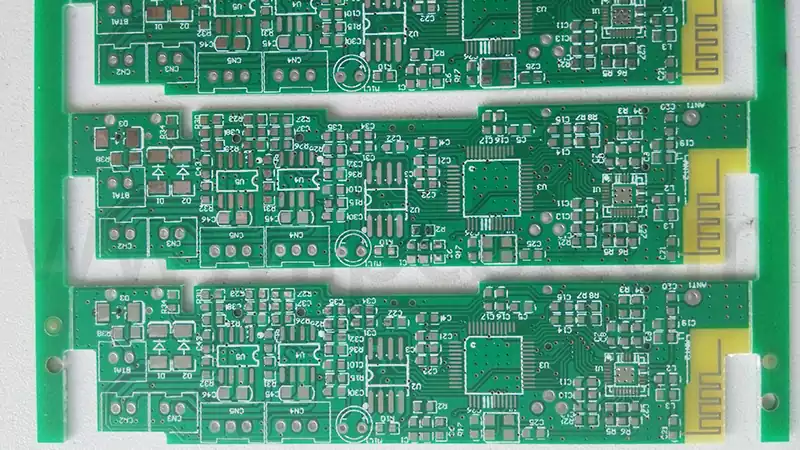

Burn in board is a common test method to evaluate the performance and reliability of circuit boards by simulating the conditions of long-time use or harsh environments. The circuit board aging process is the specific steps and procedures to carry out circuit board aging test. In practice, the standardisation and optimisation of the circuit board aging process is very important to improve the accuracy and efficiency of the test, but also to reduce the losses caused by improper operation.

PCBA burn in test standards:

Low-temperature work: put the PCBA board in the temperature of -10 + 3 ℃ for 1 hour, with a rated load, under the condition of 187V and 253V power to run all the programmes, the programme should be correct. High temperature work:Put the PCBA board under the temperature of 80+3’℃ for 1 hour, with load, under the condition of 187V and 253V power to run all the programmes, the programme should be correct. High temperature and high humidity work: the PCBA board at a temperature of 65 ± 3 ℃. Humidity 90-95% of the conditions, time 48 hours, with a rated load power to run the program, the program should be correct.

Burn in board performance test standards:

Temperature cycling: the circuit board in the 060 ℃ or 1060 ℃ temperature range for the cycle, the rate of change in temperature is generally 1 + 0.5 ‘Cmin, thermal aging time of at least 72 hours at each temperature point to maintain a certain period of time, at the specified rate of temperature rise and fall until the specified aging time. Appearance inspection: Visual inspection of all circuit boards to be aged, eliminating circuit boards with obvious defects, such as short circuits. Broken circuit. Component installation error. Missing parts, etc. Electrical parameter testing: Electrical parameter testing of circuit boards, eliminating boards with parameters that do not meet the requirements.

Common burn in test methods:

Thermal burn in test: Place the product in a high-temperature environment to simulate the use of the product in high-temperature conditions. By testing the product in the high temperature environment performance changes, such as electrical properties. Mechanical properties, etc., to assess the heat resistance and stability of the product. For example, for electronic equipment, it can be placed in a high-temperature chamber, set different temperatures and time, and then test the changes in its electrical properties.

Wet burn in test: Place the product in a humid environment to simulate the use of the product under humid conditions. By testing the product’s performance changes in the humid environment, such as electrical performance. Mechanical properties, etc., to assess the moisture resistance and stability of the product. For example, for electronic equipment, it can be placed in a humid box, set different humidity and time, and then test the change of its electrical properties.

Salt Spray burn in test: Place the product in a salt spray environment to simulate the use of the product in a marine environment or coastal area. By testing the product’s performance changes in the salt spray environment, such as electrical performance. Mechanical properties, etc., to assess the salt spray resistance and corrosion resistance of the product. For example, for automotive parts, you can place them in a salt spray test chamber, set different salt spray concentrations and time, and then test their surface corrosion and changes in electrical properties.

Light burn in test: Place the product in a light environment to simulate the use of the product under direct sunlight or UV radiation. By testing the product’s performance changes in the light environment, such as colour changes. Mechanical property changes, etc., to assess the light resistance and stability of the product. For example, for plastic materials, it can be placed in the light test chamber, set different light intensity and time, and then test its colour change and mechanical property change.

Mechanical burn in test: By applying mechanical stress to the product, such as vibration. Shock. Friction, etc., to simulate the mechanical damage that the product may suffer during the actual use, in order to assess the mechanical durability and reliability of the product. For example, for automotive parts, vibration testing. Shock test, etc., in order to detect its performance changes under different mechanical stress.

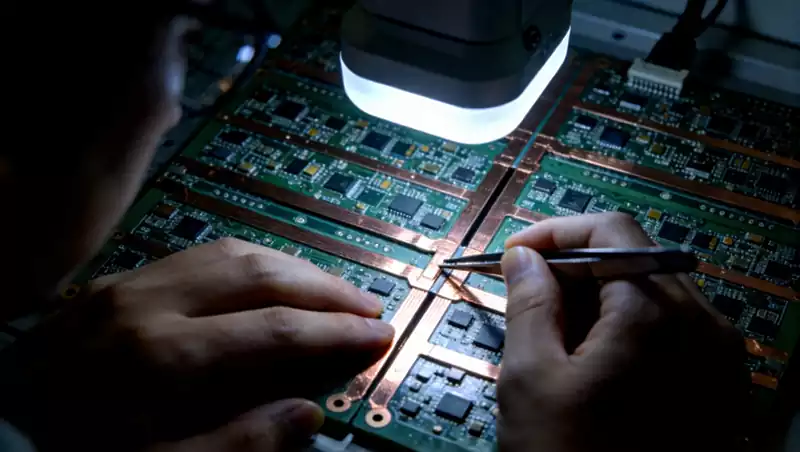

Circuit board burn in test workflow

- Preparation of the burn in test room

First of all need to prepare a special aging room, it is recommended that the aging room temperature. Stable humidity, the temperature is usually set at about 60 ℃, humidity is set at about 70%, while ensuring that the room is well ventilated. - Select burn in test tools

Choose to use the aging box or desktop aging equipment, to ensure that the selected aging equipment has accurate temperature control and humidity control function. - Prepare burn in test samples

According to the number of circuit boards to be aged, prepare sufficient test samples and number them. - Aging conditions

According to the purpose and requirements of the aging experiment, set the aging conditions, mainly including aging time. Temperature and humidity and other parameters. Usually the aging time lasts about 48 hours, and the specific settings of temperature and humidity depend on different aging purposes. - Putting the test sample into the aging test equipment

Place the test samples into the aging equipment and arrange the test samples according to the layout of the aging apparatus to ensure that the test samples are subjected to the same aging conditions. - Burn In Test Data Recording

During the aging experiment, you need to record the aging time, temperature and humidity of the test samples. Temperature and humidity data for subsequent data analysis and report generation.

Burn in test process control points

- Place the circuit boards evenly in the aging equipment to ensure that each circuit board can be evenly heated.

- Strictly in accordance with the set temperature and time for aging, during which the equipment should be regularly checked to ensure the safety and stability of the aging process.

- During the aging process, pay close attention to the state of the circuit board, if there are abnormalities should immediately stop aging and check.

Burn in board test is an important means of assessing product quality, but also an indispensable quality assurance step in the electronic manufacturing process. Circuit board aging test as a guarantee of electronic product quality and reliability of an important link, need to strictly follow the standardised operating procedures and unified performance test standards.