Within the field of electronic components, ceramic capacitors occupy a significant position, with multilayer ceramic capacitor (MLCC) and single-layer ceramic capacitors (SLCC) being two common and widely applied types. Although both fall under the category of ceramic capacitors, they exhibit numerous significant differences in structure, performance, manufacturing processes, and material selection.

MLCC and SLCC are distinct ceramic capacitors:

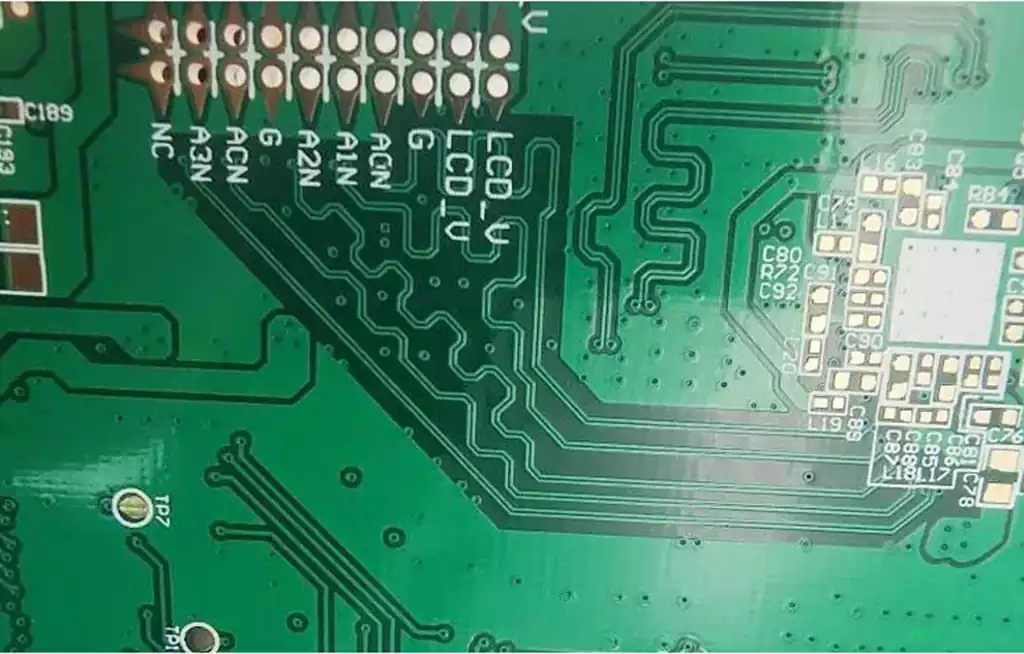

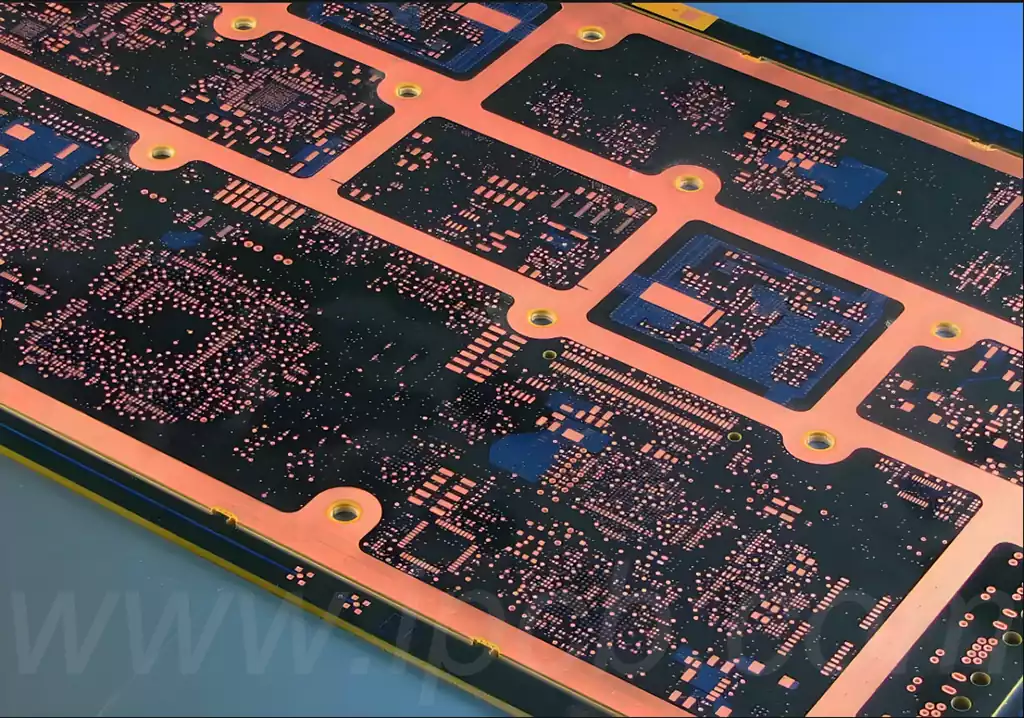

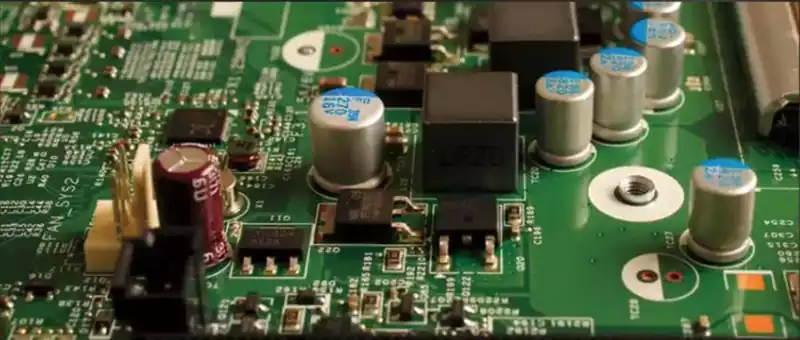

① MLCCs are formed by stacking ceramic dielectric layers with printed electrodes (inner electrodes) in an offset arrangement. These layers undergo a single high-temperature sintering process to create a ceramic chip. Metal layers (outer electrodes) are then applied to both ends of the chip, resulting in a monolithic structure often termed a monolithic ceramic capacitor. MLCCs offer advantages including compact size, high capacitance per unit volume, extended lifespan, low loss at high frequencies, and high reliability.

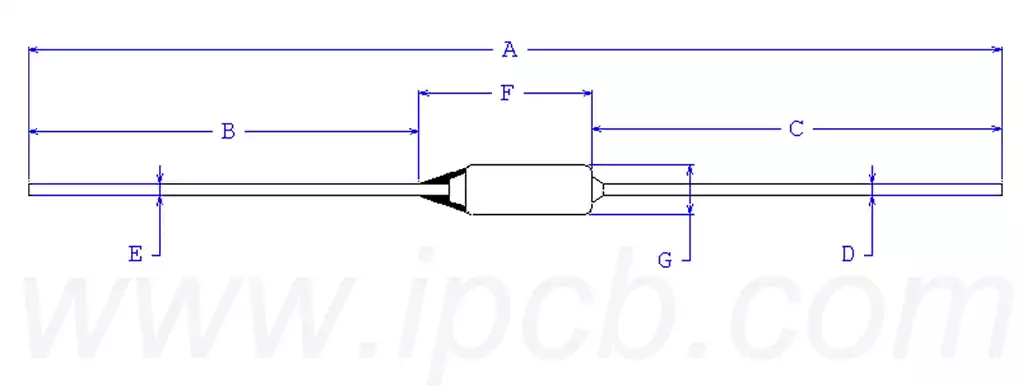

② SLCC utilises a single-layer ceramic dielectric as its core. Lead terminals are formed on both sides via thin-film processes, with a gold layer serving as the outermost electrode. Commonly termed chip capacitors, they feature a simple structure, high ceramic strength, and stable, reliable electrical performance. However, their capacitance values are relatively smaller compared to MLCCs.

Comparison of SLCC and MLCC Production Processes

Significant differences exist between the manufacturing processes of SLCC and MLCC. SLCC employs semiconductor thin-film technology, whereas MLCC does not utilise this approach. Furthermore, SLCC production does not involve co-firing the ceramic substrate with electrodes, a step essential for MLCC manufacturing.

These differing production methods naturally necessitate distinct key manufacturing equipment for each product. Primary equipment for SLCC production includes reduction atmosphere sintering furnaces and grain boundary oxidation equipment for ceramic substrate fabrication, alongside semiconductor process equipment such as sputtering machines, etching machines, lithography machines, and dicing machines. In contrast, key equipment for MLCC production comprises high-temperature sintering furnaces, ultra-thin layer flow coating machines, high-precision printing and stacking equipment, and terminal processing equipment.

Turning to material differences: ceramic materials for MLCC emploies a co-firing process for the ceramic dielectric layer and metal internal electrodes. This necessitates a ceramic powder sintering temperature below the metal electrode’s melting point, alongside resistance to reduction and re-oxidation. SLCCs, however, first sinter the ceramic dielectric layer before forming metal electrodes, meaning their ceramic powder sintering temperature is unconstrained by metal electrode melting points. To meet SLCC’s requirement for miniaturisation while maintaining high capacitance, semiconductor ceramic materials with grain boundary layers are extensively employed in production, commonly referred to within the industry as ‘Class 3 ceramics’.

Regarding metallic materials, MLCC features both inner and outer electrodes, typically employing base metals such as copper or nickel for the inner electrode and copper, nickel, or tin for the outer electrode. SLCCs, lacking an inner electrode, utilise precious metals like titanium-tungsten, platinum, or gold for their electrodes to accommodate micro-assembly via gold wire bonding.

Key Material Differences Between MLCC and SLCC

Regarding ceramic materials, MLCC employs a co-firing process for the ceramic dielectric layer and metal inner electrode. This requires the ceramic powder’s sintering temperature to be below the melting point of the metal inner electrode, while also possessing resistance to reduction and re-oxidation. Conversely, SLCC first fires the ceramic dielectric layer before preparing the metal electrodes, meaning the ceramic powder’s sintering temperature is not constrained by the metal electrode’s melting point. To achieve high capacitance properties in miniaturised SLCCs, production necessitates extensive use of grain boundary layer semiconductor ceramic materials (commonly termed ‘Class 3 ceramics’ within the industry).

Regarding metallic materials, MLCC features both inner and outer electrodes, typically employing base metals such as copper or nickel for the inner electrode and copper, nickel, or tin for the outer electrode. SLCCs lack an inner electrode; to accommodate micro-assembly via gold wire bonding, precious metals like titanium-tungsten, platinum, or gold are commonly used for the electrodes.

As quintessential representatives of ceramic capacitors, MLCC and SLCC exhibit distinct characteristics in structure, manufacturing processes, and materials. MLCC achieves high performance through complex fabrication techniques, excelling in high-frequency and high-capacitance applications. SLCC, conversely, leverages its simple structure and stable performance to establish a firm foothold in specific micro-assembly domains. Complementing each other’s strengths, these two technologies collectively propel the electronic components industry towards ever-greater heights.