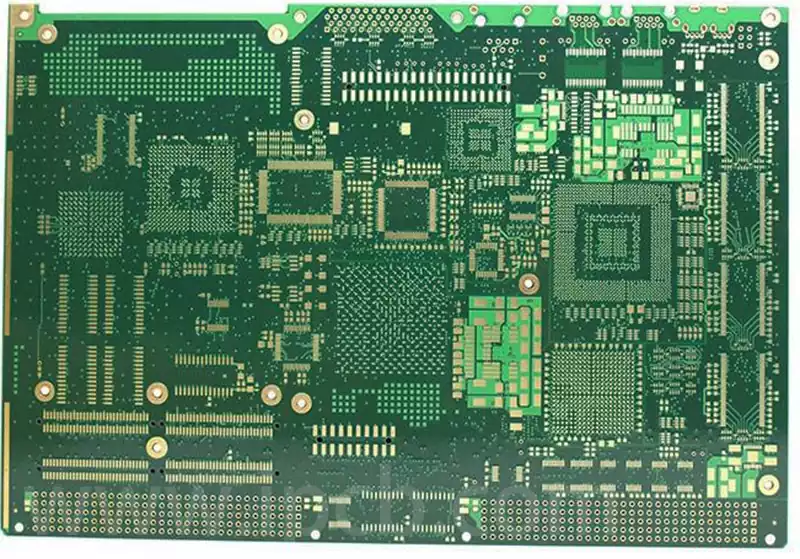

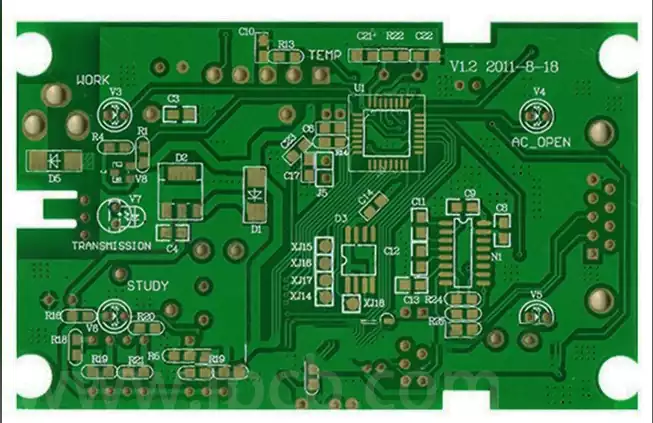

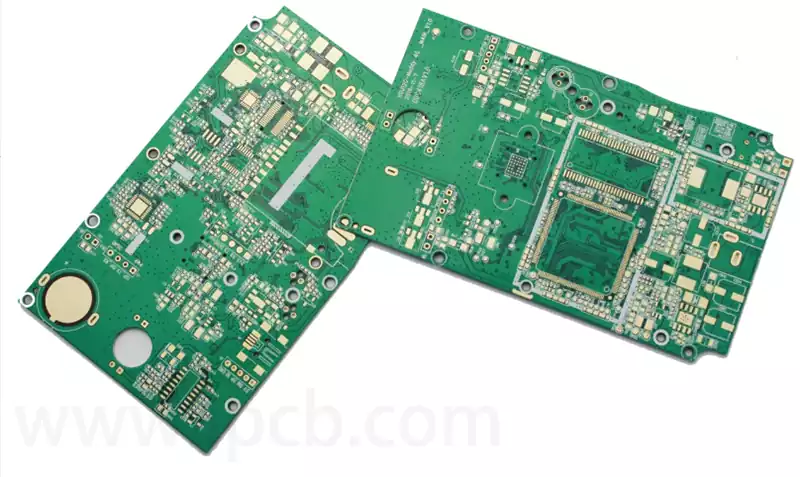

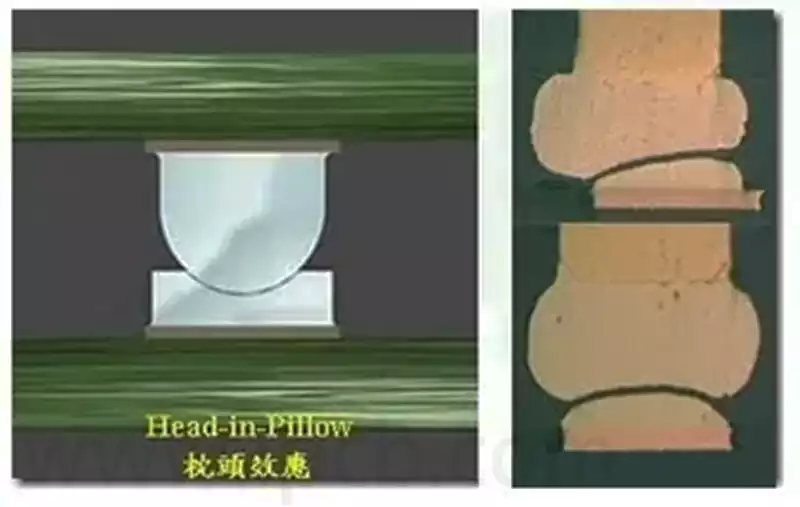

Common Defects in Printed Circuit Boards

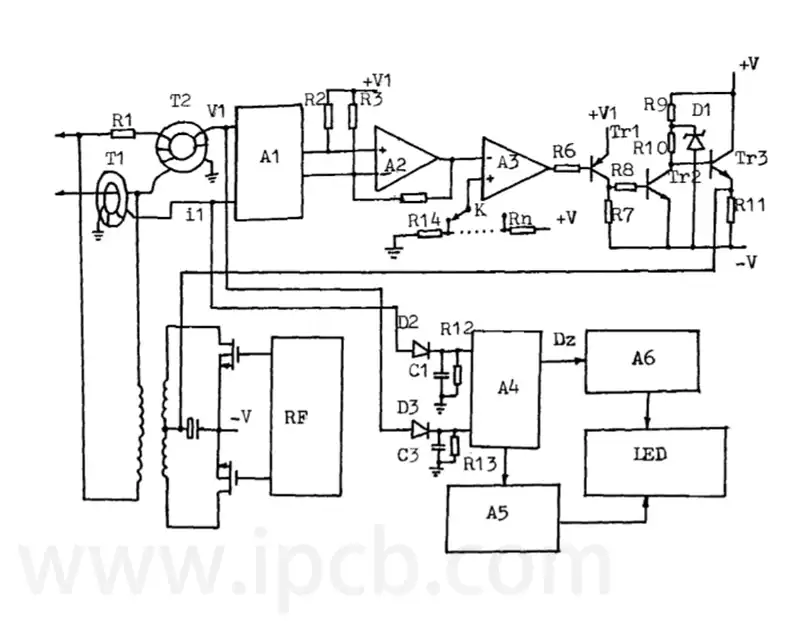

Printed circuit board (PCB) as a core component of modern electronic equipment, its quality and reliability of the performance of the entire electronic system plays a vital role. However, during the manufacturing, storage and use of PCBs, they are affected by various factors such as temperature, humidity, contaminants and process operations, and often suffer from […]