The Fundamental Differences and Design Significance of FFC and FPC Cables

In modern electronic products, flexible interconnect technology is increasingly becoming a critical component. The selection and design of FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) cables directly impact product reliability, performance, and assembly efficiency. Many people easily confuse the two, but in fact, the differences are significant in terms of structure, application scenarios, and manufacturing processes. Understanding these differences helps engineers make optimal decisions during the system design phase and provides clear guidance for procurement and production.

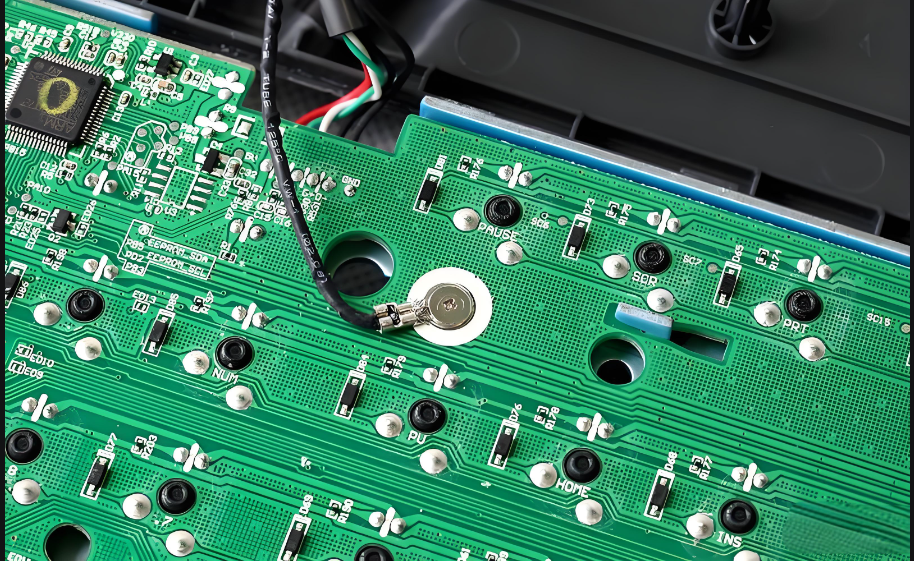

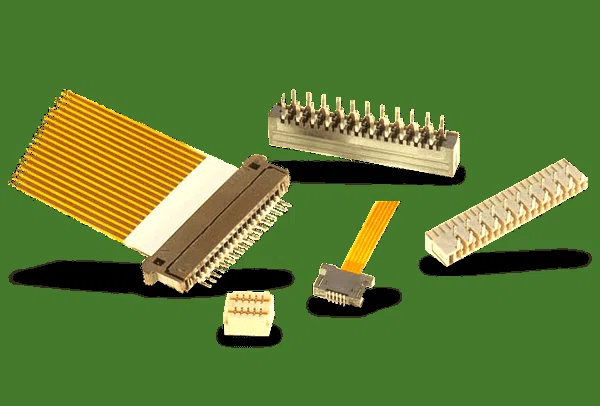

FFC cables typically consist of parallel-aligned metal conductors and an insulating film, emphasizing standardization, low cost, ease of mass production, and rapid replacement. Its typical application is short-distance connections between motherboards and modules, such as laptop displays, printer internal modules, or simple control board interconnections. Due to its regular conductor arrangement and fixed line spacing, FFC offers predictable layout and relatively lower design difficulty. However, in complex, curved, and space-constrained environments, its performance may be limited by mechanical fatigue and signal integrity requirements.

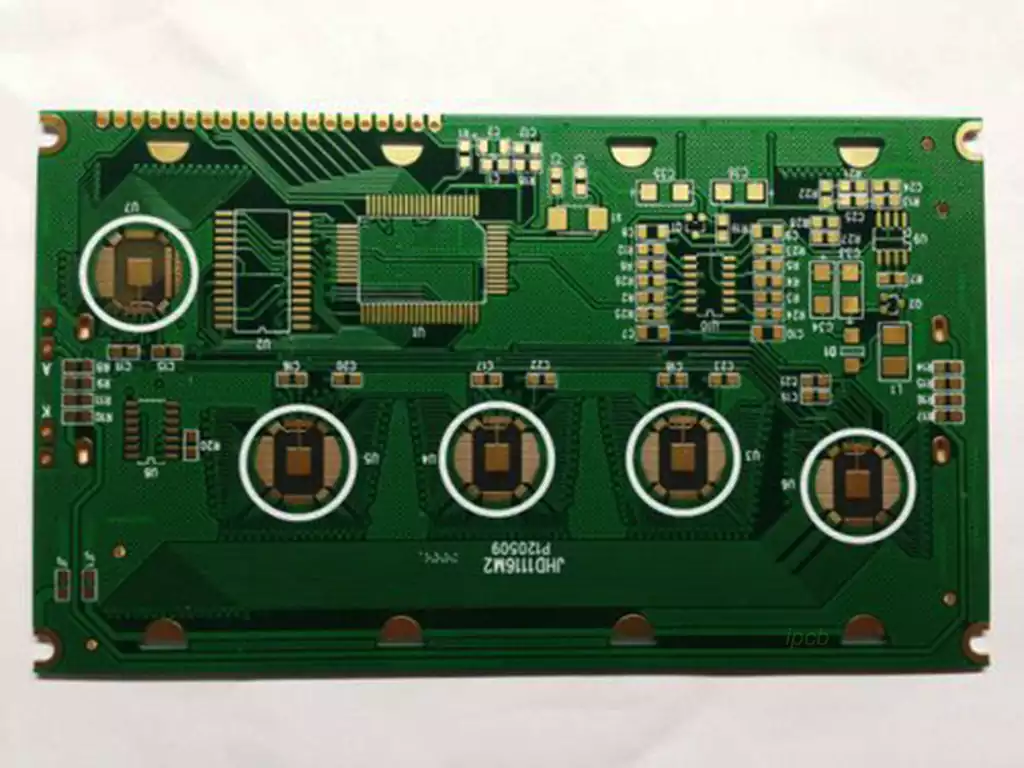

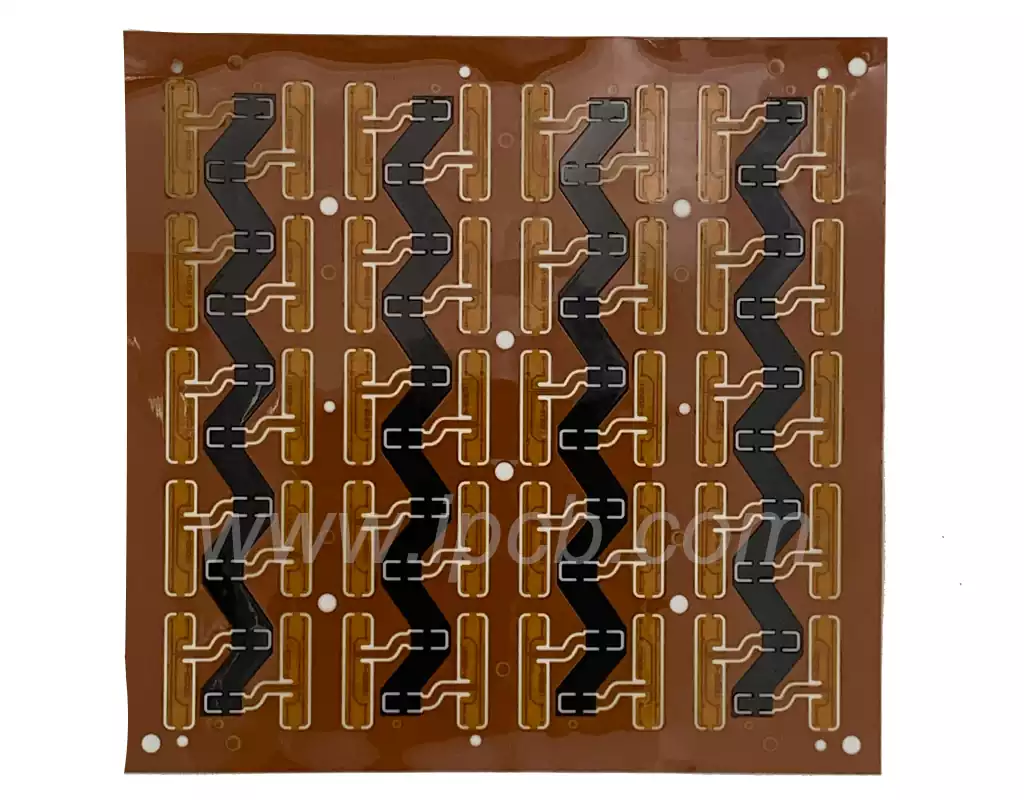

In contrast, FPC cables are essentially customizable flexible printed circuits, whose conductor layout, impedance control, number of layers, and shape can all be optimized according to application requirements. FPCs can adapt to complex spatial folds, curved traces, and multi-layer interconnects, and can ensure signal integrity and power stability in high-speed, high-frequency signal environments. Therefore, FPCs are an irreplaceable flexible interconnect solution in high-end consumer electronics, medical devices, aerospace, and high-speed communications.

From a manufacturing process perspective, FFC production is simpler, typically completed through lamination and punching processes, resulting in a short production cycle and low unit price, suitable for standardized, high-volume demands. FPCs, on the other hand, require multiple processes such as flexible PCB design, copper plating, etching, and lamination, leading to a longer production cycle, but enabling a high degree of customization in function and shape. This difference creates a clear trade-off between cost and performance.

Furthermore, FFCs and FPCs also differ in their reliability performance. Due to limitations in materials and structure, FFC (Flexible Connected Cable) has limitations in bending life, temperature resistance, and long-term reliability. FPC (Flexible Printed Cable), on the other hand, can significantly improve bending life and high-temperature adaptability through material selection, linewidth optimization, and interlayer structure design. This is why high-end electronic products generally choose FPC, while entry-level or standardized products still tend to use FFC.

Therefore, discussing the essence of FFC vs. FPC cables is not just comparing the shape and cost of the two flexible cables, but understanding their strategic significance in system design, manufacturing processes, and application requirements. Only after clarifying the application scenario, performance requirements, and production conditions can a scientific choice be made, and the correctness of this choice directly affects the reliability of the entire electronic system and the user experience.

Comparison of Signal Performance and Application Scenarios between FFC and FPC

In electronic systems, signal performance is one of the core indicators for evaluating the quality of flexible interconnect cables, and FFC and FPC differ significantly in this regard. Due to its simple structure, FFC conductors are usually arranged in a single layer in parallel, and the signal line spacing is fixed. Therefore, it performs stably in low-speed signal transmission, standard voltage, and low-frequency environments, meeting the interconnection needs of most common modules. However, as signal rates increase and operating frequencies reach tens or even hundreds of megahertzes, the parasitic capacitance and inductance effects of FFCs become apparent, limiting signal integrity and leading to crosstalk, reflections, or amplitude attenuation.

In contrast, FPCs can be customized in terms of conductor width, spacing, and number of layers for specific applications, enabling precise optimization of differential signals, impedance control, and high-speed signal paths. For example, in high-speed communication equipment or high-speed data acquisition modules, FPCs can significantly reduce signal distortion and crosstalk through differential pair wiring and impedance control, ensuring reliable data transmission. This is a key reason for the widespread use of FPCs in high-speed, precision electronic products.

From an application perspective, FFCs are more suitable for environments with relatively regular spaces and lower signal requirements, such as laptop display connections, printer internal motor control, and interconnection of general consumer electronics modules. Their advantages lie in standardized production, easy installation, and low cost. FPCs, on the other hand, are suitable for high-performance applications with complex shapes, limited space, and the need for bending or folding, such as foldable smartphone screens, internal interconnection of medical imaging equipment, connection between drone control boards and sensor modules, and flexible wiring for high-speed interfaces in high-speed communication or data processing systems. Furthermore, regarding reliability, while FFC has a simple structure, it is prone to conductor breakage or insulation aging under long-term bending, high temperature, or vibration environments. FPC, on the other hand, through optimized material selection and interlayer structure design, can achieve tens of thousands of bending cycles, high-temperature resistance, and vibration resistance, ensuring long-term stable operation in complex environments. Therefore, in scenarios with stringent reliability requirements, FPC is significantly superior to FFC.

In conclusion, the choice between FFC and FPC is not simply based on cost or shape, but rather on the specific system’s signal performance requirements, space constraints, and long-term reliability goals. Understanding the differences in performance and application scenarios can avoid repeated modifications and system debugging risks in the early stages of design, providing reliable assurance throughout the entire product development process.

Key Considerations in the Design and Manufacturing Process of FFC and FPC

In the practical application of flexible interconnect cables, the design and manufacturing stages often determine the final system’s reliability and performance. Whether it’s FFC or FPC, every wiring decision and every process step can have a profound impact on signal integrity, mechanical life, and overall system stability. Understanding these key considerations is essential for ensuring the long-term stable operation of electronic products in complex environments.

First, the bending characteristics and spatial constraints of the cable must be considered during the design phase. Due to its single-layer parallel conductor structure, FFC typically can only withstand a limited number of bends. Ignoring the bending radius or folding direction in product design can easily lead to conductor fatigue or even breakage. In contrast, FPC allows for multi-layer designs and complex routing. By optimizing conductor thickness, material flexibility, and interlayer structure, it can withstand tens of thousands of bends without damage. Therefore, the cable’s range of motion and operating environment must be clearly defined during the design phase, and materials and layer structures must be selected accordingly.

Second, signal integrity and impedance control are core issues in high-speed or sensitive signal design. FFC has a fixed conductor spacing, limiting impedance adjustment space. If used for high-speed differential signals or long-distance transmission, it is prone to crosstalk, signal attenuation, and reflection. FPC, on the other hand, can control impedance and reduce signal distortion by customizing differential pair width, spacing, and multiple shielding layers. During the design phase, engineers need to evaluate signal types, frequencies, and rates to ensure that the wiring scheme meets electrical performance requirements, not just mechanical connection needs. Furthermore, soldering and connection processes are often overlooked. FFC typically uses ZIF or non-ZIF sockets for direct crimping, which is convenient for installation but sensitive to insertion force and soldering temperature; slight errors can lead to poor contact or interface failure. FPC, on the other hand, may use pad soldering, COB (Chip on Board), or FFC sockets. Each process requires precise adjustments based on material thickness, copper foil thickness, and copper coverage area. Ignoring process parameters often leads to batch inconsistencies, affecting yield and reliability.

In addition, environmental factors are equally important in the design and manufacturing stages. FFC and FPC exhibit significant differences in performance under high temperature, humidity, or vibration conditions. During the design phase, appropriate materials, such as high-temperature polyimide or moisture-resistant films, should be selected based on the final product’s operating environment. Appropriate curing, baking, and stress relief treatments should be employed during the manufacturing process to ensure the cable does not fail during long-term use.

Finally, testing and verification strategies are also crucial. In flexible cable design, premature or insufficient testing may mask potential problems. After the design is completed, mechanical bending tests, environmental aging tests, and high-speed signal transmission tests should be conducted to verify the feasibility and reliability of the design through real data. Scientific verification not only identifies design deficiencies but also provides crucial data for mass production.

In short, every decision in the design and manufacturing stages, whether using FFC or FPC, is critical. From bending performance to signal integrity, from soldering processes to environmental adaptability, every aspect affects the stability and lifespan of the final product. Only by fully understanding these key considerations can scientific choices be made in actual projects, maximizing the advantages of flexible interconnect technology in products.

Case Studies and Risk Summary of FFC and FPC in Practical Applications

In the development of electronic products, there is often a gap between theoretical design and practical application, which is particularly evident in the selection and wiring of FFC and FPC cables. Analyzing typical projects provides a clear understanding of the differences in performance, reliability, and production efficiency between the two, while also helping engineers and managers avoid repeating erroneous decisions.

A typical example is the connection between a laptop screen and the motherboard. Most standard laptops use FFC for screen signal transmission due to its short distance, high standardization, and low production cost. The main problems encountered in the project included conductor breakage due to excessive bending, poor socket contact, and signal attenuation. Analysis revealed that these issues largely stemmed from insufficient consideration of bending radius and socket mounting positions during the product design phase. The solutions involved optimizing wiring paths, adding mechanical supports, and strictly controlling bending angles and the number of bends. This case clearly illustrates that while FFC (Flexible Printed Circuit) is low-cost, mechanical stress management and reliability design must be planned in advance; otherwise, it can easily lead to repairs and rework later.

Another type of case involves the internal interconnects of high-end smartphones, especially foldable screen designs. These projects typically use FPC (Flexible Printed Circuit). FPC allows for multi-layer designs, impedance control, and complex folds, adapting to space constraints and high-speed signal requirements. However, problems such as FPC damage, signal crosstalk, and unstable manufacturing yields still occurred in the project. In-depth analysis revealed that the root cause was a mismatch between FPC design and manufacturing process: conductor thickness, interlayer spacing, and bending direction did not adequately consider actual assembly conditions. Ultimately, by adjusting the interlayer structure, optimizing differential routing, and strictly controlling the manufacturing process, a solution was achieved that satisfied both signal integrity and ensured folding lifespan. This case emphasizes that even with high-end FPCs, reliability risks can still arise if the design and manufacturing process are not properly integrated.

FPCs are also widely used in industrial equipment and medical instruments. In one medical imaging device, FPCs were used to connect high-speed sensors and the main control board. These signals were high-frequency and extremely sensitive to noise. Initially, FFC was used as a replacement, but this resulted in severe signal attenuation, frequent noise interference, and unsatisfactory system performance. Ultimately, FPCs were adopted, and during the design phase, differential pair routing was controlled, shielding layers were added, and vias and bending areas were optimized, achieving stable signal transmission. This case clearly demonstrates that for scenarios with high performance and reliability requirements, choosing FPCs is not only a technical requirement but also a prerequisite for system feasibility.

Several key lessons can be learned from these cases: First, FFCs are suitable for short-distance, low-speed, standardized interconnections; second, FPCs are suitable for spatially complex, high-speed, and high-reliability applications; third, any cable design must comprehensively consider the product’s operating environment, bending requirements, and signal performance; fourth, close collaboration between design and manufacturing is essential, and testing and verification are indispensable. Ignoring these lessons can easily lead to signal anomalies, mechanical failures, or decreased production yields later on.

In conclusion, the practical application of FFC and FPC is not merely a matter of material and structural selection, but also a reflection of system design capabilities and engineering experience. Case studies demonstrate that theoretical choices divorced from practical application conditions can lead to risks. Only through scientific evaluation, meticulous design, and rigorous process control can the advantages of flexible interconnect technology be fully realized, safeguarding the performance and reliability of electronic products.

The Strategic Significance of FFC vs. FPC Cable Selection

Reviewing the entire article, from the structural differences between FFC and FPC, signal performance, design and manufacturing considerations, to practical application case studies, we can draw a core conclusion: choosing between FFC and FPC is not merely a matter of materials or cost, but directly relates to the performance, reliability, and long-term stability of electronic systems.

FFC, due to its simple structure, high standardization, and low cost, is suitable for short-distance, low-speed, standardized interconnect scenarios, such as laptop display connections and printer internal modules; while FPC, through flexible layer design, impedance control, and spatial folding capabilities, meets the needs of high-speed, high-density, and high-reliability applications, such as foldable screen phones, medical imaging equipment, and drone control modules.

Thorough consideration of bending radius, signal integrity, via optimization, and soldering processes during the design phase, along with strict adherence to material, process, and testing standards during manufacturing, are crucial for preventing later failures and improving yield. Practice has proven that scientific selection and meticulous design can maximize the advantages of flexible interconnects, achieving dual guarantees of system performance and reliability.