With the rapid development of communication technology, high-frequency bandpass filters (HF Bandpass Filter) are increasingly used in wireless communication, radar, audio processing and other fields.

As an electronic component that allows signals in a specific frequency band to pass through and suppresses signals in other frequency bands, high-frequency bandpass filters occupy an important position in modern circuits. Especially in circuits with high-speed signal transmission, the role of hf bandpass filter pcb is particularly prominent.

Basic principles of HF bandpass filter PCB

A bandpass filter is a filter that combines the characteristics of low-pass and high-pass filters. It can pass a specific frequency range (called bandwidth) while suppressing signals below or above that range. Specifically, a bandpass filter consists of two main parts: a high-pass filter and a low-pass filter. A high-pass filter allows signals above a certain frequency to pass through, while a low-pass filter allows signals below a certain frequency to pass through. When these two are combined, a bandpass filter is formed. The operating frequency range of a bandpass filter is its “bandwidth”, which can filter out noise and unwanted signals outside the frequency range.

Bandpass filters are often used in wireless communication systems to eliminate interfering signals in the spectrum and ensure the stability of the system and the quality of the signal. With the continuous advancement of technology, the performance requirements for high-frequency bandpass filters are getting higher and higher, especially in high-speed circuit design.

Design considerations for high-frequency bandpass filters pcb

In high-frequency circuits, designing an efficient high-frequency bandpass filter is not only about selecting suitable components, but also about considering multiple factors, especially the design of the circuit board.

Selecting the right material

The performance of a high-frequency bandpass filter is closely related to its material, especially the material of the PCB (Printed Circuit Board). The dielectric constant, loss factor and thermal stability of different materials will affect the performance of the filter. Common high-frequency PCB materials include FR4, PTFE (polytetrafluoroethylene), Rogers, etc. Selecting the right material can effectively reduce signal loss and improve the efficiency of the bandpass filter.

Design optimization

The design of high-frequency bandpass filters needs to consider multiple parameters, such as center frequency, bandwidth, insertion loss, reflection loss, etc. Accurate calculations and simulations are required during design to ensure that the filter performance is optimal. Using electromagnetic simulation software can help designers optimize the circuit during the design process to avoid the impact of design defects on performance.

Interlayer connection

High-frequency circuits have extremely high requirements for signal transmission, and any small distortion will affect the performance of the entire system. When designing the PCB of a high-frequency bandpass filter, special attention should be paid to the connection between different layers. In order to avoid signal interference, different power and ground layers are usually used to separate the signals. Proper interlayer connection design can not only reduce signal loss, but also improve the anti-interference ability of the system.

Routing layout

The routing design of high-frequency circuits is crucial. Since the propagation speed of high-frequency signals is close to the speed of light, the layout of the lines should be as simple and straight as possible, avoiding too many turns and long connections. The routing should be kept symmetrical as much as possible to avoid signal imbalance caused by asymmetric layout. In addition, the routing width and spacing also need to be accurately calculated according to the frequency and dielectric material.

Anti-interference design

High-frequency circuits are susceptible to electromagnetic interference (EMI), so when designing bandpass filter circuit boards, special attention should be paid to anti-interference design. The impact of external interference on the circuit can be reduced by adding shielding layers, using filters, and adding decoupling capacitors.

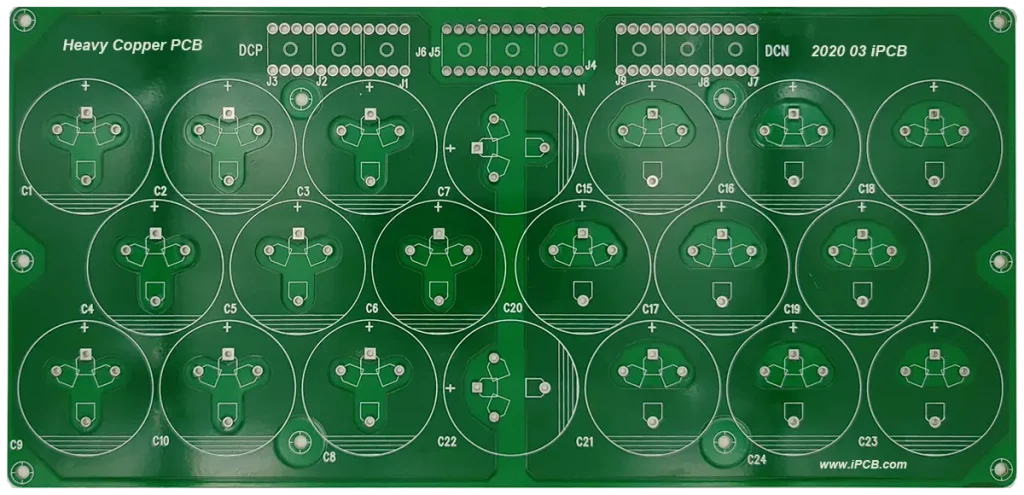

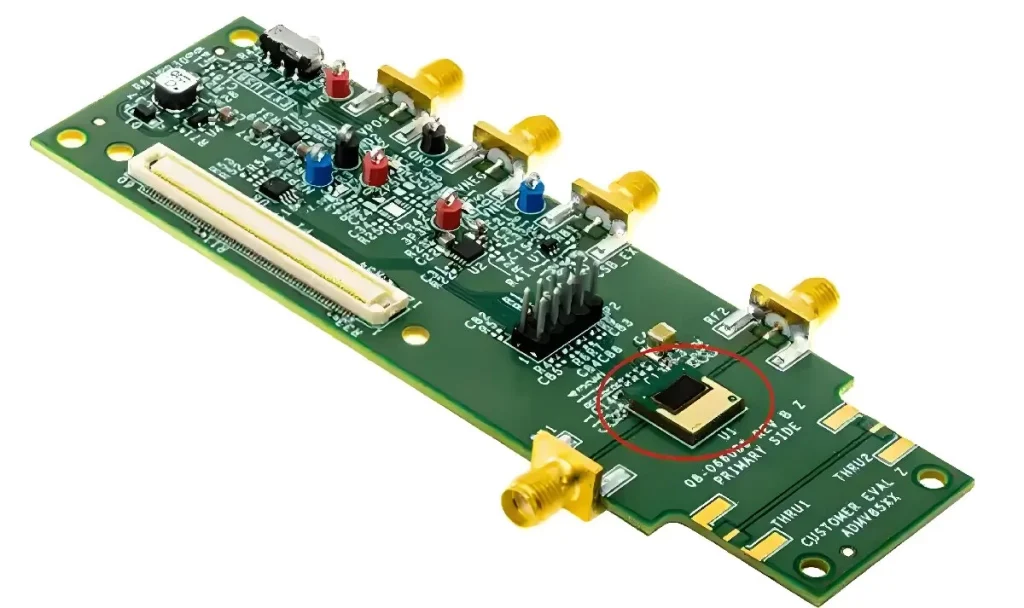

Manufacturing of high-frequency bandpass filter circuit boards

The manufacturing process of high-frequency bandpass filter circuit boards is relatively complex, requiring high process precision, reasonable material selection, and strict control of the processing process. Generally, the manufacturing process of high-frequency PCB requires multiple links such as fine circuit etching and surface treatment.

Circuit Etching

The circuit etching of high-frequency bandpass filter circuit boards requires special attention to accuracy, especially in the transmission of high-speed signals, any tiny etching error will affect the integrity of the signal. For this reason, commonly used high-frequency circuit board manufacturing methods include laser etching, chemical etching, etc., which can ensure the accuracy and high quality of the etching process.

Surface Treatment

The surface treatment of high-frequency bandpass filter circuit boards is also crucial, especially in high-frequency signal transmission, the surface smoothness directly affects the transmission quality of the signal. Common surface treatment methods include HASL (hot air leveling), ENIG (chemical nickel gold), OSP (organic cover layer), etc., which can effectively reduce signal loss.

Assembly and Testing

The assembly process of high-frequency bandpass filters requires precise operation to ensure that each component is correctly placed and well connected. Testing is a key link to ensure the performance of the circuit board. By comprehensively testing the performance of the circuit, problems in design or manufacturing can be discovered in time. Common test methods include frequency response test, insertion loss test, etc.

Application fields of high-frequency bandpass filters

High-frequency bandpass filter circuit boards are widely used in many fields, especially in wireless communication and radio frequency systems, where their role is indispensable.

Wireless communication

In wireless communication, bandpass filters are used to select the frequency range of received signals to ensure the clarity and stability of signals. It can effectively filter out unwanted frequency band interference signals and improve the anti-interference ability of communication systems. Especially in high-speed communication networks such as 4G and 5G, high-frequency bandpass filters are important components to ensure signal quality.

Radar system

In radar systems, bandpass filters are used to select the frequency range of radar signals and remove stray signals and noise. Due to the high frequency of radar signals, the design of bandpass filters must take into account the characteristics of high-frequency signals to ensure clear transmission of signals.

Audio processing

In the field of audio processing, bandpass filters are used to select specific audio frequency bands for processing. For example, in audio systems, bandpass filters can be used to select the intermediate frequency part, remove low-frequency and high-frequency noise, and thus improve sound quality.

Medical instruments

In medical instruments, bandpass filters are widely used in biological signal processing, such as the acquisition and analysis of electrocardiogram (ECG) and electroencephalogram (EEG) signals. Through the action of the filter, physiological noise can be effectively removed, useful signals can be extracted, and accurate data can be provided for medical diagnosis.

Challenges and solutions of high-frequency bandpass filter pcb

Although high-frequency bandpass filter circuit boards are widely used in many fields, there are still some challenges in the design and manufacturing process. These challenges are mainly reflected in the stability of the circuit, the quality of signal transmission and the accuracy of the design. In order to solve these problems, engineers have adopted a variety of effective technical means.

Attenuation and loss of high-frequency signals

High-frequency signals often experience large signal attenuation and loss during transmission, which is mainly due to the electromagnetic loss of PCB materials and the impedance matching of the traces. When designing high-frequency bandpass filter circuit boards, special attention should be paid to the signal transmission path to avoid signal loss in the circuit as much as possible. By selecting low-loss PCB materials, such as the high-frequency materials of the Rogers series, engineers can effectively reduce the signal loss of the circuit board.

Solution:

In order to reduce the loss, engineers can optimize the trace design of the circuit board, such as reducing the bending angle of the line, increasing the area of the ground layer, or using materials with lower temperature coefficients to reduce signal loss. In addition, the use of higher-quality surface treatment processes, such as ENIG treatment, can also effectively reduce the impedance fluctuation of the circuit, thereby improving the stability of signal transmission.

Electromagnetic interference (EMI) problem

High-frequency circuits are easily interfered by external electromagnetic fields, which can affect the normal operation of the circuit and cause signal distortion or loss. Especially in the application of high-frequency bandpass filter circuit boards, EMI problems are particularly prominent.

Solution:

In order to reduce electromagnetic interference, designers can use shielding technology to wrap the circuit with metal shells or conductive materials. In addition, by reasonably laying out the power supply and ground layer, the impact of electromagnetic interference can be effectively reduced. The coupling between the power supply and the ground layer can also provide better anti-interference performance and prevent external signal interference from entering the filter circuit.

Impedance matching problem

Impedance matching is a crucial issue in the design of high-frequency bandpass filter circuit boards. Impedance mismatch will cause signal reflection, thereby affecting the transmission quality of the signal. When designing, it is necessary to ensure that the input and output impedances of each component are consistent.

Solution:

Common methods to solve impedance matching problems include using differential signal transmission lines, reasonably laying out signal paths, and using appropriate terminal resistors. Designers can also simulate impedance matching through simulation tools to ensure the impedance matching of the circuit at different operating frequencies.

Impact of temperature changes on performance

The performance of high-frequency bandpass filter circuit boards is often affected by temperature changes. In high or low temperature environments, the dielectric constant, conductivity and other properties of the material will change, thus affecting the operating frequency and bandwidth of the filter.

Solution:

In order to overcome the impact of temperature changes on performance, engineers can choose materials with higher temperature stability, such as PTFE or ceramic substrate materials, which have good thermal stability and can maintain stable electrical properties over a wide temperature range. At the same time, temperature compensation circuits can be added during design to automatically adjust the working state of the circuit to ensure the stable operation of the high-frequency bandpass filter under different temperature conditions.

Future development trends

With the continuous development of wireless communication technology, radar technology and consumer electronics, the market demand for high-frequency bandpass filter circuit boards is growing. In order to meet these needs, the design and manufacturing technology of high-frequency bandpass filters are also constantly improving.

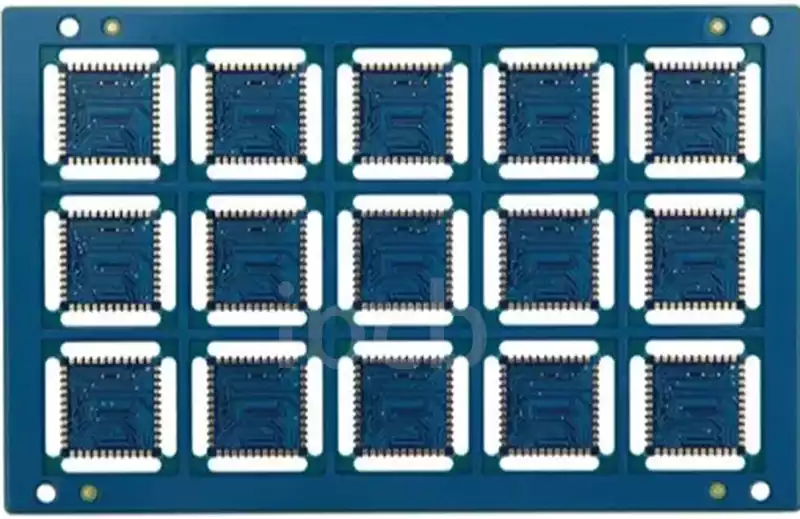

Integration and miniaturization

The future high-frequency bandpass filter circuit boards will develop in the direction of integration and miniaturization. As electronic devices become increasingly demanding in terms of size, engineers are constantly exploring ways to integrate filter functions into smaller, more compact circuits. The development of integrated circuit (IC) and system-in-package (SiP) technology has made it possible to integrate bandpass filters. By using more efficient designs and reducing the number of components, future bandpass filters will have smaller sizes and higher performance.

Multi-band bandpass filters

In many applications, especially in modern communication systems, signal filtering is often required on multiple frequency bands. Future bandpass filters may not only be filters for a single frequency band, but filters that can handle multiple frequency bands at the same time. For example, in 5G communication systems, due to the complexity of the spectrum, more and more multi-band filters are required.

Solution:

By adopting multi-layer circuit design and more advanced multiplexing technology, the functions of multiple bandpass filters can be realized on a single circuit board. This will provide more efficient solutions for wireless communications, satellite communications and other fields, reducing the need for multiple filter circuit boards.

Adaptive bandpass filters

With the development of wireless communications and radar technology, the requirements for signal processing are getting higher and higher, especially the adaptability to signals in dynamic environments. In the future, high-frequency bandpass filters may have adaptive capabilities, automatically adjusting the operating frequency band according to environmental changes to improve the efficiency of signal processing.

Solution:

The implementation of adaptive bandpass filters requires a combination of digital signal processing (DSP) technology and intelligent control systems. Through sensors and feedback mechanisms, the filter can sense changes in the environment in real time and automatically adjust its bandwidth and center frequency to adapt to different working environments.

Conclusion

High-frequency bandpass filter circuit boards play a vital role in modern electronic technology and are widely used in communications, radar, audio processing and other fields. With the continuous advancement of technology, the design and manufacture of high-frequency bandpass filters face more challenges, and new technologies and solutions have also emerged.

In order to meet the high-performance requirements of high-frequency circuits, designers need to continuously optimize the design and improve the stability, signal transmission quality and anti-interference ability of the circuit board. In the future, high-frequency bandpass filter circuit boards will develop in the direction of integration, multi-band and adaptation, providing support for more high-tech applications.