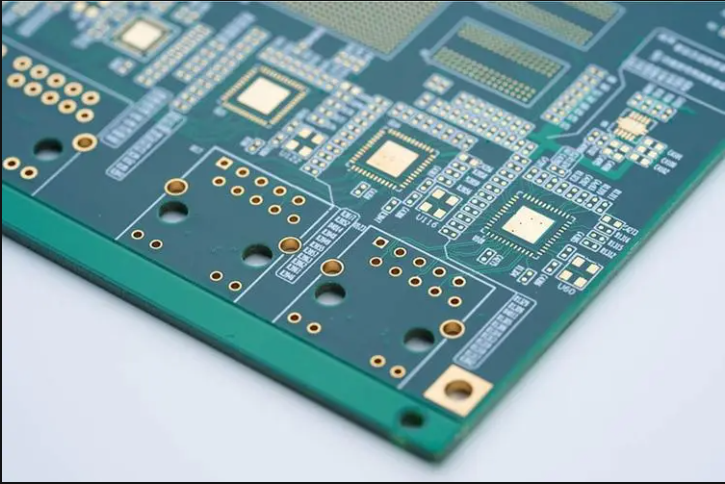

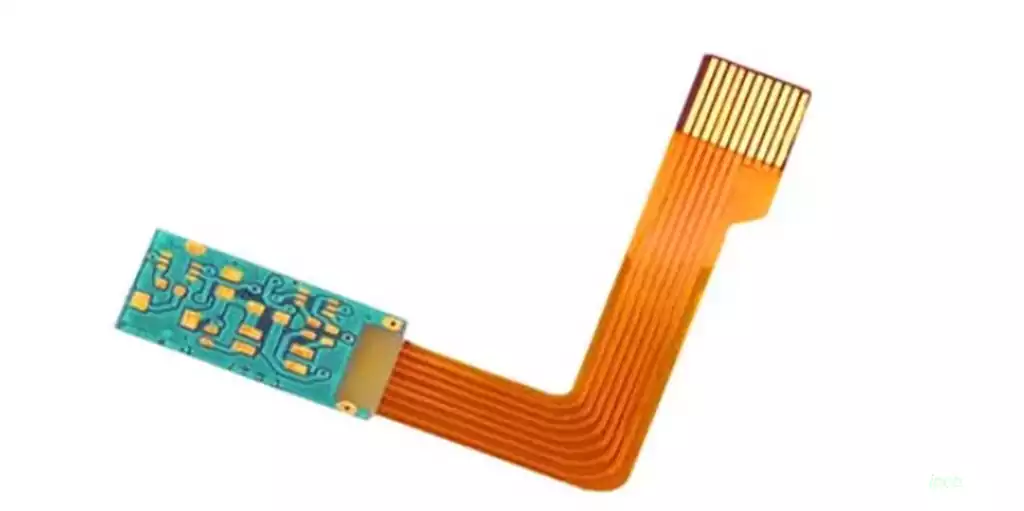

Circuit board glue is a specialized adhesive used in the manufacture of circuit boards. Its main function is to fix the electronic components on the circuit board to ensure the stability and reliability of the circuit. Compared with traditional soldering methods, circuit board glue has better insulating properties and higher temperature resistance, which can effectively prevent electronic components from falling off or being damaged due to temperature changes or mechanical vibration during the working process.

Various types of adhesives are commonly used in the PCB substrate manufacturing process, and these different types of adhesives offer unique properties and advantages for a variety of applications in the electronics industry. Proper use ensures the safe operation, heat dissipation, insulation and protection of electronic equipment in a variety of demanding conditions.

Hot Melt Adhesives

Hot melt adhesives, as a special solid adhesive material, can melt quickly at a specific temperature and cure at room temperature for efficient thermal bonding. Its fast bonding and high strength characteristics make it especially widely used in the electronic field, mainly used for solid fixing of electronic components, tight bonding of circuits and connection of other electronic parts.

Thermally Conductive Silicone

Thermally conductive silicone, also known as thermally conductive paste or thermally conductive adhesive, is a silicone material with both high thermal conductivity and excellent insulating properties. It maintains its soft grease form over a wide temperature range (-50°C to +250°C). With excellent electrical insulation and thermal conductivity, thermally conductive silicone plays a key role in the internal heat dissipation of electronic products, and is mainly used to connect power tubes and other heat generating components with heat sinks, increasing the contact area and realizing the effective conduction and dissipation of heat.

Yellow Gum

Yellow glue, as a water-based self-adhesive gel adhesive with a pungent odor, is known for its excellent insulating, moisture-proof, shock-proof and thermal conductivity properties. It ensures stable operation of electronic components even in harsh environments. The curing speed of yellow adhesive is affected by various factors such as ambient temperature, humidity and wind speed, etc. When yellow adhesive-coated parts are placed in the air, a skin will gradually form. Therefore, the operation process needs to ensure timely completion to avoid excessive surface crusting. It is mainly used in electronic products for the fixing, encapsulation, protection and insulation of inductors, coils, transformers and other components.

As an important material in the field of electronic manufacturing, circuit board adhesive plays an irreplaceable role. With the continuous progress of technology and environmental awareness, its performance and environmental protection will be further improved to provide strong support for the development of electronic manufacturing.

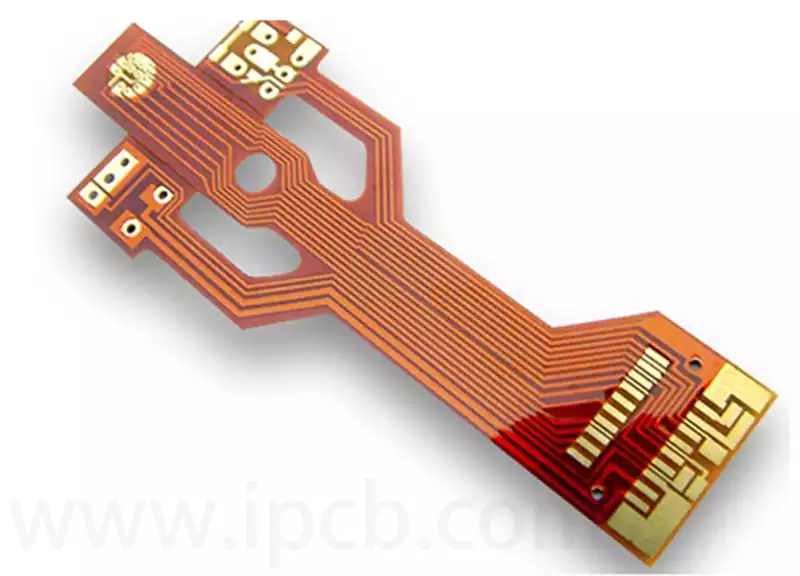

Red Adhesive

Red glue, a kind of polyolefin adhesive easy to heat curing, when the temperature rises to 150 ° C, the red glue is from the paste into a solid state. Chip components can be easily fixed to circuit boards by dispensing or printing. Subsequently, the adhesive is cured by heating in an oven or by reflow soldering. In the case of double-sided board mounting, the adhesive prevents small back-side components from falling off during the wave soldering process. Advantages of red adhesive include consistent bond strength, appropriate viscosity and rheological properties for stencil printing, consistent adhesive volume that is less likely to overflow or edge too much, high stability for preservation, and prevention of deflection when placing components at high speeds. It is mainly used for fixing chip components on circuit boards.

Silicon Adhesive

Silicone adhesive is a liquid material that is soluble in water and cures to a solid form similar to an adhesive after drying. It is widely used in glassworking and sealing applications. In the field of electronics, silicone adhesives are mainly used for potting, insulation and flame retardancy of electronic modules, sensors, etc., as well as bonding and fixing of electronic components to ensure the stability and safety of electronic products.

As an important material in the field of electronic manufacturing, circuit board glue plays an irreplaceable role.With the continuous progress of technology and environmental awareness, its performance and environmental protection will be further enhanced to provide strong support for the development of electronic manufacturing.