselves:

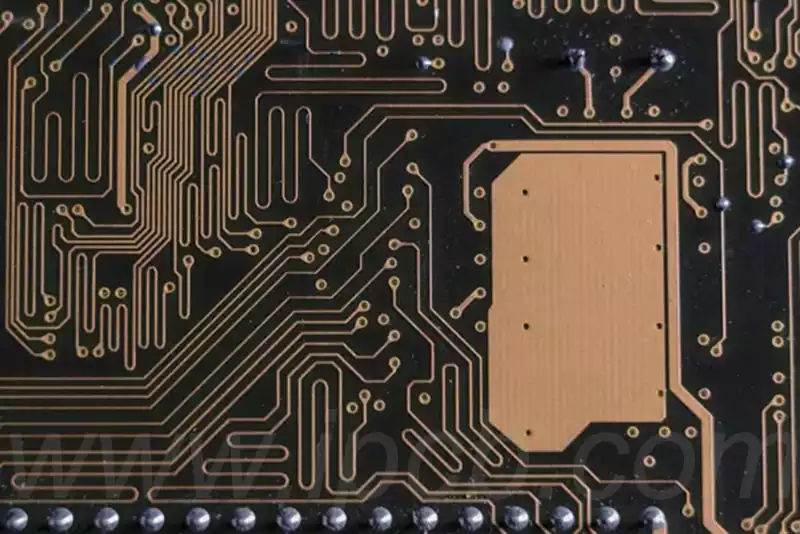

Flexible circuit boards use flexible materials such as polyimide (PI) and polyester film as substrates, which are bendable, thin and lightweight, and have good thermal performance. In contrast, rigid circuit boards mostly use glass fiber reinforced epoxy resin substrates (such as FR-4), which are more rigid but less flexible. This material difference directly affects the package design. Flexible boards need to ensure the integrity of the package layer in repeated bending and connection stability, while rigid boards are concerned about support strength and heat dissipation.

Soldering process adaptability

Flexible circuit boards due to the thermal sensitivity of the material, the soldering process is more stringent temperature control, the need to prevent deformation or damage to the substrate. In reflow soldering, flexible BGA packages utilize the self-alignment function of the solder balls to ensure precise alignment of the solder balls through surface tension, but the overall temperature profile needs to be optimized to protect the flexible substrate. BGA soldering of rigid boards is more tolerant of temperature and the process is relatively forgiving.

Package Carrier Differences

Flexible BGA packages usually use a flexible carrier tape (flexible substrate) as the package carrier, the carrier tape structure contains multi-layer polyimide wiring, with good thermal matching and flexibility. BGA packages on rigid circuit boards tend to use rigid multilayer copper-clad boards, focusing on electrical performance and thermal management.

Flexible BGA packages must withstand multiple folds and dynamic stresses, which places higher demands on the mechanical strength of the solder joints and the fatigue life of the substrate. Flexible substrates allow a certain degree of deformation, effectively reducing the stress generated by the mismatch of the coefficient of thermal expansion, but at the same time, the reliability of the design between the solder balls and wiring is more complex. Rigid PCBs, on the other hand, are usually subjected to static stresses only, and the design focuses on improving the matching of thermal expansion and the environmental resistance of the solder joints.

Flexible BGA packages typically have better thermal paths because the flexible substrate is thin and has short thermal paths, and the backside of the chip at the top of the package is directly exposed, which facilitates heat dissipation. Rigid PCB package heat dissipation depends on the thickness of the substrate and material thermal conductivity, heat dissipation design is more dependent on the design of the copper layer of the substrate and external heat dissipation structure. In terms of electrical performance, flexible BGA excels in high-speed signal transmission due to short solder ball connections and flexible wiring.

As a high-density, high-performance IC packaging technology, BGA packaging has become an important choice in modern electronic product design due to its superior I/O density, electrical performance and thermal management capabilities. Especially in the application of flexible circuit boards, BGA packaging by adapting to the unique material properties and mechanical requirements of the flexible substrate, to achieve excellent connection stability and heat dissipation, effectively meet the development trend of thin and light, flexible electronic equipment. Although its production process is relatively complex and costly, with the continuous progress of manufacturing technology and the improvement of testing methods, the advantages of flexible BGA packages will be further highlighted, promoting the development of electronic products to higher performance, smaller volume direction, opening up a smarter and more diversified application prospects.