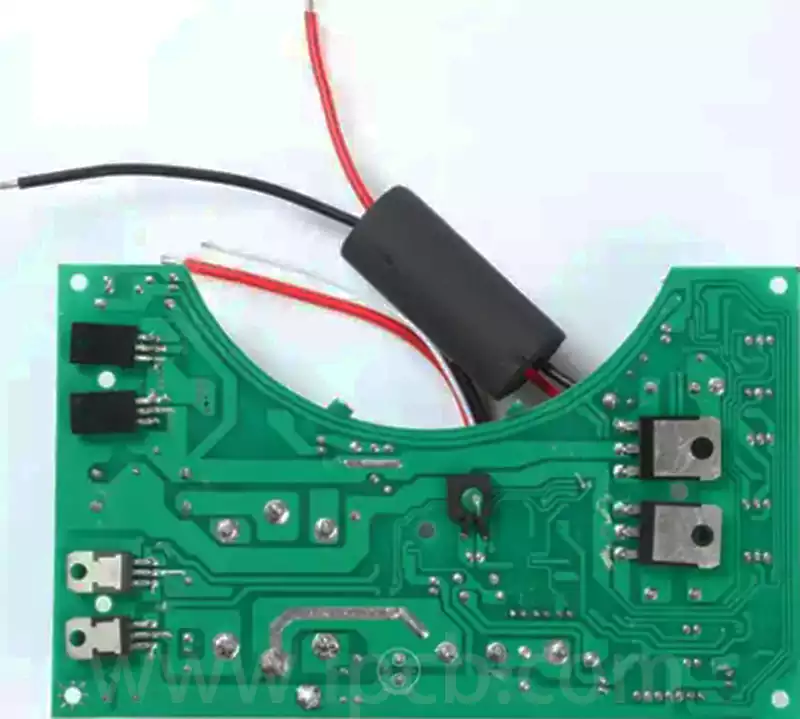

Automotive circuit board, full name of automotive printed circuit board, is a kind of electronic products using printing technology to print the copper foil line on the insulated substrate. It connects various electronic components such as resistors, capacitors, chips, etc. together through specific circuit patterns to achieve the transmission and processing of electronic signals, thus ensuring the normal operation of various functional systems in the car. For example, the circuit board in the engine control module (ECU) is responsible for collecting signals from various types of sensors, sending commands to the actuator after analysis and processing, and accurately controlling the engine’s fuel injection, ignition timing and other key parameters to ensure efficient and stable engine operation.

It is usually composed of substrate, conductive path, circuit components and so on. The substrate material of the automotive pcb is mainly used for high temperature, heat, humidity and corrosion resistance to cope with the various challenges of the automotive environment. The substrate is usually printed with conductive paths, these copper conductive paths are known as printed circuits, which connect circuit components and form a path for current. Circuit components, such as resistors, capacitors, inductors, diodes, transistors, etc., are key components of automotive circuit boards, whether they are controlling the car’s power system or functions such as environmental sensing and navigation.

The main functions of automotive circuit board include:

- Control and monitoring: managing various automotive systems, such as engine control, braking systems, airbags, etc.

- Communication: Ensure effective communication between various systems within the vehicle.

- power distribution: reasonably distribute power to ensure the normal operation of various electronic devices.

Characteristics of automotive circuit board:

- High reliability: work stably in the complex automotive environment.

- Strong anti-interference ability: not affected by external electromagnetic interference.

- High temperature and vibration resistance: adapt to the working conditions of the car.

The application scope of automotive circuit board

The complexity of modern automobiles is far beyond the scope of traditional mechanical equipment, and automotive PCB plays an important role in a number of key areas. For example, in the power control system, automotive PCB is responsible for managing the operation of the engine, transmission, braking and other core power components; in-vehicle information systems through the automotive circuit board to achieve a variety of functions, such as navigation, communication and entertainment; safety control systems rely on the automotive printed circuit board on vehicle stability, airbags and other safety mechanisms for precise control; environmental awareness systems such as reversing radar, rain sensors and other functions, but also by the specially designed automotive circuit board to support them. Each function needs to be specially developed to meet its performance requirements of the automotive PCB to ensure stable and efficient operation of the system.

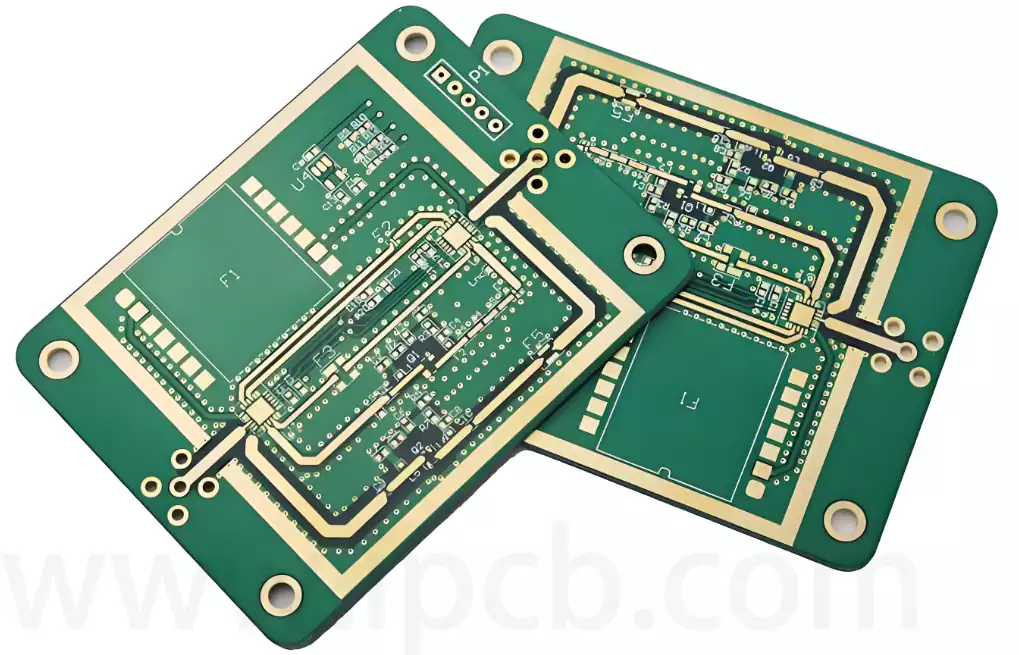

Difference between automotive PCB and ordinary PCB

- Material selection

There are some differences in material selection between automotive circuit board and ordinary PCB. Ordinary PCB boards usually use FR-4 glass fibre material, while automotive circuit board needs to choose a higher level of material, such as FR-4 HTG material with better high temperature resistance or polyimide material. This is because automotive PCB need to have better stability and reliability in high temperature environments. - Process requirements

There are also differences in process requirements between automotive printed circuit board and ordinary PCBs. Because the automotive printed circuit board needs to withstand more severe working environment and vibration shock, so its process requirements are higher. For example, automotive circuit board requires more stringent welding and protection to ensure the stability and reliability of the circuit. In addition, automotive PCB boards also need to meet the higher fire rating and corrosion resistance. - Environmental adaptability

Automotive circuit boards and ordinary PCB boards are also different in environmental adaptability. Ordinary PCB boards are mainly used in general electronic preparations, the environmental requirements are relatively low. The automotive printed circuit board needs to adapt to more complex automotive environment, such as high temperature, low temperature, humidity, vibration and so on. Therefore, automotive circuit boards need to have better resistance to high temperature, humidity and vibration. - Reliability of automotive

Automotive printed circuit boards and ordinary PCB boards in the reliability of the differences. Because the automotive PCB in the automotive electronic system to assume a more important role, so its reliability requirements are higher. Automotive circuit boards need to withstand long hours of work and harsh working environment, so it needs to have better anti-aging, corrosion resistance and anti-interference capabilities. In addition, automotive PCBs also need to pass strict reliability tests to ensure their stability and reliability under various extreme conditions.