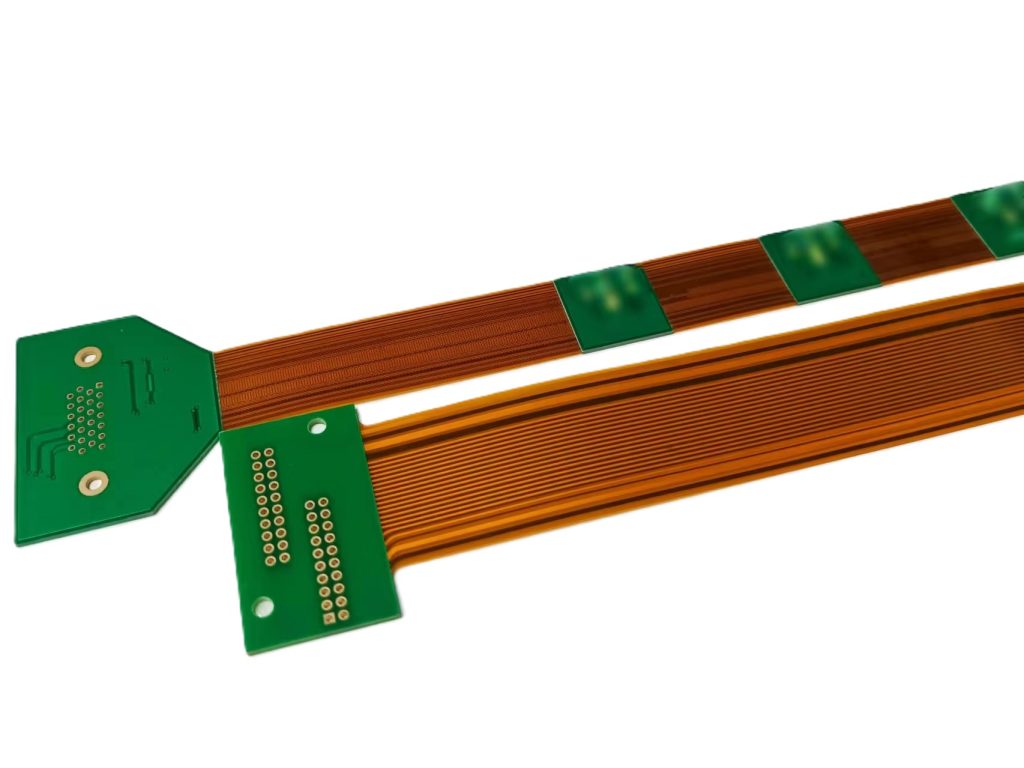

What is a circuit board stiffener?

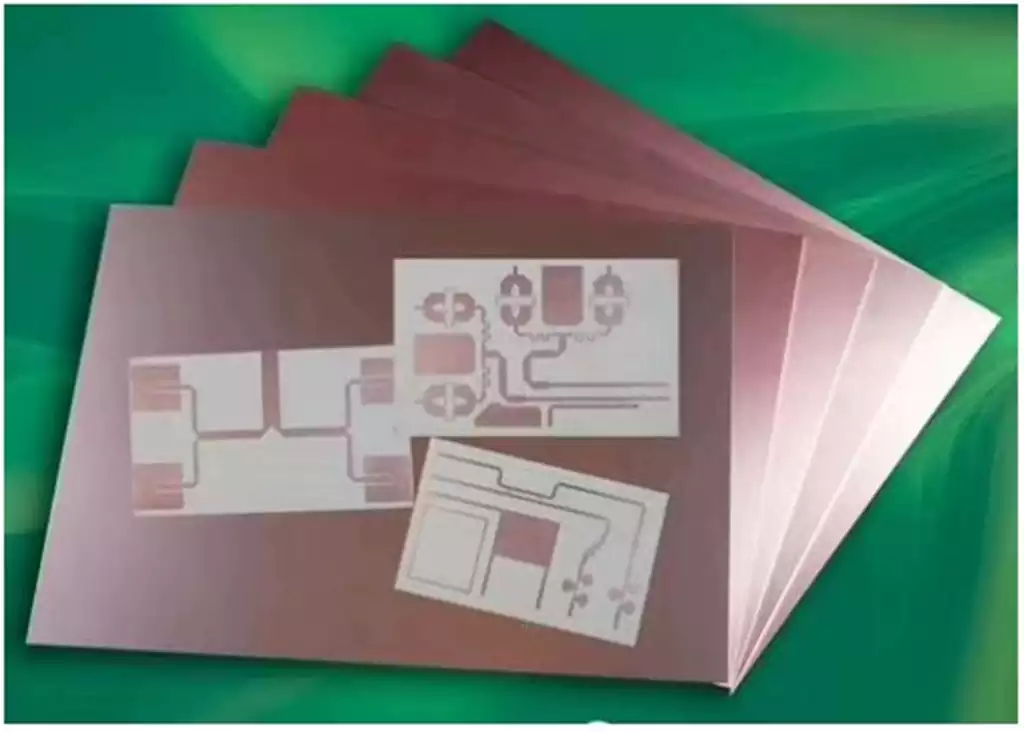

In the field of printed circuit boards, a circuit board stiffener is a support material that is glued to a specific part of the PCB to make it stiff (or thicker). Note that circuit board stiffener is not initially part of the circuit board, but is an additional component introduced at the final stage of the manufacturing process.

Why use circuit board stiffeners?

- To meet thickness requirements

Flexible circuits and rigid circuit boards are often required to have a certain thickness in order to fulfill the assembly requirements. Often, this is to complete the installation in a specific area to ensure a consistent thickness, which may be necessary to maintain repeatability and common components (such as the length of mounting screws on the board). However, with flexible circuits, they tend to be relatively very thin in order to maintain flexibility, which makes operations such as mounting to an enclosure difficult. To solve this problem, circuit board stiffeners can be added to increase the thicker portion of the circuit without sacrificing flexibility.

Another common reason for the need for circuit board stiffeners is to meet the thickness requirements of Zero Insertion Force (ZIF) connectors. These connectors require a strict thickness to ensure that the components are properly clamped to the board. Whenever a ZIF connector is used, the polyimide circuit board stiffener will compensate for the difference in thickness that the board cannot reach to meet the ZIF thickness requirements. - Creating a Stable and Flat Area

While the flexibility of the board is an advantage, it can also present significant disadvantages. For example, if flexible circuits are to be mounted and hung, any component will sag considerably. With the use of circuit board stiffeners, the sag is greatly reduced, allowing the circuit board to hang freely. This is a very niche situation, but for more specific situations, it allows the flex circuit to prevent surface mount components and other items from coming into contact with each other if the circuit board is bent. By placing circuit board stiffeners on the board, the area is forced to remain flat, which creates stability and greatly reduces points of failure. - Better Handling

This is almost entirely straightforward. Handling flexible circuits can be difficult. From manufacturing and assembly to installation and everyday use, flexible circuits can easily rip or tear. By adding circuit board stiffeners, circuit boards can be easier to handle and prevent mishandling accidents that could damage or destroy the board. The thinner a circuit board is, the more likely it is to be damaged, making circuit board stiffeners even more important when the thickness is small. - Supporting Plated Areas

Typically, most flexible circuits only use a type of plating called ‘pad plating’, where only the through-holes and vias are plated along with the pads on either side. While this is an effective plating method for flexible circuits, it can cause intermittent open circuits if these holes are located in a bend area. This is because copper plating is not suitable for bending, and the grain orientation of the copper may make it more brittle than the rolled annealed copper typical of the flex area. Therefore, the use of circuit board stiffeners in these areas to support the plated holes prevents the area from bending, thus preventing the hole plating from breaking down during bending and thus preventing the creation of intermittent open circuits or even complete open circuits. - Support component areas

Per IPC-2223, for flexible circuits, it is recommended that reinforcing bars be installed to support the component at the location and area where the component is placed. There are two reasons for doing this. The first reason is that the circuit board stiffener is needed due to the fact that, as described in the previous section, there are sometimes plated holes in the area where the component is placed. The second reason is that the components are adhered using solder joints. While these solder joints are effective at holding components in place, if they flex, they can tear copper from the board, break copper, or break solder joints, which can damage the board and render it unusable.

How to apply PCB circuit board stiffeners?

Make sure that when you attach the PCB stiffener to the plated-through-hole component, the stiffener is on the same side of the board where you insert the component so that you have access to the pads. You can attach circuit board stiffeners to both sides of the part, but the assembly requires a review of the array configuration to ensure that you don’t encounter any complications during assembly. Typically, you will use heat and pressure to attach circuit board stiffeners to the circuit via thermal bonding. You can also use pressure-sensitive adhesives to attach PCB circuit board stiffeners.

When designing flex circuit PCBs, circuit board stiffeners are a reliable and often necessary option to improve the durability and reliability of flex circuits when assembling various flex circuit designs. While you may feel that PCB circuit board stiffeners complicate printed circuit board design, they allow your flex circuit board to function more efficiently in a wider range of applications. You have many options for combining various circuit board stiffener types in your PCB design to get the results you want.