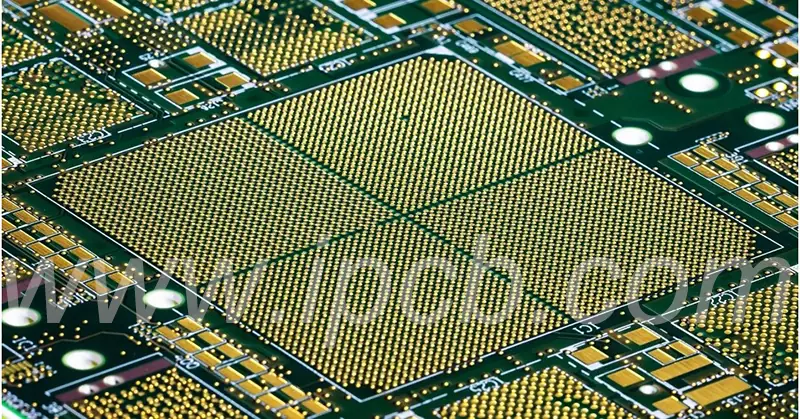

Electroplating copper is a thin film of copper plated on the surface of other materials, usually by electrolytic deposition. Pure copper is a material made entirely of copper, and the higher the purity, the better the electrical properties.

Electroplating is the process of plating a thin layer of a specific metal or alloy on a specific metal surface using the principle of chemical electrolysis. Acid copper plating is also called β-anode method of copper plating, plating, plating metal Cu for the anode, the anode Cu get two electrons are oxidized into cations into the plating solution; PCB board for the metal products to be plated as the cathode, plating solution in the Cu2 + cations in the Cu metal surface of the PCB board to lose two electrons are reduced to form Cu.

Copper plating layer has good electrical conductivity, thermal conductivity and mechanical ductility and other advantages, is the printed circuit board (PCB) manufacturing indispensable key plating technology.

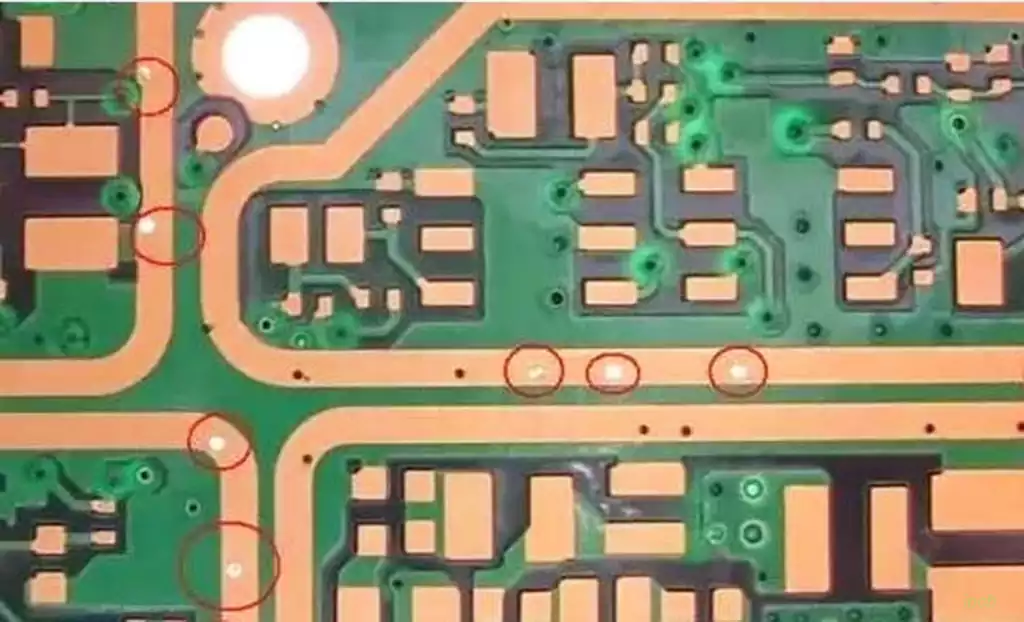

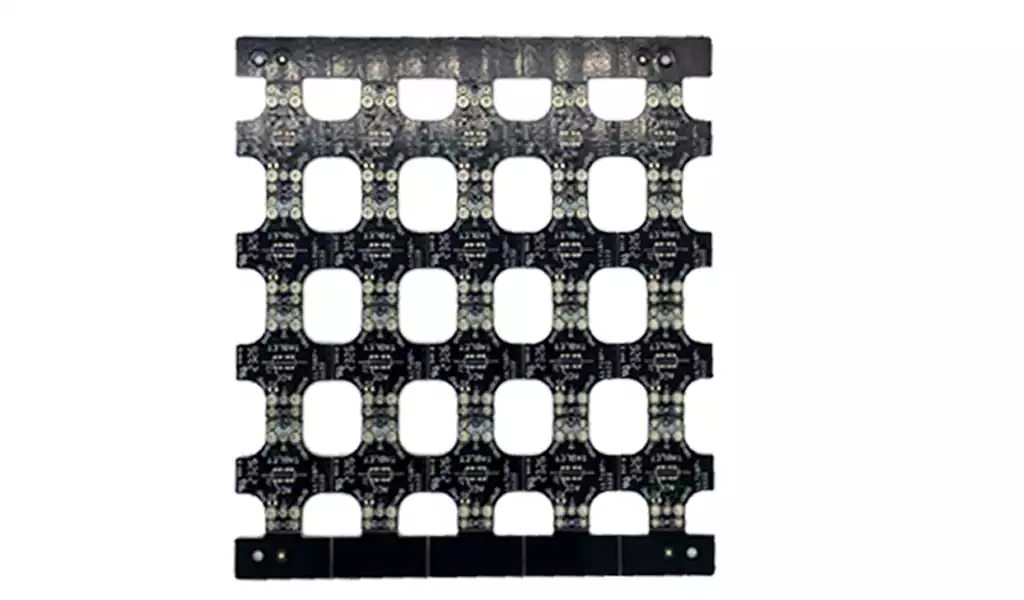

Printed circuit board electroplating copper has a full plate copper plating, graphic line copper plating and copper plating of microvia production, etc., commonly used plating solution has sulfate plating solution, pyrophosphate plating solution and cyanide plating solution, and is more commonly used is the acid sulfate plating solution.

How to electroplate copper

Electroplating copper is an electrochemical process that usually involves the following steps:

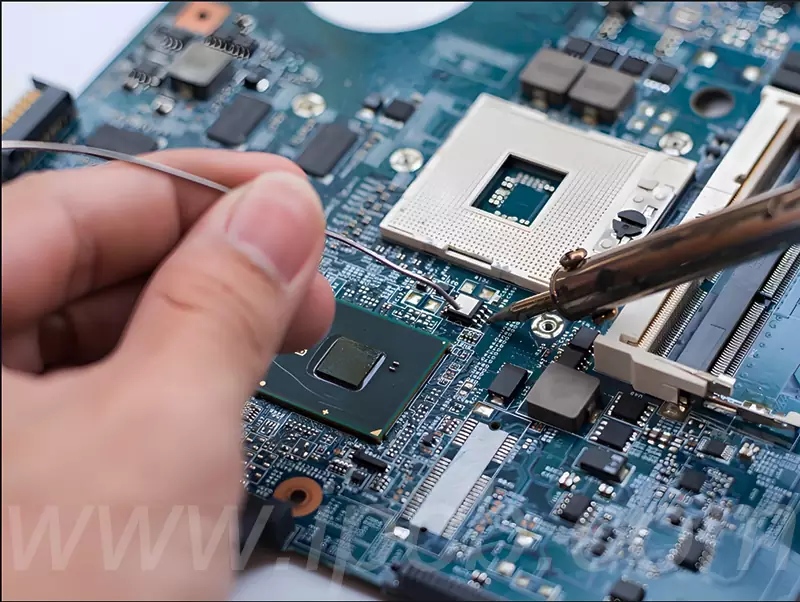

Prepare the metal to be plated. The metal surface is first cleaned to remove oil, rust and oxides, which can be accomplished by methods such as chemical cleaners or mechanical abrasion.

Prepare the plating solution. Depending on the plating method, the plating solution can be acidic or alkaline, and can contain copper salts, acids, alkalis, or organic compounds.

Prepare power supply and clamps. Prepare a power supply (e.g., cell phone charger or computer charger) and clamps to ensure that the voltage of the power supply is suitable for copper plating.

Plating. Immerse the prepared metal products in the plating solution and connect them to the negative electrode (cathode) of the power supply, and connect the copper products to be plated to the positive electrode (anode) of the power supply.

Observation and adjustment. During the plating process, observe the changes in the metal surface and adjust the current, temperature, plating solution concentration and other parameters as needed.

Post-processing. After plating is complete, the metal product is removed from the plating solution and rinsed to remove any residual plating solution or dirt, and sometimes polished and cleaned to obtain a bright and smooth surface.

It is important to note that the chemicals used in the copper plating process can be harmful to the human body and the environment, so it is important to operate with safety in mind and to ensure that waste is disposed of properly to prevent contamination.

The main steps and points in the formulation and production of copper electroplating solution

- Copper salt solution

Copper salt solution is the main electronic component of copper plating solution, usually using copper sulfate or copper chloride as the copper source. Dissolve a certain amount of copper salt in water to prepare a certain concentration of copper salt solution. - Acidifying agent

Acidifying agent usually adopts sulfuric acid or hydrochloric acid as the acidity regulator, used to adjust the pH value of the copper salt solution. A certain amount of acidifier is added to the copper salt solution to control the pH of the solution. - Buffer

Buffer is a kind of additive that can resist the change of solution pH value. In the copper plating solution, the use of a certain amount of buffer can maintain the stability of the solution pH, to ensure the stability of the plating process. - Plating aid

Plating aid is a kind of additive that can promote the precipitation of metal ions on the electrode. In the copper plating solution, using a certain amount of auxiliary plating agent can promote the precipitation of copper ions on the electrode to improve the plating efficiency. - Other additives

In addition to the above main components, copper plating solution can also add some other additives, such as wetting agents, brightening agents, stabilizers, etc., in order to improve the plating effect and processing performance. The type and dosage of these additives depend on the actual needs.

Copper electroplating solution production process

- Dissolve a certain amount of copper salt in water to prepare a certain concentration of copper salt solution.

- Add appropriate amount of acidifier to adjust the pH of the solution as needed.

- Add an appropriate amount of buffer to maintain the stability of the pH of the solution.

- Add appropriate amount of auxiliary plating agent as needed to promote the precipitation of copper ions on the electrode.

- Add an appropriate amount of other additives, such as wetting agent, brightener, stabilizer, etc., as needed.

- The prepared copper plating solution is filtered and decontaminated to ensure the purity and transparency of the solution.

Electroplating copper plays a key role in the manufacture of printed circuit boards, but we must also be aware that the chemicals used in the electroplating process can pose a potential threat to humans and the environment. Therefore, it is important that we follow strict safety regulations during the process and ensure that waste is disposed of properly to prevent environmental contamination.