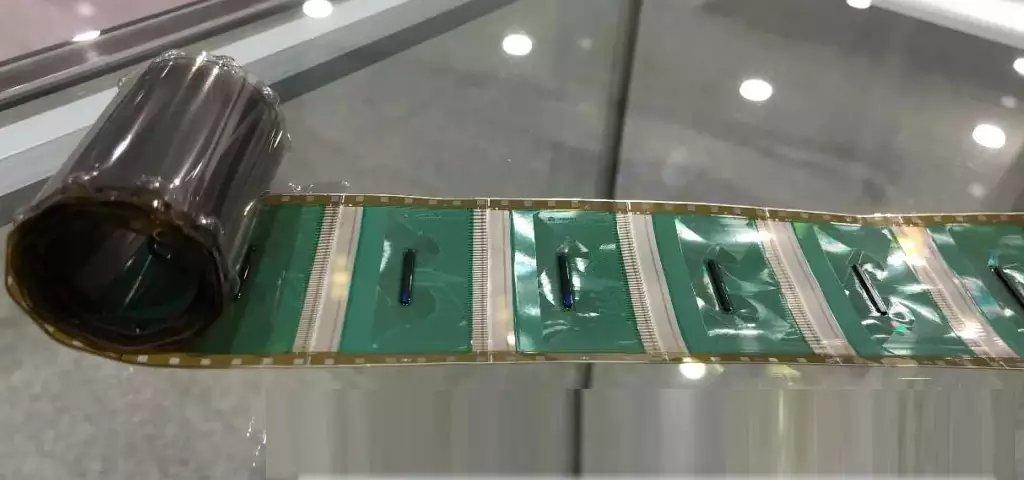

What is COF? It stands Chip On Flex, a technology that fixes integrated circuits (ICs) directly onto flexible circuit boards. It utilizes a flexible add-on circuit board as the carrier for encapsulating the chip, combining the chip with the flexible substrate circuitry to achieve a seamless connection between the chip and the circuitry. The emergence of this technology not only greatly reduces the size of electronic products and improves the degree of integration, but also makes electronic products thinner, lighter and more flexible, providing strong technical support for the development of wearable devices, smart homes, and other emerging fields.

COF technology can be widely used in electronic products, especially in areas requiring high density, high reliability, and high flexibility. The manufacturing process of it is quite complex, requiring fine process control and strict quality inspection. With the continuous development and progress of electronic manufacturing technology, COF technology will play an increasingly important role in the future manufacturing of electronic products.

The process flow of COF die flexible film construction technology includes the following steps:

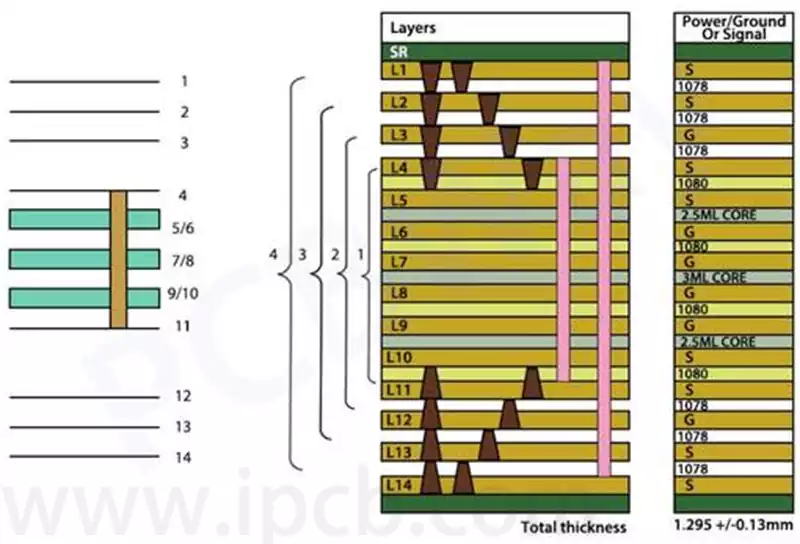

Flexible substrate fabrication: select suitable flexible materials, such as polyimide, polyester, etc., for cleaning, drying and surface treatment for subsequent metal layer deposition and circuit fabrication.

Metal layer deposition: A metal film is deposited on the flexible pcb using physical or chemical coating methods as the conductive layer of the circuit. Commonly used metal materials include copper and nickel.

Circuit production: in the metal layer using photolithography, etching, and other technologies to produce circuits, the formation of the desired circuit pattern.

Chip Mounting: The integrated circuit chip is mounted on the flexible substrate, and the connection between the chip and the circuit is generally realized by hot pressing or welding.

Filling and sealing: After chip placement is completed, epoxy resin and other materials are used to fill and seal the circuit to protect the circuit from the external environment and mechanical damage.

Inspection and testing: Inspection and testing of the made COF die flexible film assembly products, including electrical performance testing, mechanical performance testing and environmental adaptability testing, etc., to ensure that the products meet the requirements.

In the process, the following requirements need to be noted:

Precise control of process parameters: During the process of COF grain flexible film structuring technology, it is necessary to precisely control various process parameters, such as temperature, pressure, time, coating thickness, etc., to ensure the quality and stability of the product.

Selection of suitable materials: Selection of suitable flexible materials, metal materials and adhesives, etc. according to the application requirements to ensure the performance and reliability of the products.

Strict quality control: Strict quality control is carried out during the process, including quality inspection of raw materials, quality monitoring during the process and quality testing of the final product, etc., to ensure the qualification rate and stability of the product.

Advanced equipment and technology: The process of COF die soft film assembly technology requires the use of advanced equipment and technology, such as high-precision photolithography, high-precision etching machine, high-precision placement machine, etc., to ensure the accuracy and reliability of the product.

Strict environmental control: In the process, the environmental temperature, humidity, cleanliness, etc. need to be strictly controlled to ensure product quality and stability.

COF die flexible film structuring technology, as an emerging integrated circuit packaging technology, has many advantages and potential disadvantages.

Advantages:

Thinness and lightness: COF technology can fix integrated circuits directly on flexible circuit boards, and compared with traditional silicon-based packaging technology, it can realize more functions and connections in the same space, greatly reducing the size and weight of the product, and improving the integration degree and space utilization.

High density: COF technology can realize high-density line layout and smaller spacing, which improves the density of circuits and the quality of signal transmission.

High reliability: The flexible nature reduces mechanical stress and strain, improving product reliability and stability. In addition, due to its simple structure, it also reduces the possibility of failure.

High Flexibility: COF technology is suitable for substrates of various shapes and sizes, and is highly flexible and malleable, so it has a wide range of application prospects in wearable devices and other electronic products that require bending.

Low cost: COF technology has relatively low manufacturing costs and can be mass-produced, helping to reduce the overall cost of electronic products.

Potential Disadvantages:

High technical difficulty: the manufacturing process of COF technology is quite complex, requiring fine process control and strict quality inspection, with high requirements for equipment and processes.

Limited scope of application: Although COF technology has advantages in some areas, but not all electronic products are suitable for the use of this technology, some special requirements of electronic products may still need traditional packaging technology.

Material limitations: the current flexible circuit board materials are limited, may not be able to meet the needs of all electronic products, especially electronic products that require special performance.

Insufficient production capacity: the current production capacity of COF technology is relatively low, may not be able to meet the needs of mass production, so it is necessary to further improve production efficiency and stability.

The application scenarios of COF grain flexible film construction technology are very wide, mainly including the following aspects:

Flexible display panels: It can be used to manufacture flexible display panels, which can realize foldable and bendable display products, such as flexible cell phones and wearable devices, due to their thin, light, and bendable characteristics.

Sensors and Actuators: It can be used to manufacture high-density, high-reliability sensors and actuators, such as pressure sensors, accelerometers, micromotors, etc.

IC Packaging: It can be used for the packaging of integrated circuits, especially for some integrated circuits that require flexible substrates to improve integration and reliability.

Medical equipment: Flexible features make it have a wide range of application prospects in the field of medical equipment, such as wearable physiological monitoring equipment, and medical catheters.

Aerospace: It can be used in the packaging of sensors, actuators, and electronic devices in the aerospace field to improve the reliability and stability of products.

Smart home and smart building: the technology can be used in the manufacture of control panels, sensors, and actuators in smart homes and smart buildings to improve the level of intelligence in residences and buildings.

With its unique advantages and wide application prospects, COF grain soft film assembly technology is gradually becoming the core driving force for the development of future electronic products.