Role of Automatic Test Equipment

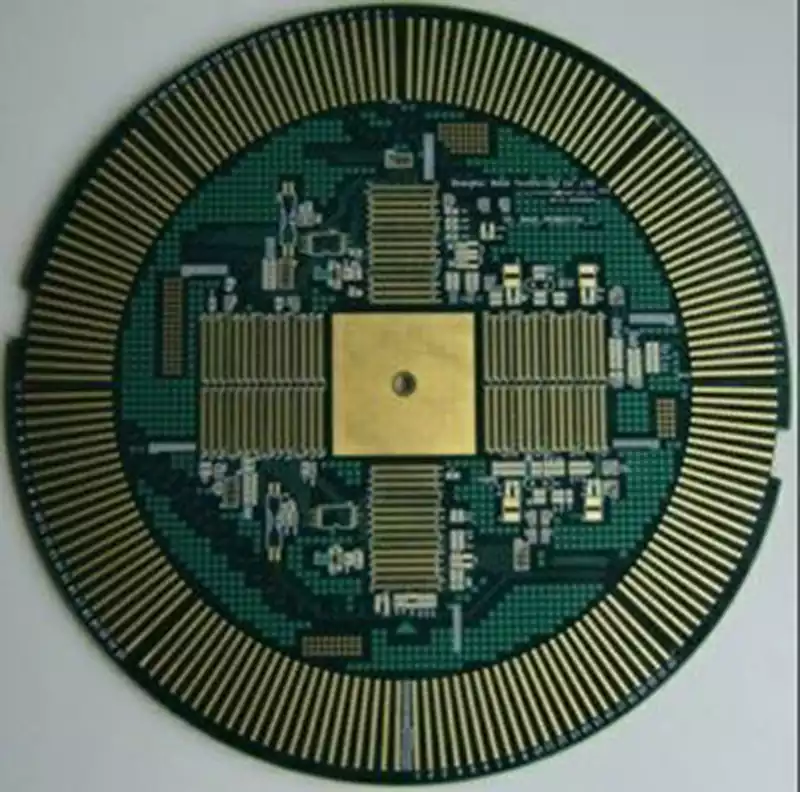

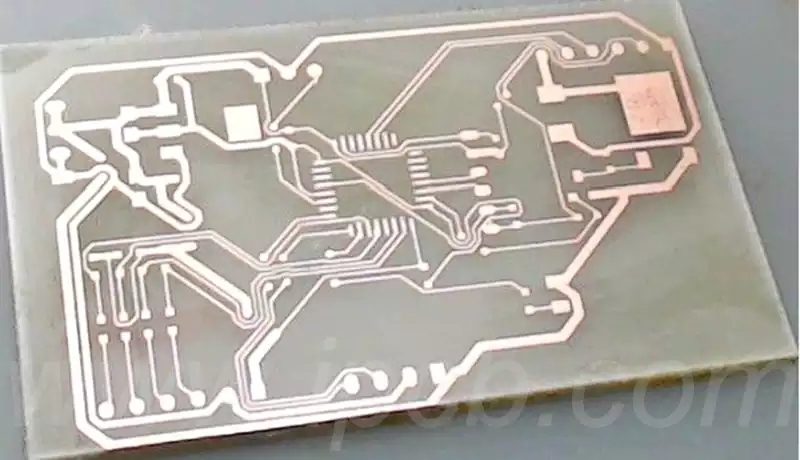

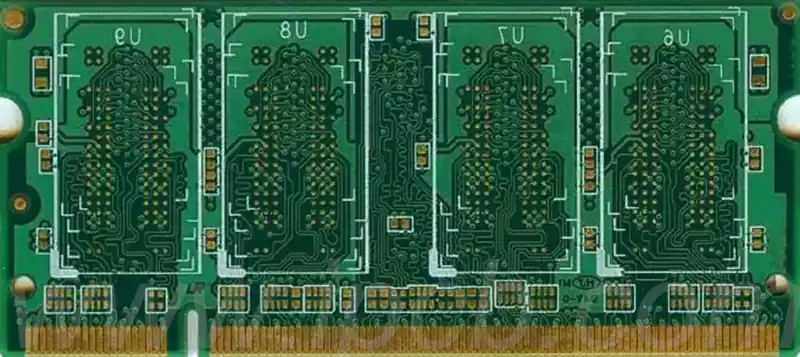

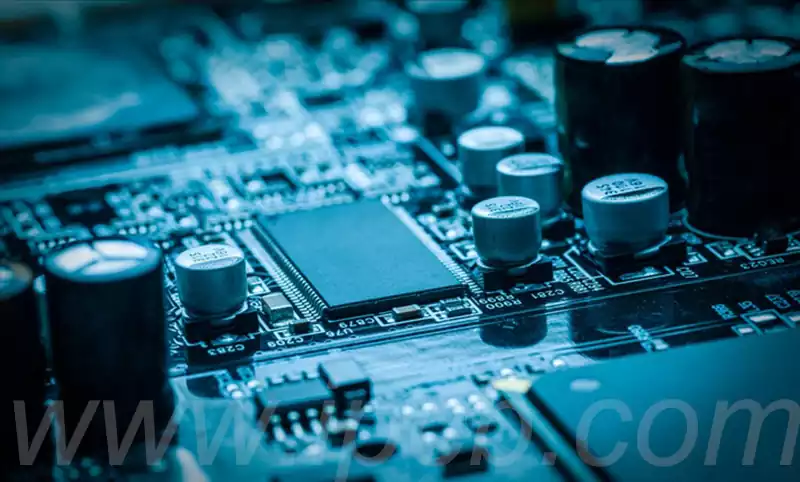

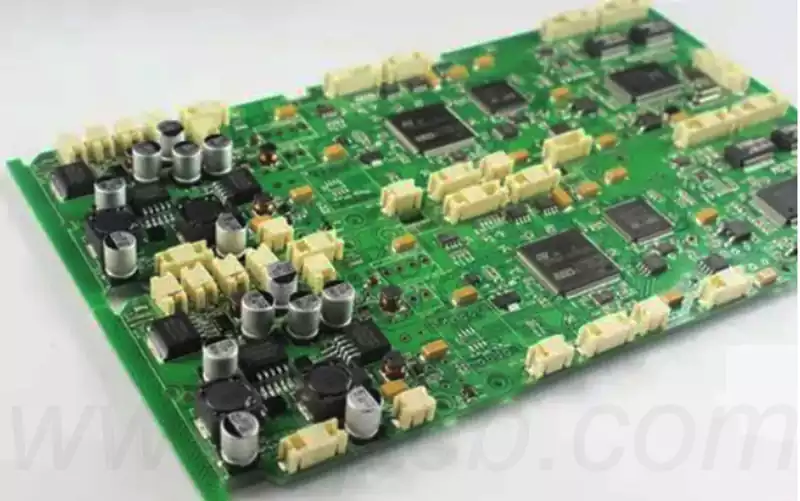

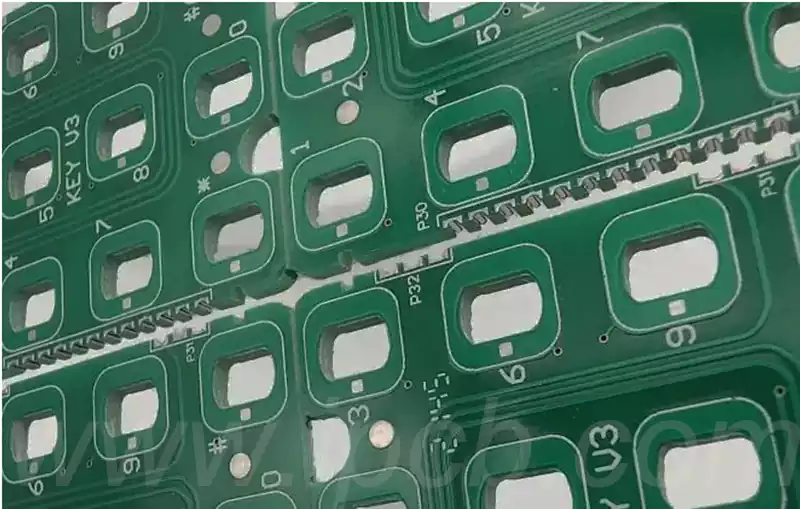

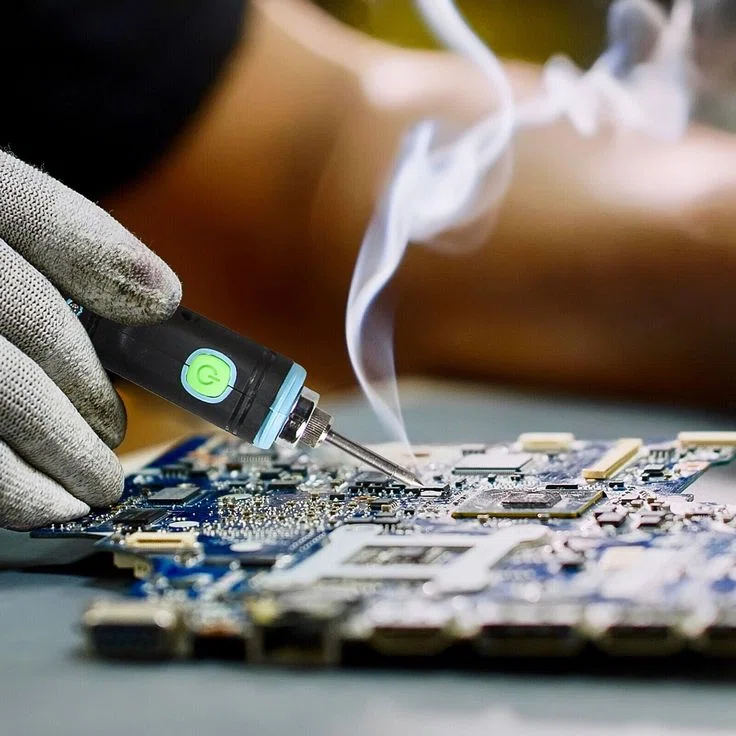

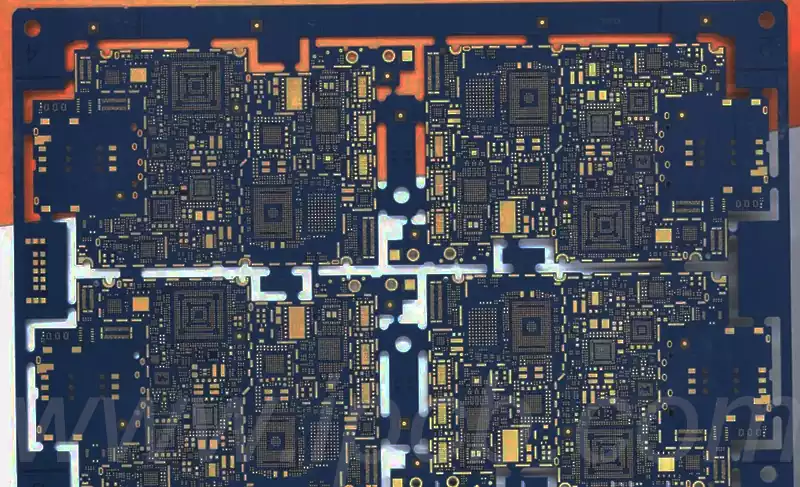

Semiconductor test boards, or ATE (Automatic Test Equipment) as we often call them, are an essential part of the semiconductor industry. Semiconductor test boards are specialised circuit boards used to evaluate, verify and test the performance of semiconductor devices. These test boards are precision designed to accommodate different types of semiconductor devices and to accurately […]