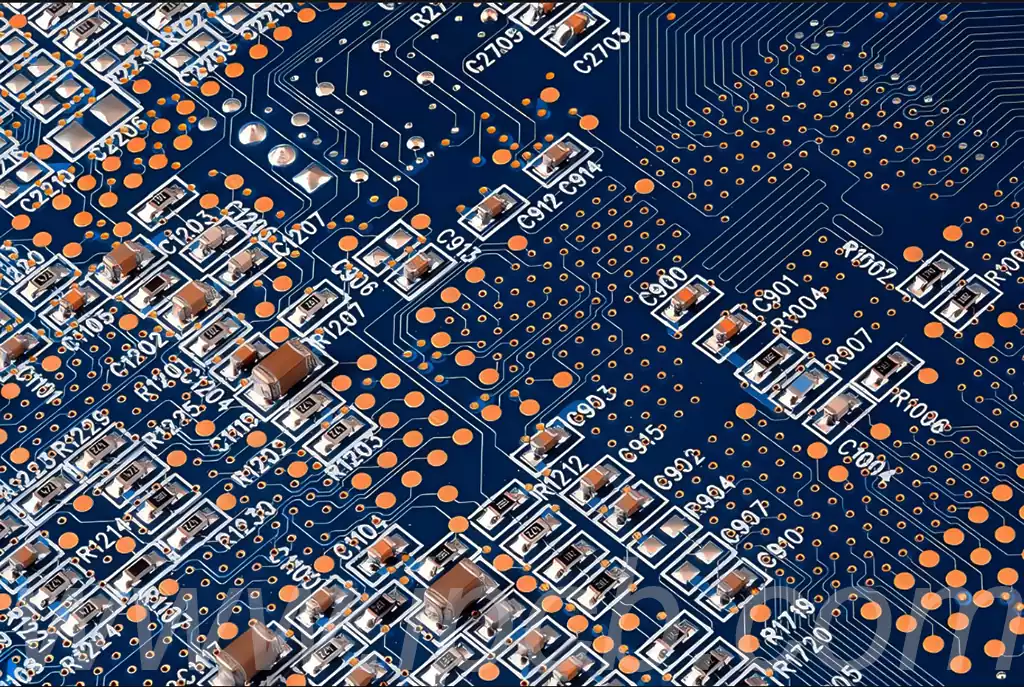

PCB Copper Layup Technology Enhances PCB Board Performance

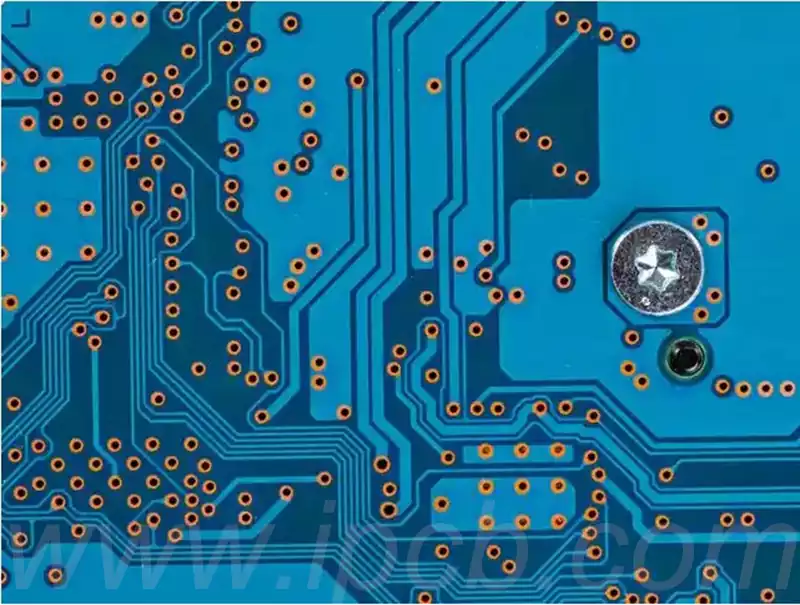

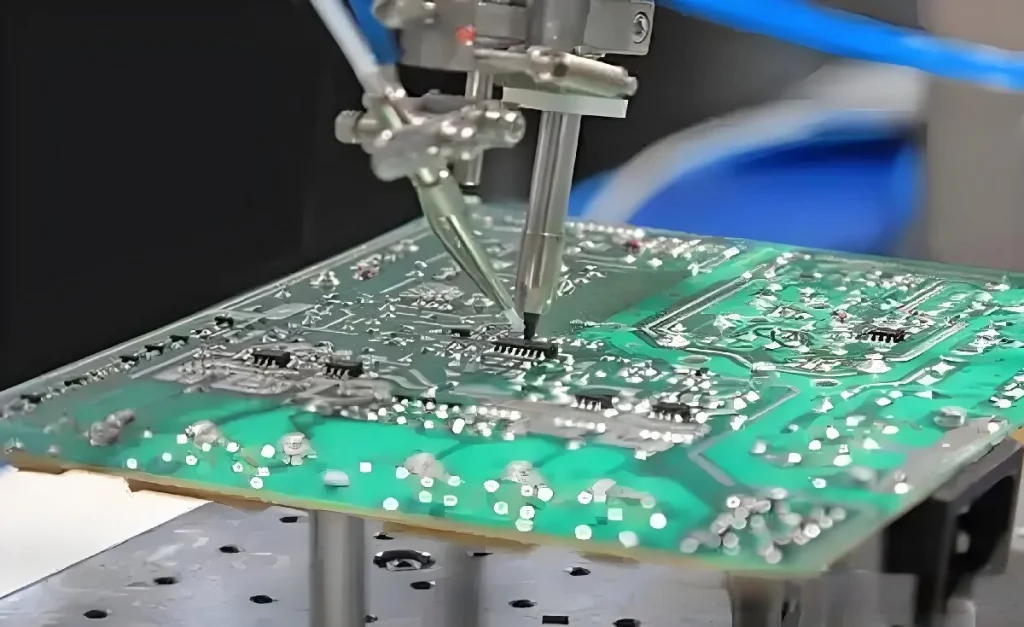

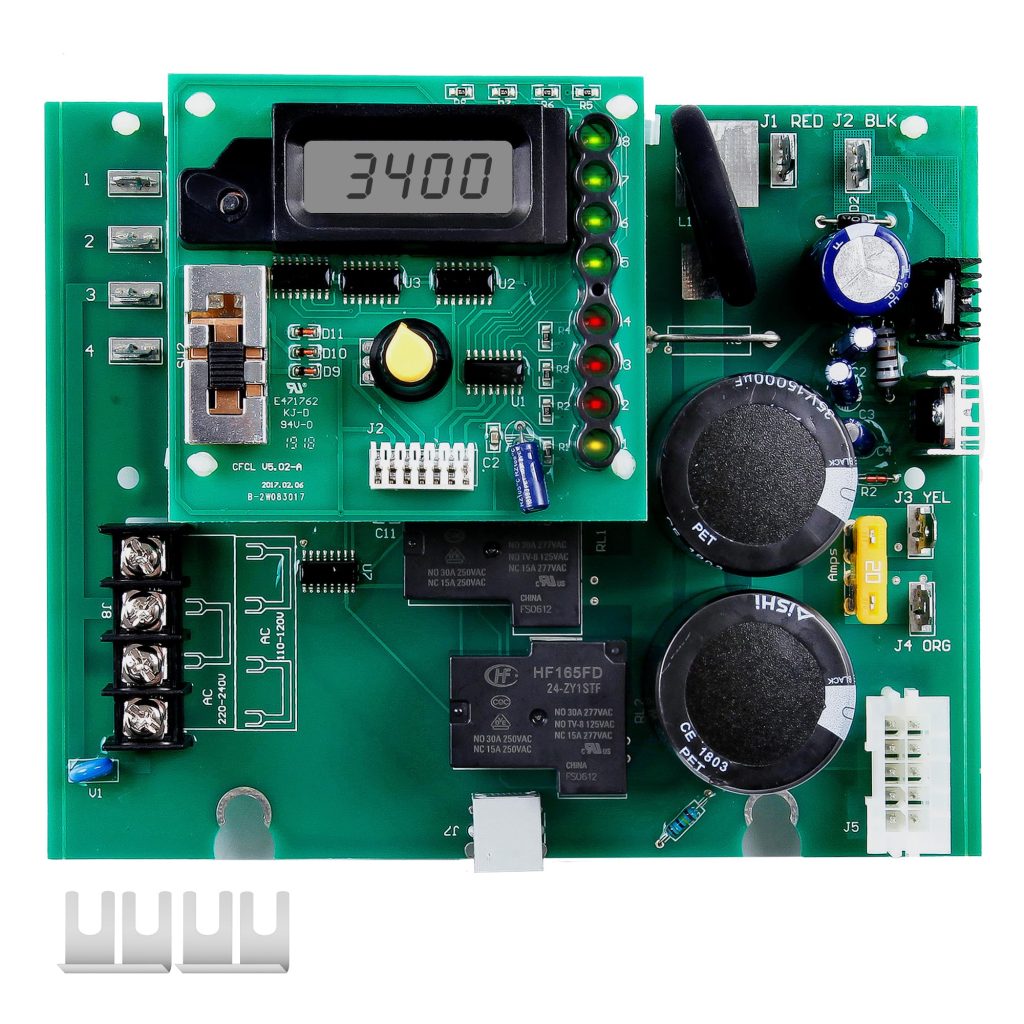

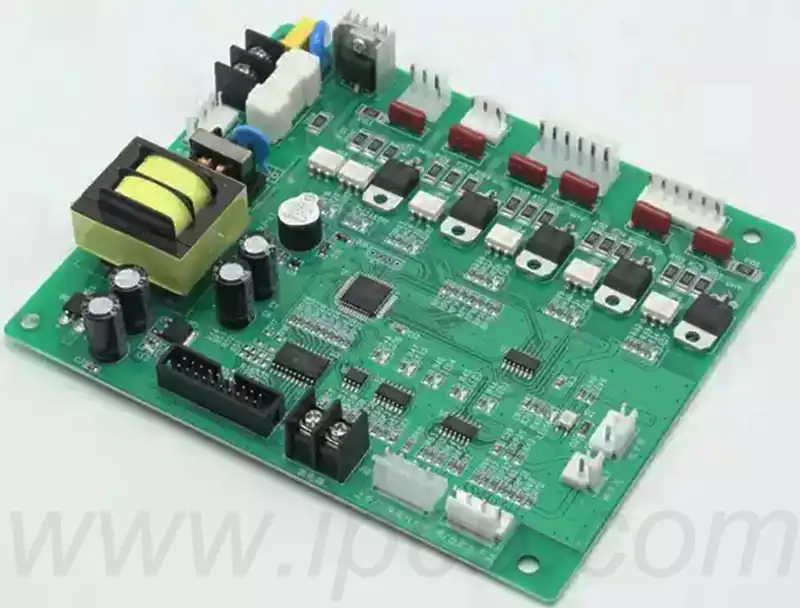

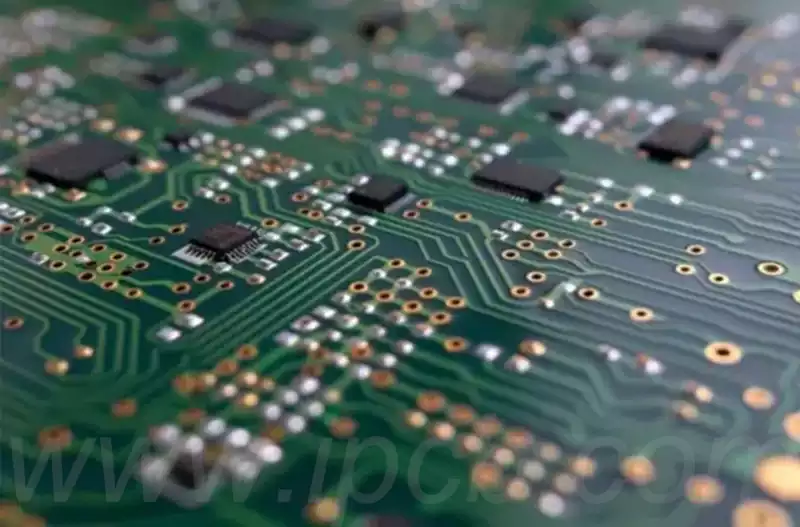

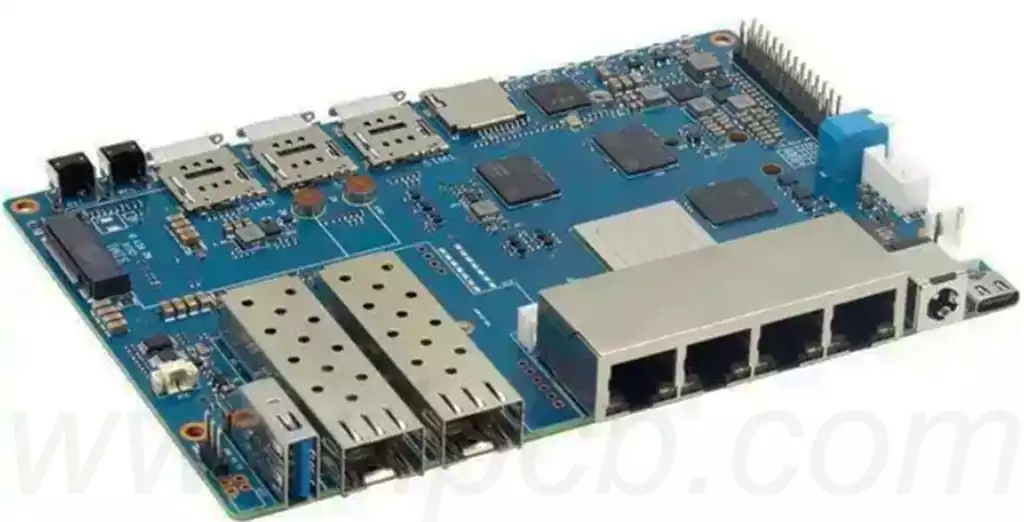

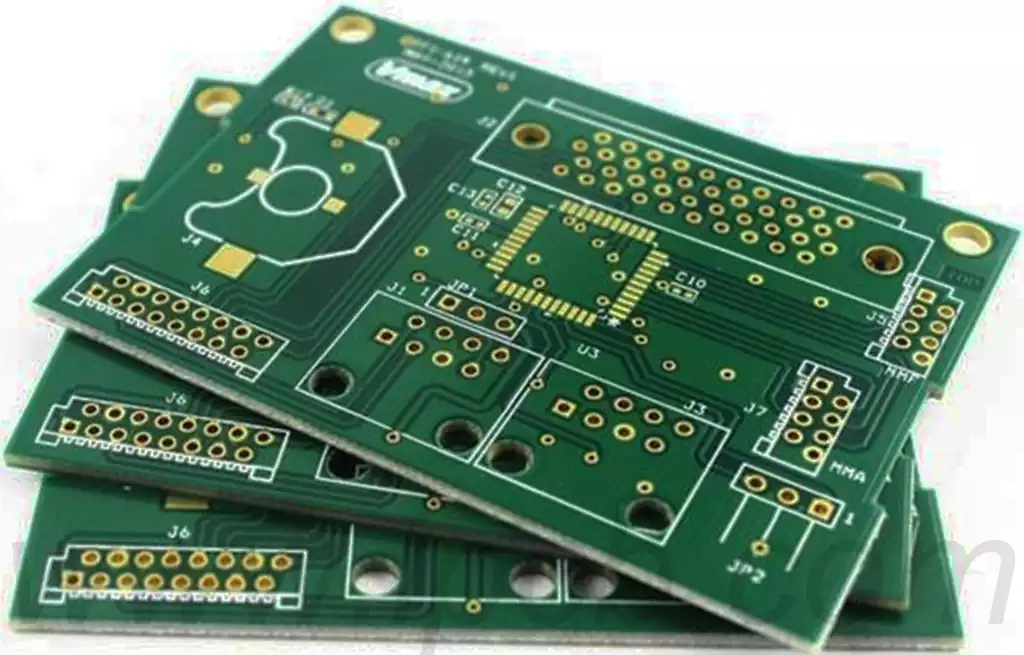

PCB Copper Layup is the process of filling areas of a PCB board that are not wired or unused spaces with solid copper skins. Copper plays multiple key roles in PCB design including, but not limited to, reducing ground impedance, enhancing interference immunity, connecting to ground to reduce loop area, and promoting heat dissipation. Copper […]