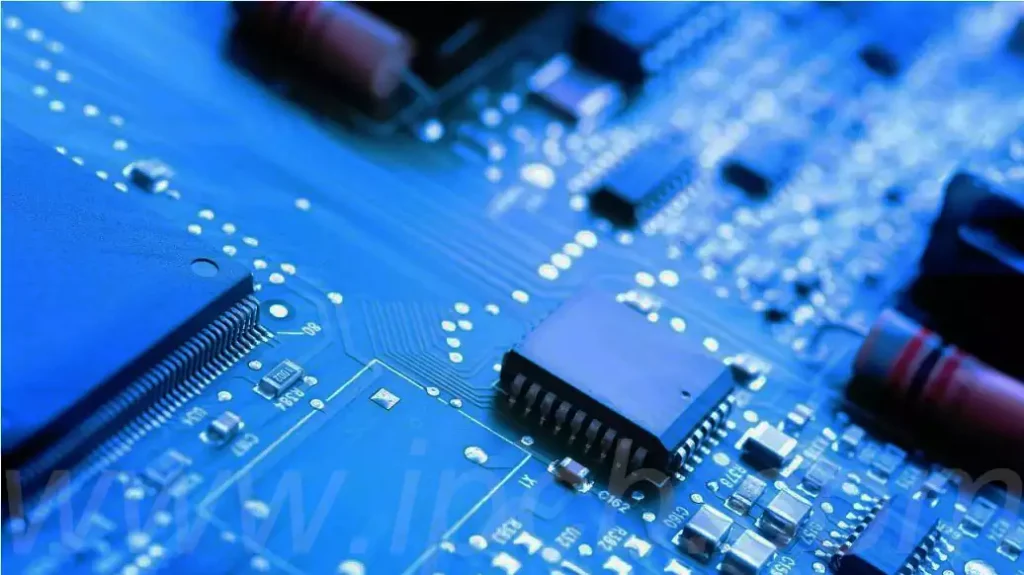

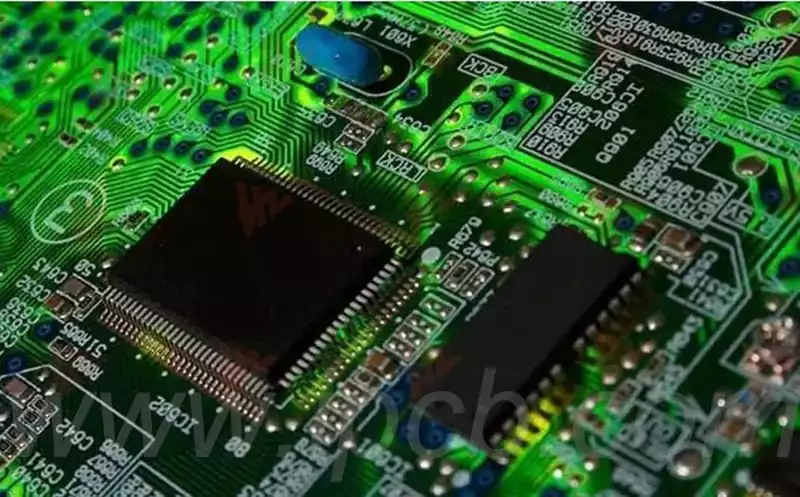

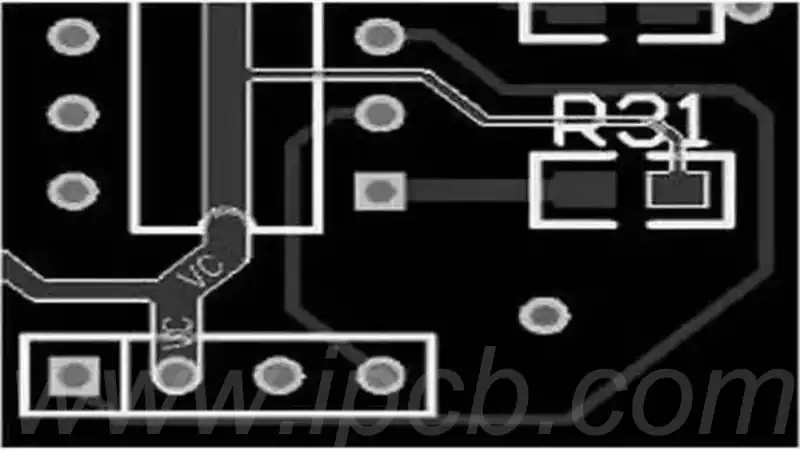

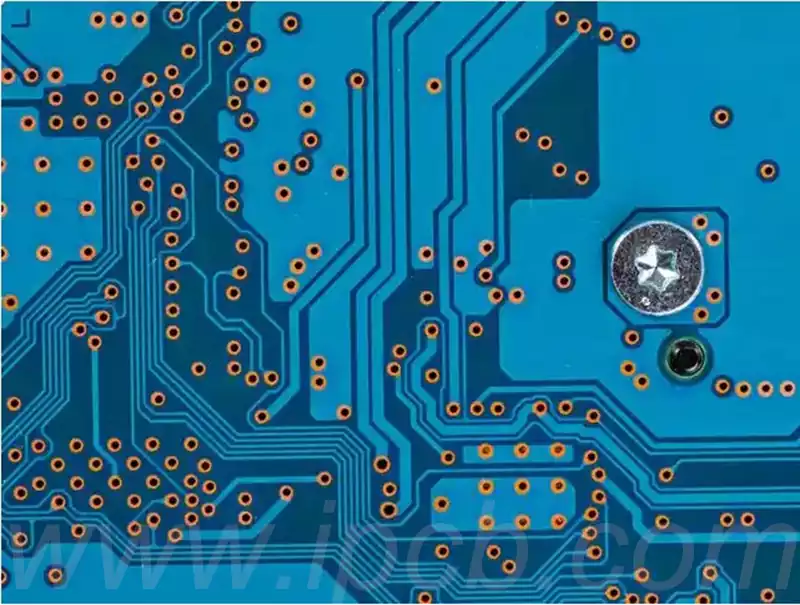

IC Board Component Layout Optimisation

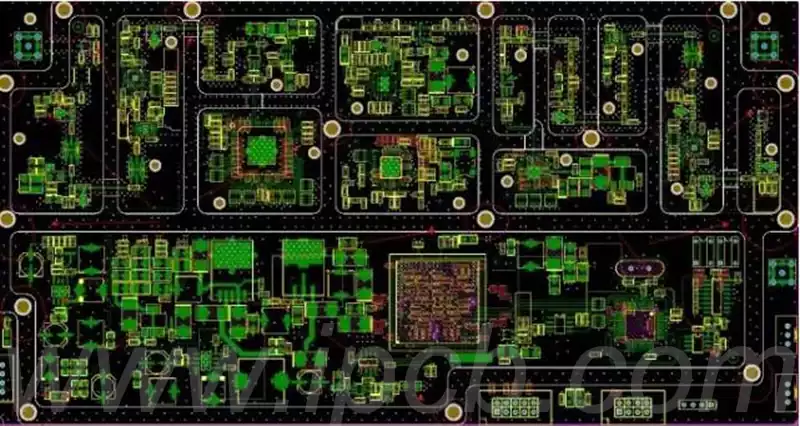

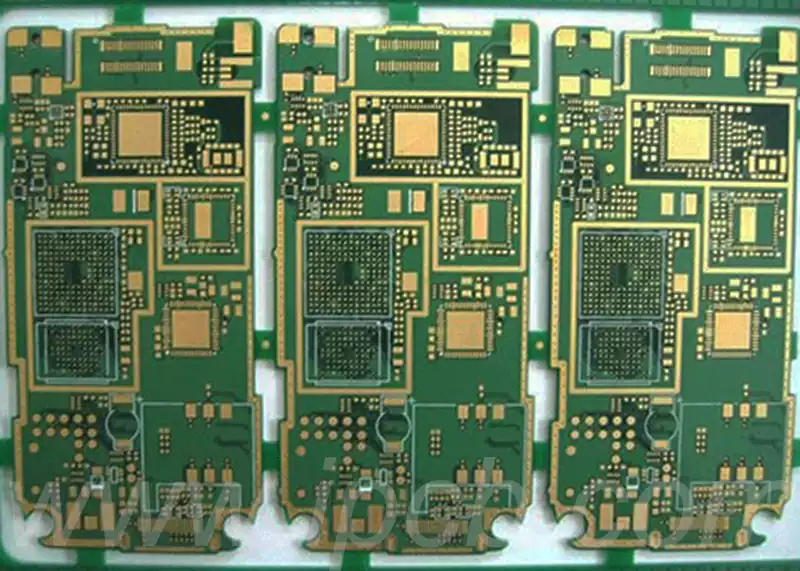

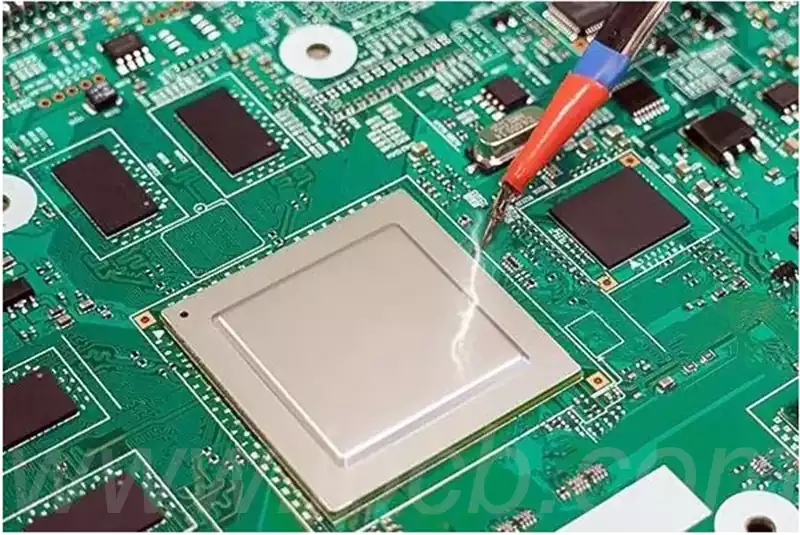

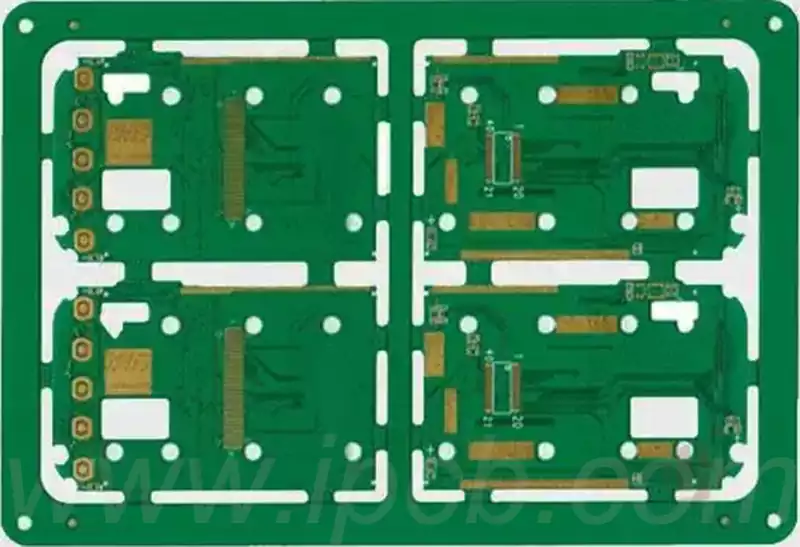

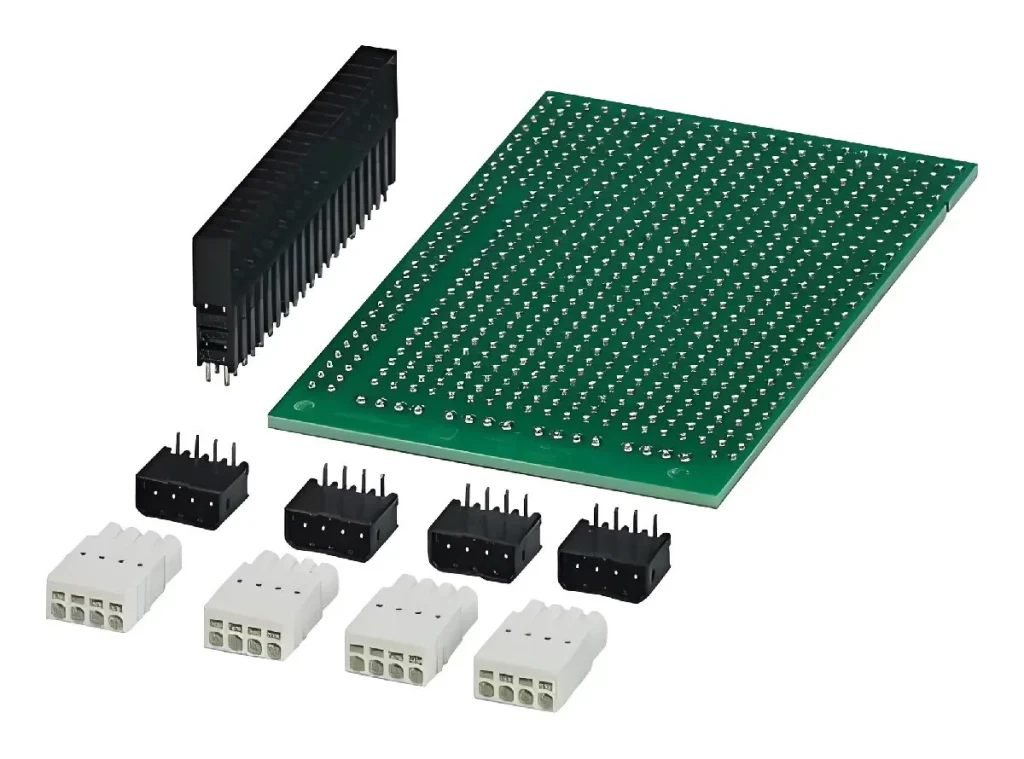

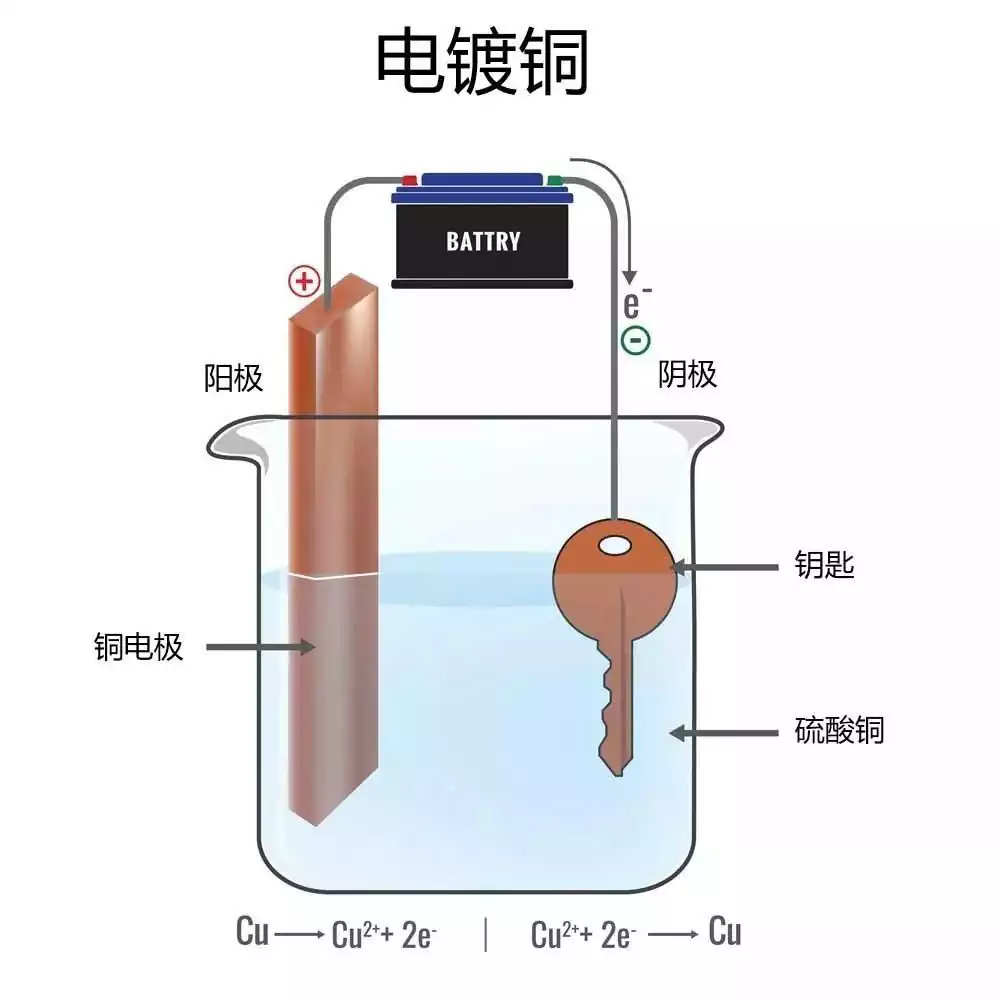

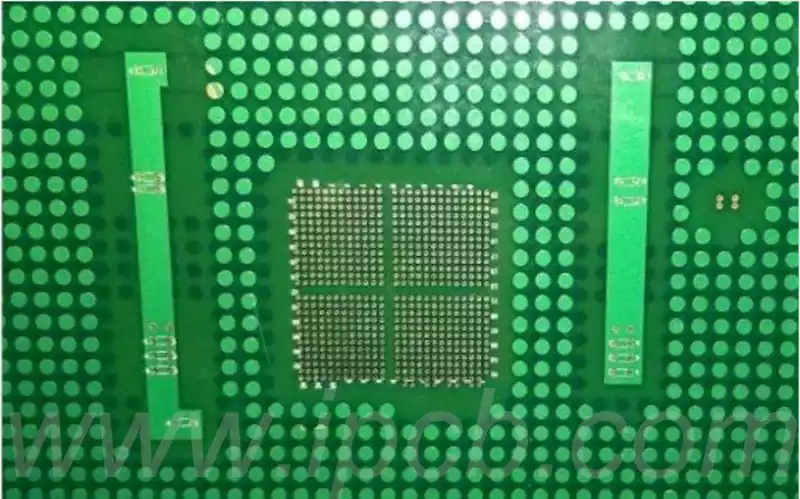

As a core component, the design and layout of an integrated circuit board (IC board) has a direct impact on the performance, reliability, and productivity of the device.The layout of IC board components not only needs to meet the requirements of electrical performance, but also needs to take into account various factors such as manufacturing […]