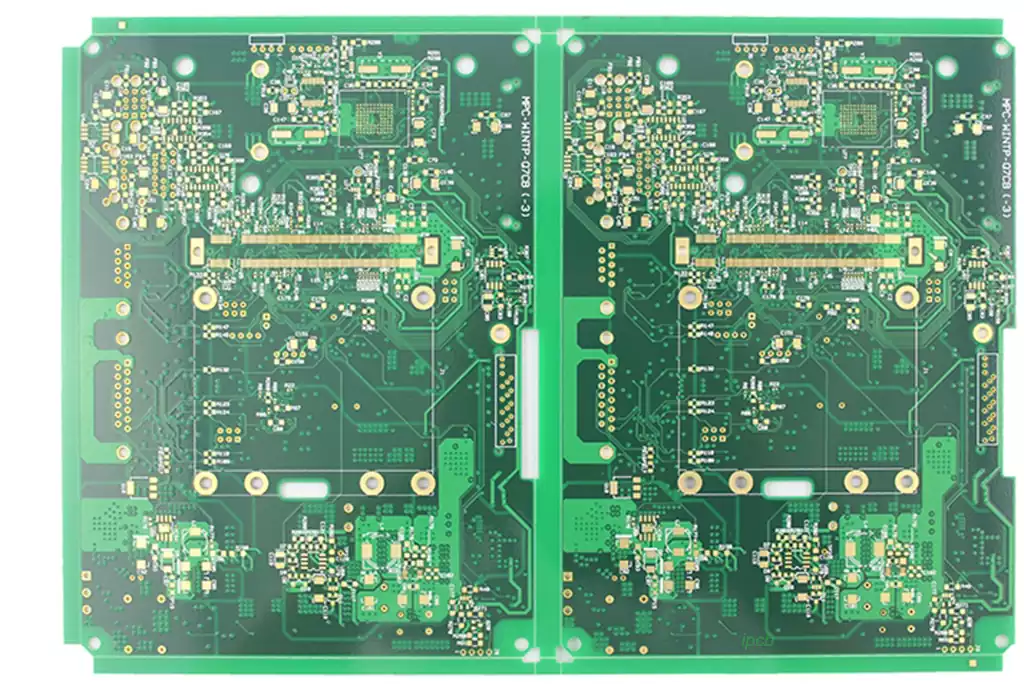

The circuit board spacers are key components in the connection between the circuit board and its components.Often placed at the bottom of the board’s component pads, they provide cushioning and support for the components and compensate for height variations and small deviations in position between components to ensure that the board’s components are securely and reliably connected. In addition,the spacer can also effectively disperse the heat and voltage generated by the circuit board,and play a role in protecting the components and circuit boards from damage.

Circuit board spacers are known by a variety of names depending on the application, some common ones being:

Printed Circuit Board Spacer -The term ‘printed circuit board’ is another way of saying ‘printed circuit board’ (Printed Circuit Board,or PCB),so circuit board spacers are also figuratively known as printed circuit board spacers.This term is commonly used in the field of circuit board manufacturing.

Printed Circuit Board Spacer -A printed circuit board spacer is a spacer that is placed underneath an electronic component and is made of an organic polymer composite material.This name is popular in the electronic component manufacturing industry.

Gap Filler Shims -Gap filler shims are specifically designed to fill small gaps or voids between circuit boards and components.This designation is more common in the field of precision machining.

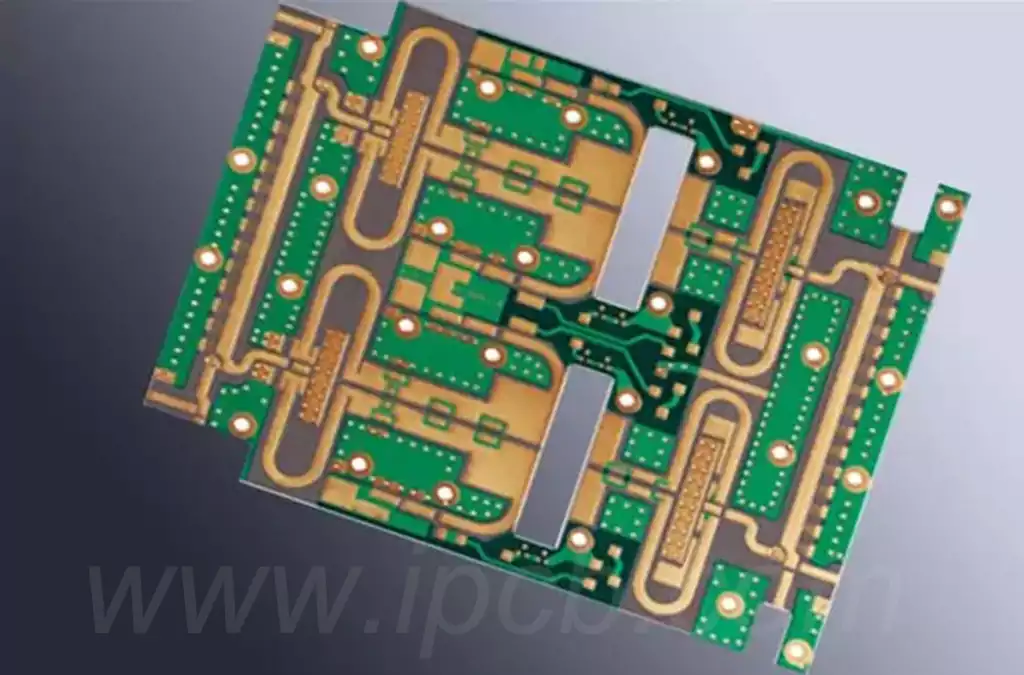

Performance Criteria for Circuit Board Spacers

Current Isolation: Circuit board spacers need to have excellent current isolation characteristics to prevent a direct current connection between the board and the external housing.

Conductivity:Certain shims need to be able to conduct current to assist in the transfer of signals between the board and other components.

High Temperature Stability:Electronic equipment generates heat during operation,and the gasket material needs to be able to withstand high temperatures without deformation or failure.

Wear resistance and durability:Gasket materials need to have excellent wear resistance to ensure their long life.

Common circuit board gasket materials and their characteristics

Rubber gaskets:Rubber gaskets are known for their ability to insulate against electrical currents and their resilience to withstand certain pressures and vibrations.However,it is prone to aging and deformation at high temperatures and has limited heat resistance.

Silicone gaskets:Silicone gaskets excel in heat resistance and current isolation,maintaining stable performance over a wide range of temperatures. In addition, it has excellent abrasion and tear resistance.

Polyester Film Shims:Polyester film shims offer excellent current isolation and a low coefficient of friction,making them suitable for applications that require high precision and high abrasion resistance.However,it has relatively poor performance in high temperature environments.

Nylon shims:Nylon shims have high strength and abrasion resistance,,as well as the ability to conduct a certain amount of current. However, its current isolation performance is relatively weak,the choice should be considered according to specific needs.

Circuit board spacers,as an important component connecting the circuit board and its components, play a vital role in the stability and reliability of electronic equipment. With the continuous development of electronic technology, the application of circuit board spacers is also more and more extensive, in the choice of spacer materials, you need to take into account the performance of the material, the cost and production requirements to ensure that the spacer can meet the high standards and stringent requirements of electronic equipment.