EMI radiation consists of electric and magnetic fields, which disrupt the normal operation of electronic devices. These electromagnetic waves propagate within electronic devices and interfere with electrical components, with their ratio referred to as wave impedance. To reduce EMI, we use metal cans (Faraday cages) to encapsulate electronic circuits on printed circuit boards (PCBs), which is known as board-level EMI shielding.

EMI Basics and PCB-Level EMI Shielding Design Radiated EMI occurs when electromagnetic waves propagate in the direction of electronic equipment and disrupt the operation of the electrical component. Electromagnetic waves consist of an electric field (E) and a magnetic field (H), and the ratio of E to H (E/H) is called the wave impedance (Z). For air or free space, Zo = 377 Ω. Electromagnetic waves with impedance below this value are primarily magnetic, while those with impedance above this value are primarily electric.

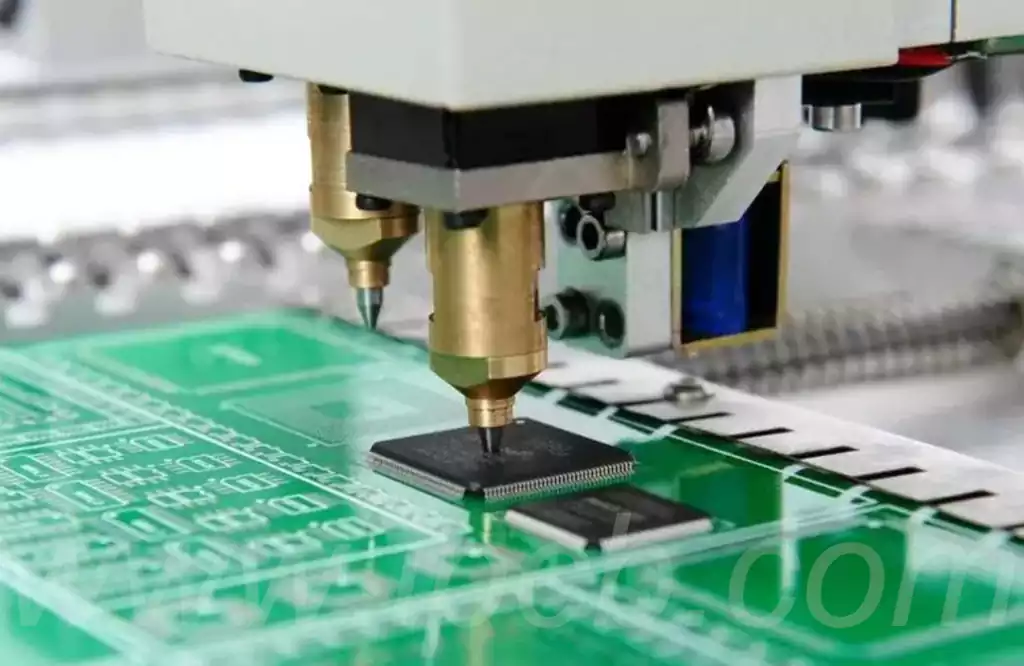

Using board-level shielding for EMI shielding means encapsulating electronic circuits on a PCB using a metal can (also known as a Faraday cage). This in turn limits the amount of EMI radiation from the external environment that could damage PCB components and reduces the amount of EMI energy generated by the circuit escaping into the external environment.

The efficiency of board-level emi shielding is measured by the shielding effectiveness (SE), which is the amount of EMI attenuation expressed in decibels (dB).

As shown in Figure 1, when electromagnetic waves come into contact with the shielding material, some energy is reflected, some is absorbed by the shielding material, and some energy passes through the material. Therefore, the total shielding effectiveness of EMI shielding is based on the sum of reflection and absorption losses.

Absorption loss depends on the physical properties of the emi shielding layer and is proportional to the thickness of the shielding layer, its relative permeability, the conductivity of the material, and the frequency of the electromagnetic waves.

Therefore, thick-walled shielding layers with high permeability and conductivity will perform well in terms of absorption loss. When suppression of emissions is required, such as when using a shielding layer to prevent electromagnetic energy from escaping from the enclosure, absorption loss is critical; see Figure 2.

PCB board-level EMI shielding design

Encapsulating electronic circuits on a PCB using a metal can (also known as a Faraday cage) is one method of EMI shielding. This method aims to limit electromagnetic interference (EMI) radiation from the external environment and prevent it from damaging PCB components. At the same time, it also reduces the escape of EMI energy generated by the circuit itself into the external environment.

Measuring Shielding Effectiveness

The efficiency of board-level shielding is assessed using the shielding effectiveness (SE) metric, which measures the attenuation of EMI in decibels (dB). When electromagnetic waves come into contact with shielding material, some energy is reflected, some is absorbed by the material, and some passes through the material. Therefore, the total shielding effectiveness of EMI shielding is based on the sum of reflection loss and absorption loss.

The Impact of Absorption Loss

Absorption loss is a key component of shielding effectiveness. This loss is directly related to the physical properties of the shielding layer, including its thickness, relative permeability, material conductivity, and the frequency of the electromagnetic waves. Generally, thick-walled shielding layers with high permeability and good conductivity excel in absorbing electromagnetic energy. Absorption loss is particularly important when suppressing electromagnetic emissions, such as preventing electromagnetic energy from leaking out of the enclosure.

The Impact of Reflective Loss

When PCB components need to resist the influence of electromagnetic waves from external sources, the role of reflective loss becomes critical. The magnitude of reflective loss depends on the degree of mismatch between the impedance of the electromagnetic wave and the impedance of the EMI shielding material. If the impedance of the electromagnetic wave differs from that of the EMI shielding layer, the electromagnetic wave will be partially reflected back. It is worth noting that when a high-impedance electric-dominant incident wave (impedance greater than 377 Ω) comes into contact with a low-impedance highly conductive metal, it results in high reflection loss. However, for a low-impedance magnetic-dominant incident wave (impedance less than 377 Ω), the impedance mismatch between the shielding layer and the wave is small, resulting in very low reflection loss. In this case, absorption loss is critical for shielding the magnetic field.

How to implement an effective EMI shielding solution for a six-layer PCB:

- Add a signal layer

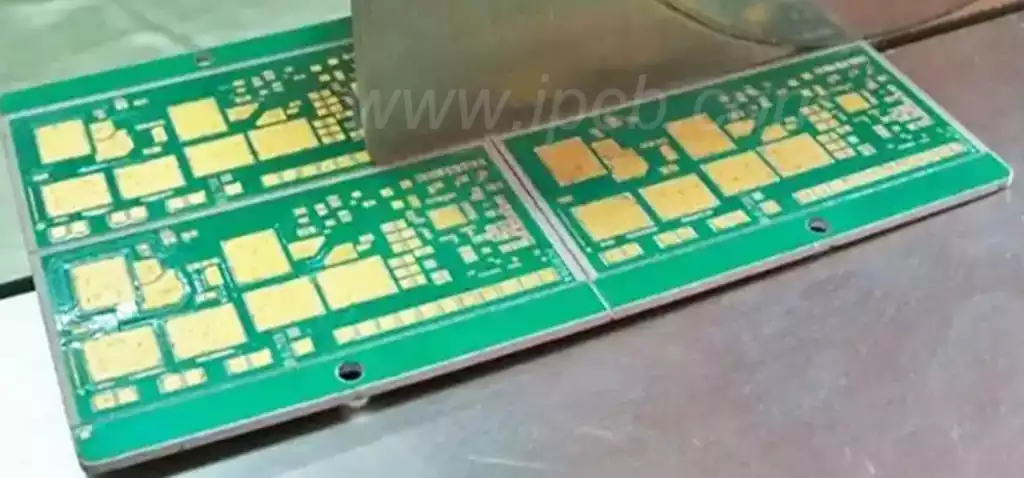

On the basis of a standard six-layer board, add a half-signal-line layer specifically for routing critical signal lines, aiming to minimise mutual interference between signals. To ensure signal integrity, the signal lines on this layer should be as short and straight as possible, avoiding unnecessary bends and crossings. For example, differential microstrip lines on the outer layers can be transferred to inner layer striplines via blind vias to optimise the design. - Optimise Power and Ground Layer Layout

Power layers and ground layers are typically placed on the outer layers of the PCB stackup to form effective electromagnetic shielding. In multi-layer board designs, there are generally two power layers and two ground layers. In the intermediate layers, power and ground layers should be arranged reasonably to ensure that each signal layer is adjacent to an inner power layer, avoiding direct adjacency between signal layers to effectively reduce interlayer signal crosstalk. For example, in a six-layer board, the spacing between power planes and ground planes should be minimised to shorten the distance between signals and reference planes, thereby optimising EMI. Additionally, power planes and ground planes should follow a symmetrical principle to ensure uniform current distribution, reduce power impedance, stabilise voltage supply, and minimise the impact of voltage fluctuations on the circuit. Furthermore, placing ground traces alongside critical signal traces and ensuring they are as short as possible also helps reduce interference. - Local copper plating and grounding

In PCB design, for idle areas without components or traces, local copper plating can be applied, also known as copper filling. The purpose of copper plating is to increase the current-carrying area, enhance current-carrying capacity, and strengthen the PCB’s interference resistance. These copper-plated areas must be connected to the internal ground plane or power plane via multiple points. The distance between connection vias should be less than 1/20 of the highest harmonic wavelength of the signal to ensure good grounding performance. In high-frequency circuits, if copper plating grounding is poor, the copper-plated area may instead become a pathway for noise propagation. Therefore, holes must be drilled in the traces, with a spacing of less than 𝜆/20, to ensure ‘good grounding’ with the ground plane of the multilayer board. - Use of High-Frequency Materials

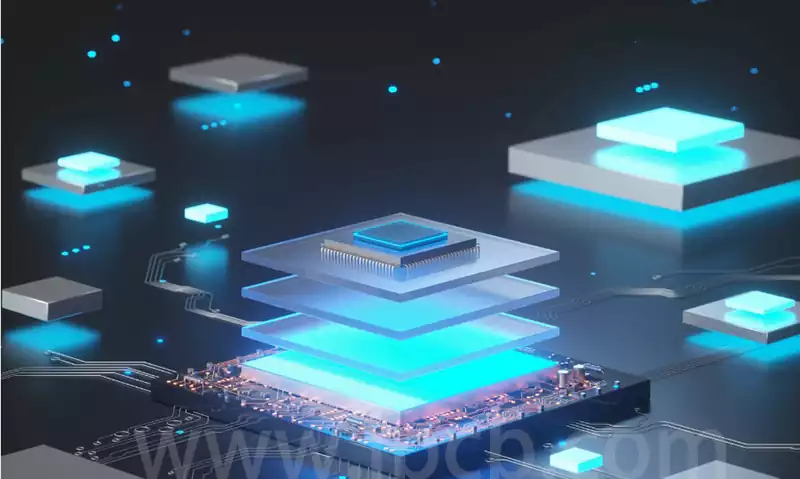

Selecting materials with excellent high-frequency characteristics is critical, such as low loss (low dielectric loss Df) and low dielectric constant (Dk) materials. These materials effectively reduce signal loss and distortion during transmission. Common high-frequency PCB materials include polytetrafluoroethylene (PTFE), epoxy resin (EP), and bismaleimide triazine resin (BT). - Add shielding layers

In multi-layer PCB designs, additional shielding layers can be considered to isolate critical signal areas, preventing external electromagnetic interference and reducing internal EMI. Shielding layers should be connected to ground planes to form a continuous electromagnetic shielding network, effectively blocking electromagnetic fields from both external and internal sources. For critical signal lines such as clocks in high-speed PCB designs, shielding can effectively prevent EMI leakage. - Optimise routing strategies

Using differential pair routing strategies is an effective method to reduce crosstalk between signals. The positive and negative sides of a differential signal pair must always be transmitted along the same path in the same environment and remain closely adjacent to each other, allowing the signals to couple through electromagnetic fields and thereby reduce EMI emissions. For high-speed signals, microstrip or stripline structures should be used to improve signal transmission quality and interference resistance. - Strictly control impedance

In multi-layer PCB design, strictly controlling the impedance of signal lines is critical to ensuring signal transmission stability and consistency. PCB impedance control refers to controlling the impedance of traces, which is also known as controlled impedance. It is the characteristic impedance of the transmission line formed by the PCB traces and their associated reference planes. By adjusting parameters such as trace width, trace spacing, and dielectric thickness, impedance can be precisely controlled. Designers can use impedance calculation tools, such as Polar SI9000 or HyperLynx, to calculate the ideal impedance values.

In complex electronic device designs, effective EMI control is critical. By implementing board-level EMI shielding and fine-tuning the multilayer PCB stackup structure, we can significantly enhance the product’s electromagnetic compatibility.