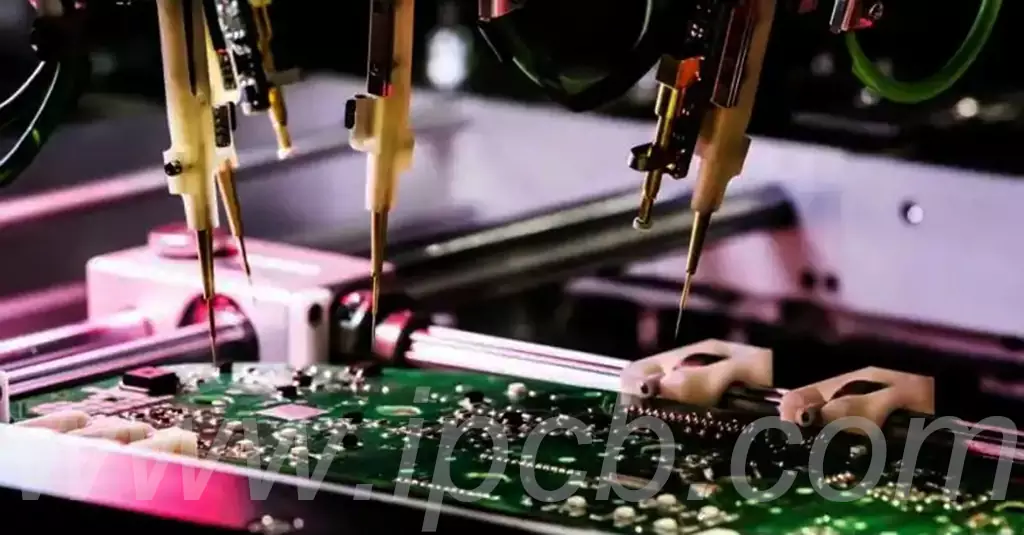

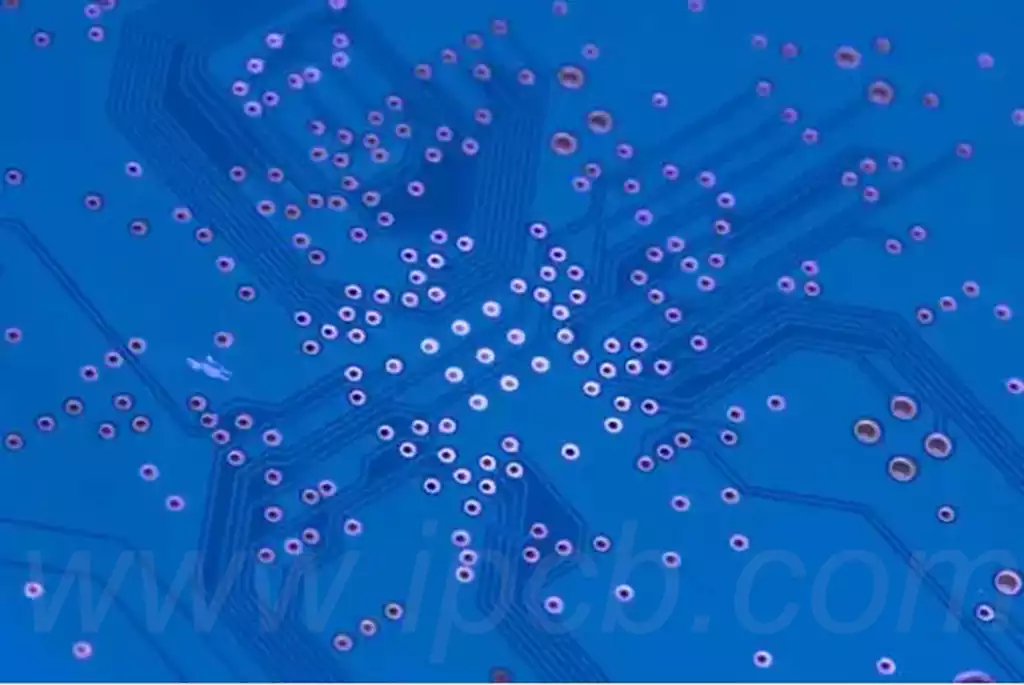

Remove solder from pcb to quality assurance

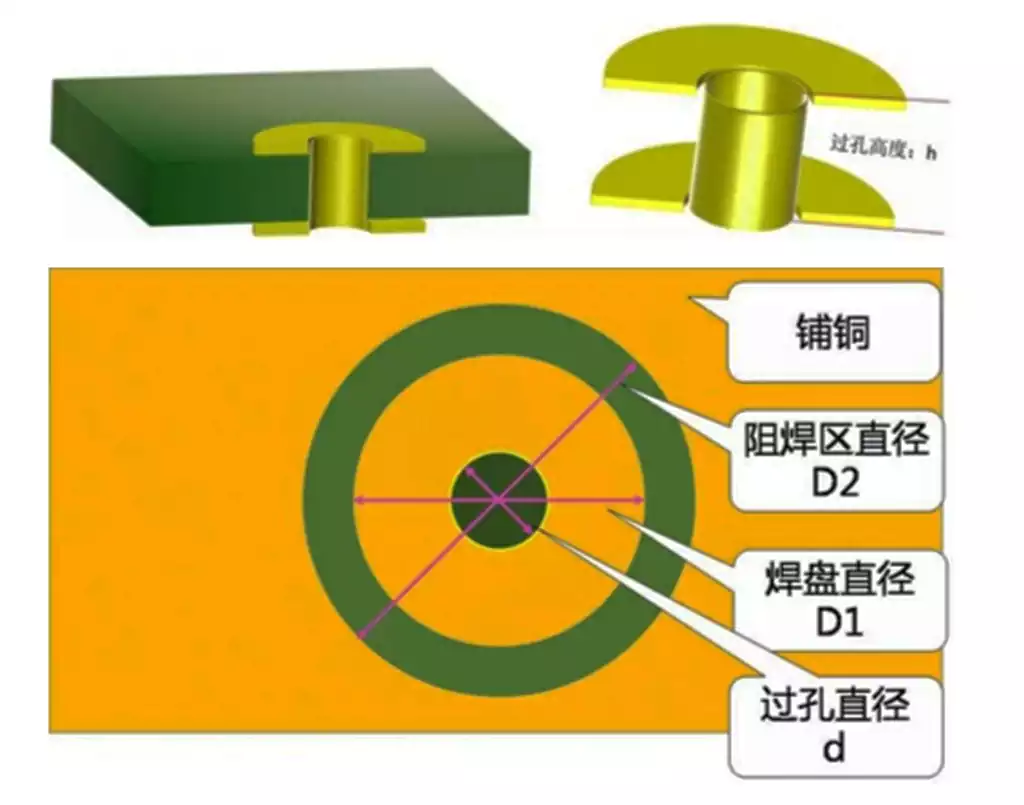

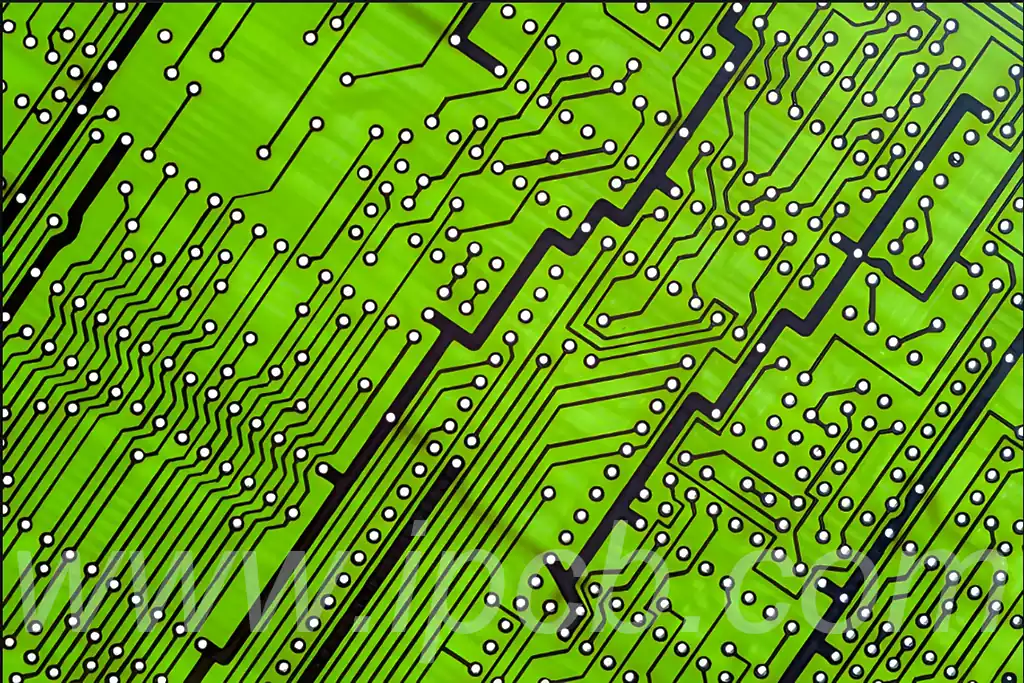

Solder flux residue is generally defined as the residual material left on the surface of a circuit board or other workpiece during a soldering operation or electronics manufacturing process due to the use of soldering materials (e.g., solder or solders), through-hole soldering, and by-products generated during the soldering process. These residual components may include solder […]