Ceramic substrates and PCBs play an important role in the electronics industry, each with unique material properties, manufacturing processes and application areas.

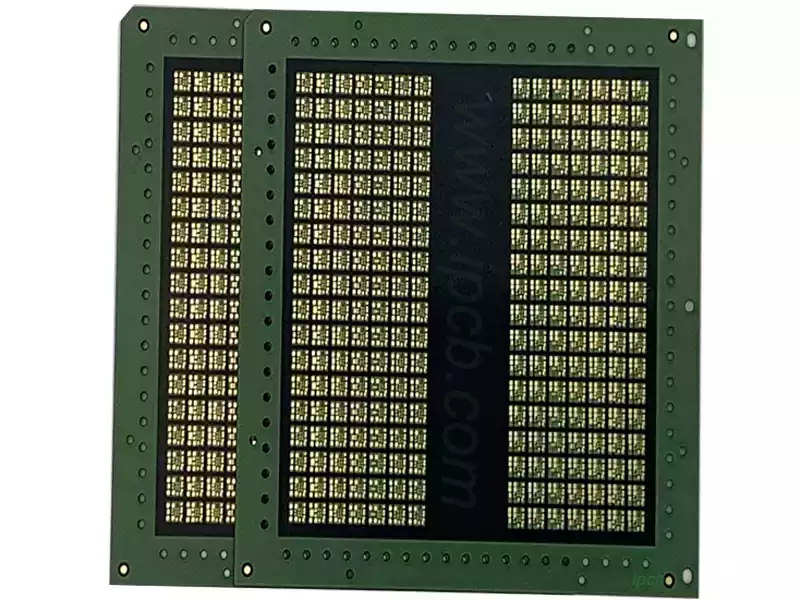

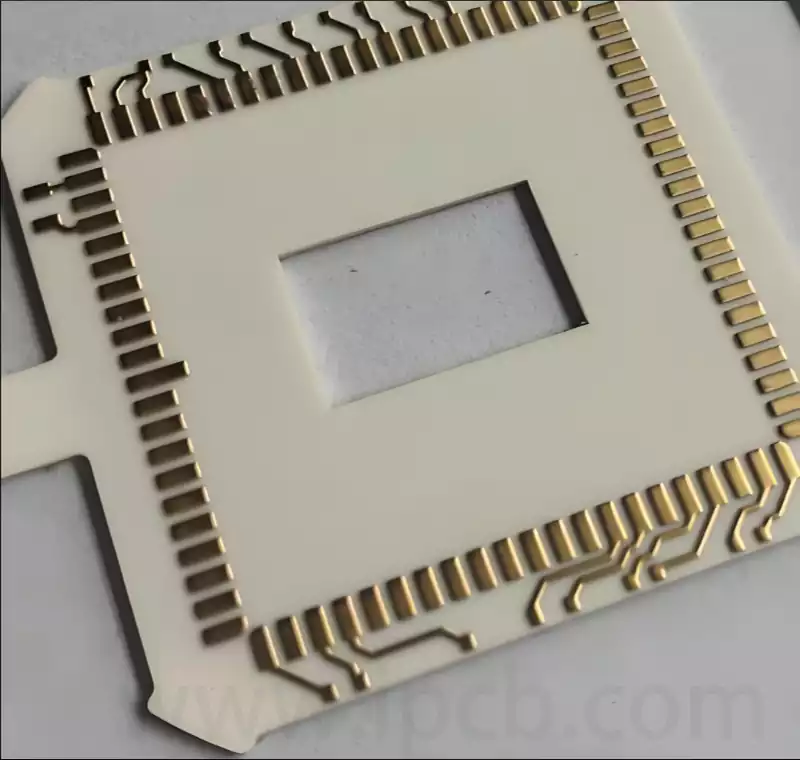

Ceramic substrate is a ceramic material made of electronic substrates, belonging to the inorganic materials, usually with alumina (Al2O3), aluminium nitride (AlN) and silicon nitride (Si3N4) as the main component, ceramic substrate has good thermal conductivity, high frequency and high temperature stability and other characteristics, widely used in high-power, high-frequency and high-temperature and other harsh environments of the electronic equipment.

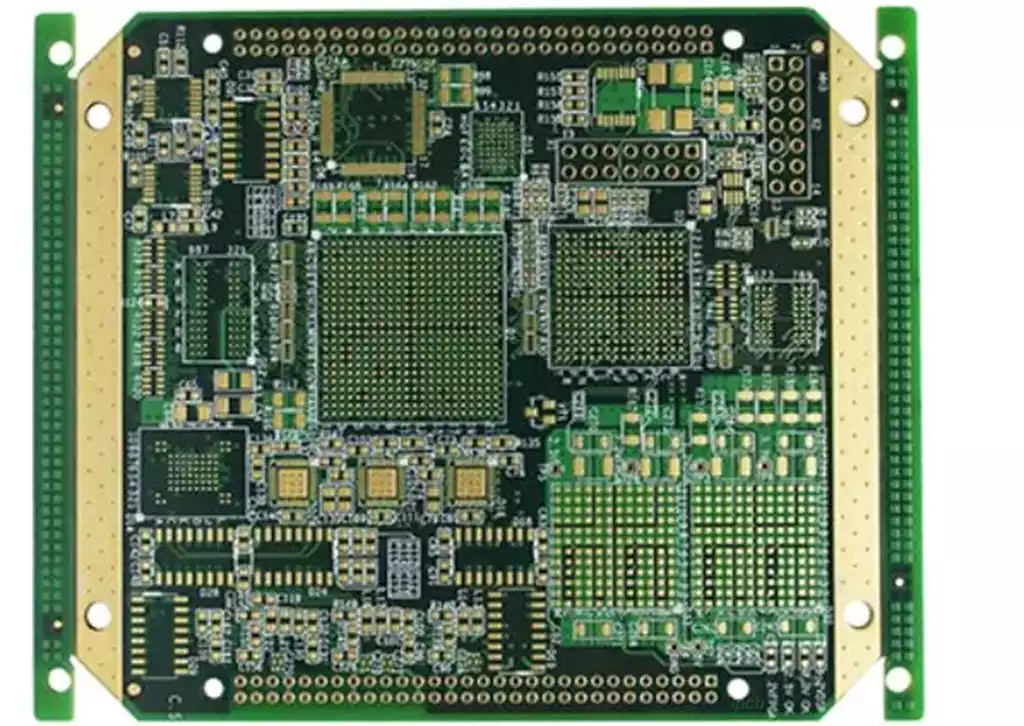

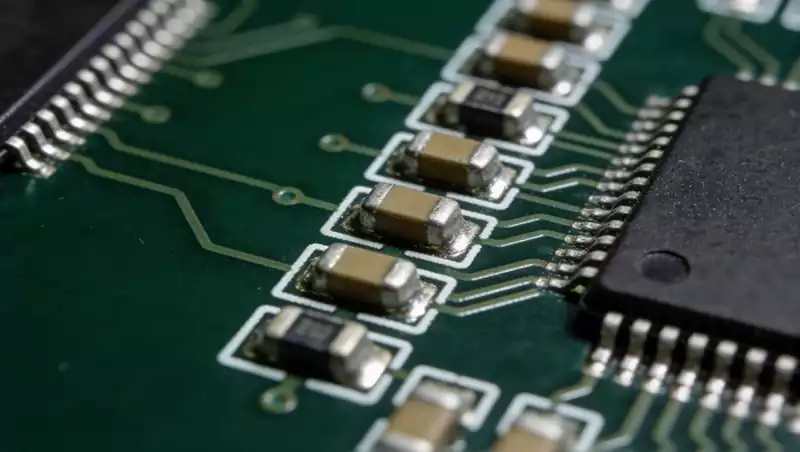

PCB board (Printed circuit board), refers to the printed circuit board, is a kind of insulating base material as the basis, above the distribution of conductive patterns of the electronic substrate, according to the number of layers of different PCB board can be divided into a single-panel, double-sided boards and multilayer boards, PCB boards have a good design flexibility, low cost and production is simple and so on. It is the most commonly used basic type in the electronics industry today.

Advantages of Ceramic Circuit Boards over Traditional Circuit Boards

Traditional circuit boards, with low thermal conductivity, poor insulation, etc., are less suitable in areas that require heat dissipation, high frequency, and high insulation. Ceramic circuit boards have advantages over conventional circuit boards:

- Higher thermal conductivity; ceramic circuit board thermal conductivity of 25w ~ 170w, the traditional circuit board less than 3 w

- More compatible with the coefficient of thermal expansion; ceramic circuit boards with a low coefficient of thermal expansion, and more compatible with the chip, do not want to generate thermal stress of traditional circuit boards, affecting the service life.

- More secure, lower resistance of the metal film layer;

- Good solderability of the substrate, high temperature use; ceramic circuit boards can be multi-layer welding, solderability, high temperature resistance.

- Good insulation;

- Low high frequency loss;

- High-density assembly is possible;

- Contains no organic components, resistant to cosmic rays, high reliability and long service life in aerospace;

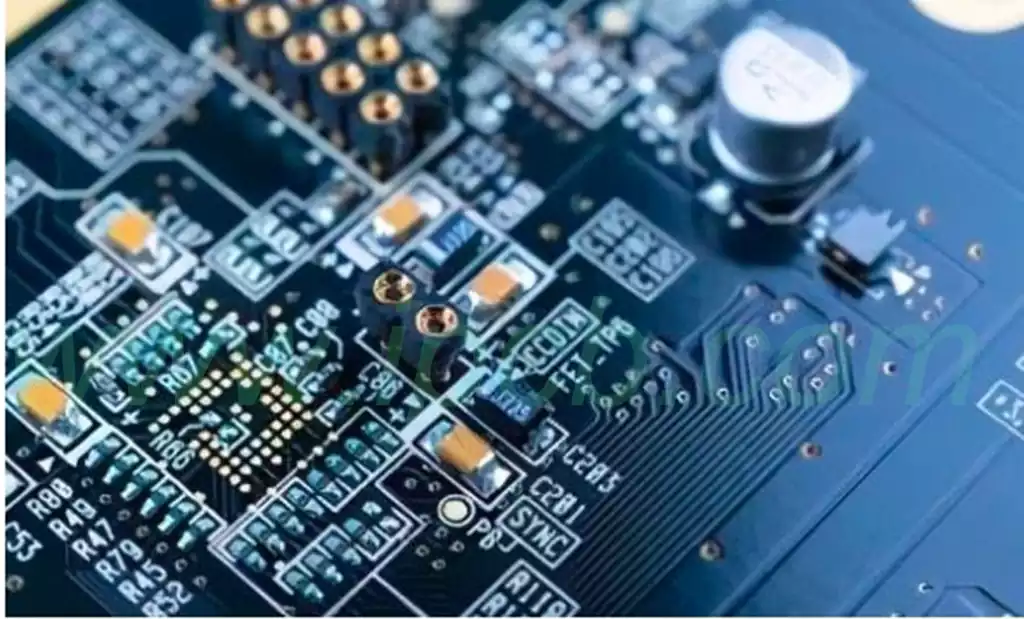

- The copper layer does not contain oxide layer, can be used in a reducing atmosphere for a long time ceramic circuit board with high thermal conductivity, high insulation properties, chemical stability and thermal stability excellent organic substrate does not have the performance, there is a distinction between the traditional FR4 substrate or metal substrate, is a new generation of large-scale integrated circuits as well as power electronic modules, the ideal packaging material.

Why is ceramic substrates more expensive than ordinary PCB:

Substrate material cost: ceramic substrates mainly use alumina or aluminium nitride and other ceramic materials, the cost of these materials is higher than the traditional FR-4 glass fibre board or other organic materials.

High process technology requirements: ceramic PCB manufacturing process is more complex, such as LTCC (low-temperature co-fired ceramics), HTCC (high-temperature co-fired ceramics), DPC (Direct Copper Plating), DBC (Direct Bonding Copper) and other technologies, which have higher manufacturing costs.

Large investment in production equipment: the production of ceramic substrates requires special equipment and technology, and the acquisition and maintenance costs of such equipment are high.

Lower design flexibility: Compared with ordinary PCBs, ceramic substrates are less flexible in design, which also increases their manufacturing costs.

Material utilisation: Ceramic PCBs have lower material utilisation in the manufacturing process, especially for larger sized ceramic boards, which also increases the cost.

With its excellent material properties and manufacturing process, ceramic substrates show unique advantages in applications with stringent requirements for heat dissipation, high frequency and high reliability. Although their production costs are relatively high, their excellent performance in extreme environments makes them ideal for new generations of high-performance electronic devices and power modules.