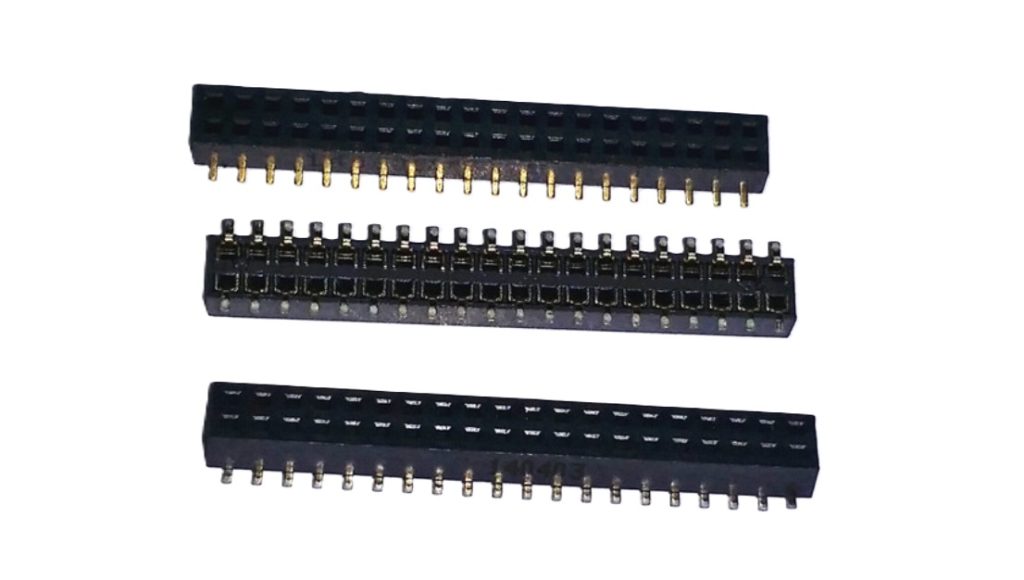

Board-to-board PCB connectors are miniature coupling plugs and sockets that allow direct connection of power and signals between printed circuit boards through the pins of the connector. In order to prevent the board-to-board PCB connector from oxidizing to reduce conductivity, copper alloy materials are generally used.

The role of board-to-board PCB connectors:

- In electronic manufacturing, the entire device may need to fit the available space, because if the circuit board design stage of the PCB tends to take up too much space, the device may be divided into two or more boards. Board-to-board pcb connectors can make all the connections by connecting power and signals between boards.

- Board-to-board PCB connectors can simplify the circuit board design process. Smaller PCBs often require manufacturing equipment that can’t accommodate larger PCBs, and power consumption needs to be taken into account whether devices are squeezed into a single PCB or multiple PCBs.

- In addition, the use of board-to-board PCB connectors also simplifies the production and testing of electronic devices. Simplified testing in the electronics manufacturing industry reflects significant cost savings. High-density PCB per unit area with more traces and components, equipment or products are best designed to have several interconnected medium-density board rather than a single high-density board.

Classification of board-to-board PCB connectors:

- Spring-loaded connector

It consists of two parts, a plug and a socket. There are small springs on the plug which form a tight connection between the plug and the socket. This type of connector is often referred to as a spring clamp connector. The advantage is that it is easy to install and remove and provides a reliable connection, even when moving or vibrating. - Plug type connector

These connectors are very similar to spring-loaded connectors, but they use a locking mechanism to hold plugs and sockets more securely. These connectors provide a more reliable connection, but are more complicated to install and remove. - Pin Type Connectors

This type of connector creates a permanent connection on the PCB. This is because the pins of this connector are actually soldered to the PCB. This type of connector provides the most stable connection and is able to withstand extreme conditions such as high temperatures and high pressures, and is also more suitable for high-end electronic devices and computers. - Crimp connectors

This type of connector allows the connector pins to be soldered without the need for soldering to the PCB board. Instead, it inserts the pin pins into holes on the PCB and then completes the connection by crimping. While these connectors may not be as stable as spring-loaded connectors when moving or vibrating, they are very easy to use and are more time and labor efficient. In addition, these connectors do not have temperature effects.

The main benefits of board-to-board PCB connectors include high-speed data transfer capability, miniaturized size, reliability and flexibility. These connectors are well suited for use in panel-based electronic devices such as smartphones, tablets, digital cameras, laptops, smartwatches, and other devices. For example, the camera, antenna, light sensor, touch screen and other components in smartphones require the use of board-to-board PCB connectors for signal transmission and power supply.

How to choose the parameters of the board-to-board PCB connector?

- Pay attention to the pin and pitch

The number of pins, pin spacing is the basic basis for connector selection. Select how many pins of the connector should be based on the number of signals connected to the number of pins for some SMD connectors should not be too many pins. Because in the SMD welding process due to the role of high temperature connector plastic will be deformed by heat, the center of the bulge caused by the pin soldering. - Pay attention to the electrical properties

Electrical properties of the connector mainly include: limit current, contact resistance, insulation resistance and electrical strength. Connection of high-power power supply need to pay attention to the limit current of the connector; transmission of high-frequency signals such as LVDS and other signals need to pay attention to the contact resistance. Connector usually has a low and constant contact resistance, generally tens of mΩ to hundreds of mΩ. - Pay attention to environmental performance

Selected according to the specific application environment. If the application environment is more humid for the connector’s moisture resistance, salt spray resistance requirements are high, to ensure that the connector’s metal contacts are not corroded. In the field of industrial control on the connector vibration shock performance requirements are high, so as to avoid the connector in the vibration process to fall off. - Pay attention to the mechanical properties

Mechanical properties of the connector, including the pull-out force and mechanical anti-dumbness. Mechanical dummy connector is very important, once inserted in reverse is likely to cause irreversible damage to the circuit.

Board-to-board PCB connectors are essential connectors in modern electronic equipment and systems. They are designed and manufactured to improve the performance and reliability of equipment, while also bringing consumers smaller, more convenient and efficient electronics. In the future, these connectors will continue to play an even more important role as we live and work more and more without electronic devices and networks.